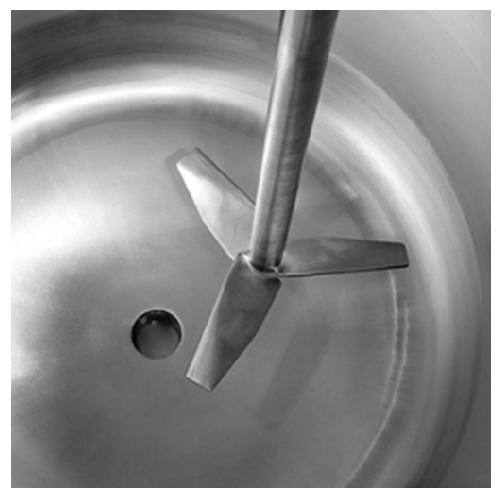

Static impellor mixer for homogeneous gelatin solutions

Achieve lump-free mixtures in your bakery production line with precision-engineered mixers, designed to efficiently hydrate dry ingredients with low viscosity liquids, optimizing consistency and quality of your products.

Mixes and Hydrates Ingredients Efficiently

The TFT-Impellor mixer from Tanis Food Tec specializes in precision mixing for the food and bakery industries. This batch mixer features a static impellor design that delivers consistent, lump-free mixtures by homogenizing dry ingredients with low viscosity liquids like gelatin and water. Ideal for crafting gelatin desserts, cake batters, and custards, it’s equipped with a jacketed tank for precise temperature control, ensuring optimal conditions throughout the mixing process. Its design allows seamless integration into your production line, whether mounted directly on a holding tank or connected to transport systems using an optional bottom-mounted transfer pump for extended transfer. Engineered for efficient operation, it supports flexible connectivity with third-party dosing systems, load cell weighing, and mass flow measurements, facilitating precise ingredient handling. Moreover, the CIP-capable design reduces downtime and ensures hygiene compliance, accommodating the high standards required in food production environments. This adaptable equipment can be tailored with Tanis Food Tec’s engineering support, ensuring it meets your specific production requirements.

Benefits

- Ensures consistent product quality with lump-free mixing capabilities.

- Minimizes energy usage with precise temperature regulation.

- Reduces operational downtime through CIP-capable design.

- Facilitates seamless integration with existing dosing and weighing systems.

- Supports diverse food production requirements with adaptable configurations.

- Applications

- Liquid mixing, Gelatin solutions, Bakery ingredients, Food powders, Dry ingredients

- End products

- Dough mixes, Gelatin desserts, Custards, Pastry creams, Bakery fillings, Cake batters

- Steps before

- Ingredient Weighing, Ingredient Feeding

- Steps after

- Gravity Emptying, Pumping to Holding Tank, Mass Flow Measurement

- Input ingredients

- dry ingredients, low viscosity liquids, gelatin, water

- Output ingredients

- lump-free mix, hydrated mixture, mixed solution

- Market info

- Tanis Food Tec is known for designing and manufacturing custom-engineered food processing equipment, specializing in innovative solutions for the confectionery, bakery, and dairy industries, with a reputation for quality, precision, and reliability in delivering tailored production lines.

- Mixer type

- Static impellor

- Mixing type

- Batch mixing

- Temperature control

- Jacketed tank

- Discharge method

- Gravity or transfer pump

- CIP capability

- Yes

- Integration compatibility

- Compatible with third-party dosing systems

- Weighing system

- Load cell

- Mass flow measurement

- Integration possible

- Performance

- High on gelatin/water solutions

- Working mechanism

- Batch mixing

- Integrated steps

- Mixing and hydrating

- CIP principles

- CIP-able design

- Batch vs. inline flow

- Batch operation

- Modular design

- Optional transfer pump

- Temperature control

- Jacketed tank

- Communication capability

- Connect with third-party dosing systems

- Weighing system

- Load cell weighing system

- Lump-free mixing

- Special impellor design

- Cleanability

- High due to CIP capability

- Corrosive resistance (e.g. acids)

- Compatible with low viscosity fluids like water/gelatin

- Density/particle size

- Suited for homogenous mixing of low viscosity liquids

- Lump formation risk

- Lump-free operation

- Tank Shape

- Jacketed tank

- Discharge Method

- Gravity / Bottom mounted transfer pump

- Impellor Design

- Special design for lump-free mixing

- Mounting Configuration

- Top of holding tank

- Discharge method

- Gravity / Transfer pump

- Control panel type

- PLC-controlled