Meat injection system for pet food production

Integrate fresh meat seamlessly into your pet food production line, enhancing nutritional value and product appeal with precise meat injection technology.

Injects Fresh Meat into Extruded Pet Foods

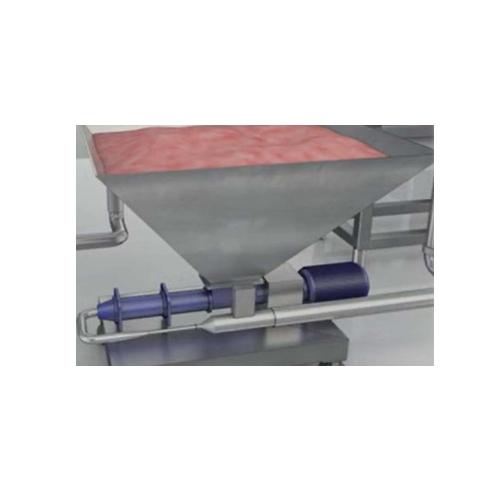

The Meat Injection System from Wenger Manufacturing is tailored for pet food producers aiming to enhance their extruded products with fresh meat, ensuring superior protein content and nutritional value. Its distinctive progressive cavity pump and flow meter guarantee consistent slurry injection into the extrusion process. Designed with a 200-liter stainless steel hopper, it supports prolonged runs and continuous operation, ideal for producing high-protein kibble, semi-moist dog food, and meat-filled treats. Easily integrated into existing production lines, it offers reliable performance and manual operation flexibility. The system is constructed for easy cleaning and maintenance, promoting hygiene and reducing downtime.

Benefits

- Enhances product appeal with consistent, high-quality fresh meat inclusion.

- Increases production efficiency with reduced manual intervention.

- Minimizes contamination risks through easy-to-clean design.

- Supports high-volume runs with extended storage capacity.

- Ensures reliable product consistency with precise slurry flow control.

- Applications

- Pet treats, Pet food, Semi-moist pet food, Traditional kibble, Extruded products, High fresh meat inclusion

- End products

- Dental chews, Nutrient-rich extruded pellets, Fresh meat-infused kibble, Meat-filled pet treats, High-protein kibble, Semi-moist dog food, Bacon-flavored dog treats

- Steps before

- Grinding, Mixing, Preconditioning

- Steps after

- Drying, Coating, Packing

- Input ingredients

- fresh meat, slurry

- Output ingredients

- extruded pet food, kibble, semi-moist pet food, high fresh meat inclusion treats, filled treats, dental treats

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Capacity

- 200 liters

- Automation

- Manual / PLC

- Cleaning method

- Easily cleanable

- Feed type

- Slurry

- Mobility

- Movable support stand on wheels

- Flow control

- Progressive cavity pump and flow meter

- Working mechanism

- Progressive cavity pump

- Integrated steps

- Flow meter for slurry consistency

- Automation level

- Manual / PLC

- CIP/SIP

- Cleanable design

- Changeover time

- Movable support stand

- Batch vs. continuous operation

- Continuous

- Cleanability

- Easily cleanable design

- Hopper Size

- 200 liters

- Material

- Stainless Steel

- Support Stand

- Movable on wheels

- Design

- Easily cleanable

- Material

- Stainless steel