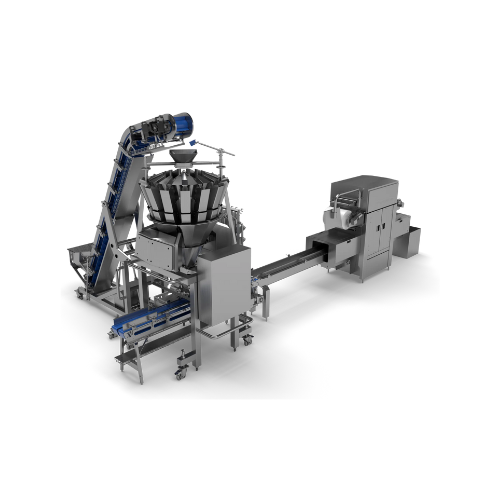

Flexible weighing and packaging solution for small batch producers

Streamline your packaging line with a mobile solution tailored for efficient weighing and packing, perfect for enhancing automation in diverse food production environments.

Automates Weighing and Packing for Food Production

The Flexi-Line from Cabinplant is an innovative solution designed to streamline your food production operations by automating weighing and packing processes. This equipment stands out with its flexibility and mobility, allowing seamless adaptation to varied production needs. It uses a multihead weigher along with a tray conveyor and product elevator for efficient handling of solid foods like salmon portions, chicken breast fillets, and ready-to-eat meals. With a capacity to handle up to 55 packs per minute, it integrates effortlessly into existing conveyor lines, improving automation and scaling capabilities. Engineered for small batch producers, the Flexi-Line features customizable multihead weigher configurations to match your specific product requirements. Constructed with easy-to-clean materials, it supports both vibratory and screw feeding principles, offering precise weight control and minimized give-away. Its compact design reduces your production footprint, while enhancing operational flexibility, suitable for packaging departments focused on enhancing efficiency and reducing manual labor.

Benefits

- Increases production efficiency by automating manual packaging tasks.

- Enhances mobility, allowing quick transitions between product lines.

- Customizable and scalable design supports varied production needs.

- Reduces labor costs and minimizes errors with automated workflows.

- Small footprint optimizes space in production facilities.

- Applications

- Seafood, Dairy food, Berries, Convenience food, Pet food, Meat, Vegetables, Poultry, Fish

- End products

- Chicken breast fillets, Beef steak packs, Dry dog food, Shrimp trays, Salmon portions, Cheese blocks, Ready-to-eat meals, Berry mix packets, Mixed vegetable trays

- Steps before

- Preparation, Mixing, Thawing, Grading/Sorting

- Steps after

- Packing, Heat treatment, Cooling/Freezing, Glazing

- Input ingredients

- premade trays, thermoformer, dry products, frozen products, hot products, chilled products, fresh products, sticky products, marinated products

- Output ingredients

- weighed products, packed products, thermoformed trays, premade trays

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Speed

- Up to 55 PPM

- Speed (Processed hot/chilled)

- Up to 45 PPM

- Speed (Fresh/Sticky/Marinated)

- Up to 40 PPM

- Tray Size

- 90-300 x 100-400 x 20-80 mm

- Automation

- PLC-controlled, Manual / Auto dosing

- Multihead Weigher Type

- MHW 10-14, MHW 30-10, MHW 30-14

- Hopper Size

- 10 / 30

- No. of Heads

- 14 / 10 / 14

- Feeding Principle

- VF (Vibratory Feeding) / SF (Screw Feeding)

- Packing Type

- Premade trays / Thermoformer

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Mobility and Flexibility

- Mobile and flexible design

- Cleanability

- Designed for easy cleaning

- Compact footprint

- Small footprint

- Discharge method

- Product elevator

- Mobility

- Mobile system

- Flexibility

- Customizable configurations

- Tray Size

- WxLxH, mm 90-300 x 100-400 x 20-80

- Control panel type

- Customizable

- Workflow customization

- Yes, customizable

- Scalability

- Customizable and scalable

- Tray size configurations

- Customizable (90-300 x 100-400 x 20-80 mm)

- Multihead weigher configuration

- VF (Vibratory Feeding) / SF (Screw Feeding)

- Mobility

- Designed for easy movement and accessibility