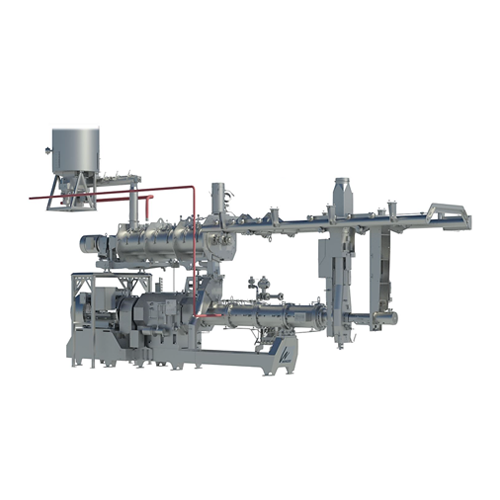

Extruder for high-volume pet food production

Maximize production efficiency with an advanced extrusion system designed for creating diverse pet foods and aquatic feeds, enhancing product innovation and ensuring consistent, high-quality output.

Processes High-Moisture Pet Foods and Aquatic Feeds

The PetFLEX™ from Wenger is a twin screw extruder engineered to optimize the production of high-moisture pet foods and aquatic feeds. With its unique screw configuration and high thermal energy design, it excels in handling varied ingredient compositions, from traditional kibble to innovative plant-based meat analogs. The extruder integrates advanced steam injection technology, ensuring consistent product density and uniformity across a wide output range, up to 11,000 kg/hr. Its intuitive control systems facilitate seamless automation and precise monitoring, supporting integration into existing production lines. The durable metallurgy enhances operational uptime and minimizes wear, offering long-term reliability. Available with customization options, it meets diverse industry needs while ensuring energy efficiency and reduced operational costs.

Benefits

- Enhances production efficiency with optimized high-moisture processing capabilities.

- Ensures consistent product quality and uniformity, minimizing rejects and waste.

- Lowers operational costs through energy-efficient thermal design.

- Increases production flexibility with versatile ingredient handling.

- Reduces maintenance and extends equipment lifespan with durable construction.

- Applications

- Hybrid products, Textured vegetable proteins, Snacks, Pet food, Aquatic feed, Meat analogs, Protein crisps, Breadcrumbs, Rte breakfast cereals

- End products

- Pea protein crisps, Semi-moist dog treats, Cornflakes, Dental dog treats, Soy-based breakfast sausages, Floating fish pellets, High fresh meat inclusion kibble, Sinking aquaculture feeds, Slow-sinking shrimp feed, Traditional kibble, Filled pet snacks, Plant-protein hybrid snacks, Multi-grain breadcrumb coatings, Plant-based chicken nuggets

- Steps before

- Grinding, Emulsification, Ingredient preparation, Preconditioning

- Steps after

- Coating, Enrobing, Drying, Cooling, Packing

- Input ingredients

- limited ingredients diets, fresh meat, semi-moist ingredients, unconventional ingredients

- Output ingredients

- traditional kibble, premium kibble, high fresh meat kibble, treats, micro size aquatic feeds

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Capacity

- Up to 11, 000 kg/hr

- Motor Size

- 300-600 HP

- Steam Injection

- Up to 12% in pre-conditioner

- Shear Application

- Medium and High Shear

- Thermal Energy

- High Thermal Energy Design

- Product Uniformity

- Superior Product Uniformity and Density Control

- Extruder Type

- Twin Screw

- Working Mechanism

- Twin Screw Extrusion

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy Efficiency

- High thermal energy design

- Fresh Meat Inclusion

- Optimized for slurry

- Alternative Ingredients Flexibility

- High

- Output Capacity

- Up to 11, 000 kg/hr

- Modular Design

- Interchangeable screw configurations

- Interactive Control Interface

- Intuitive

- Steam Injection

- Optimized in barrel

- Product Range Versatility

- Wide

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fresh meat inclusion options

- Yes

- Flexibility for unconventional ingredients

- Yes

- High fresh meat inclusion

- Yes

- Durability and wear resistance

- High

- Thermal energy optimization

- High

- Steam injection adaptability

- Up to 12%

- Product range

- Traditional kibble, semi-moist, high fresh meat inclusion, treats

- Machine footprint

- N/A

- Discharge method

- Standard / Custom

- Control panel type

- Intuitive / Interactive

- Screw configuration

- Unique twin screw

- Durability

- Enhanced wear life

- Preconditioner Steam Levels

- Up to 12% using Wenger HIP