Feed Mixing Equipment

Find production technology for mixing feed, and connect directly with leading machine manufacturers worldwide.

In the animal feed industry, nutritionists make the formulas with the available ingredients, depending on the animal to be fed and its production stage. The formulated ingredients are mixed in different processes. However, there is a separate mixing process for the homogenous blending of the ground ingredients (macro and micro) and the liquids that come directly into the feed mixer.

High-quality pellets start with a homogeneous mixing process

Feed mixing equipment is key to obtaining a homogenous blend of the nutrients in the formulations. But apart from producing balanced nutritional values, mixing plays a significant role in the quality of feed pellets.

The ingredients that go into the feed products must be combined uniformly before they are transferred to extrusion and pelleting. Uneven mixing results in pellets of irregular consistency.

Macro ingredients go first in the feed mixing equipment

The sequence of processing in the mixer is critical to achieving an optimal mix, and components must be added in the correct order. The standard rule goes from large to small and from dry to liquids.

Start with the macro ingredients, which are ordinarily pre-ground and blended in the milling process. Then mix in the minor and micro-ingredients such as minerals, vitamins, additives, and premixes. After the mix is achieved, liquids like molasses, amino acids, and fats are ready to be incorporated.

Four parameters to choose the right mixing technology

The quality of the mix must always be uniform and homogenous, meaning that any portion taken from the mixture has to have the same nutritive content as the whole mix. But the quality of the feed mix depends on the type of mixer used.

There are four criteria for selecting a suitable feed mixer: the production capacity, the density of the bulk ingredients, the volume of liquids, and the performance criteria.

Ensure that horizontal mixers are filled to the correct capacity

Horizontal mixers are typically more suited to industrial feed production. And one of the most important factors to consider is capacity.

Overfilling or underfilling the mixer results in incomplete mixing as the agitators need to move the ingredients thoroughly. Keep an eye out for the paddles or ribbons in the mechanism. The feed mix will stay balanced if the design is adequate for your components.

Avoid extreme volumes in vertical mixers to prevent agglomeration

Vertical mixers are more adapted to small-scale plants or on-farm production. These systems leverage gravity to disperse the ingredients uniformly throughout the mix.

However, insufficient mixing time and an excessive production volume compromise the mix’s quality. In the best case, inadequate mixing forms agglomerates or lumps. In the worst case, it could raise the toxicity levels in the feed pellets.

Maintenance tips to follow for a high-quality mixing operation

Proper maintenance of the mixer and all the equipment in the production line is vital for efficient performance and operation.

Preventive maintenance should be done regularly to lubricate, change oil, repair, or replace the moving parts before they are too worn. In everyday operation, the mixer needs to be monitored to control the mixing time and the sequence of adding the ingredients, to check the quality of the mix, and to detect any malfunction on time, guaranteeing a uniform and homogeneously mixed formula.

Which feed mixing technology do you need?

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

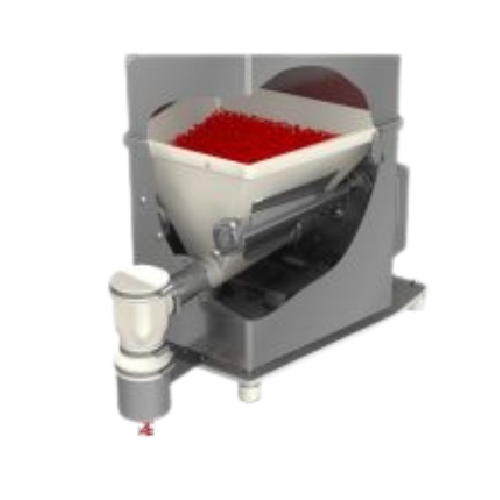

Feeding, dosing, weighing and mixing system for granulate

Achieve precise granulate mixing and rapid color changes with ...

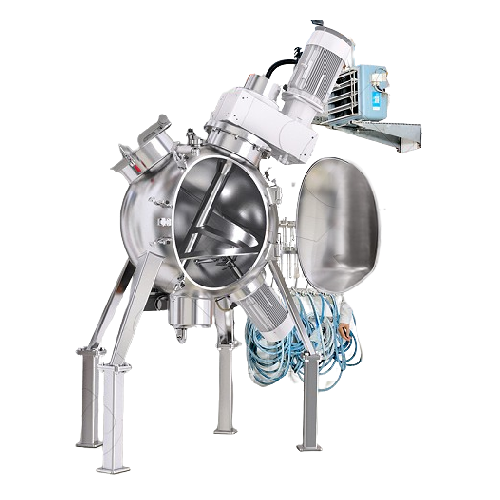

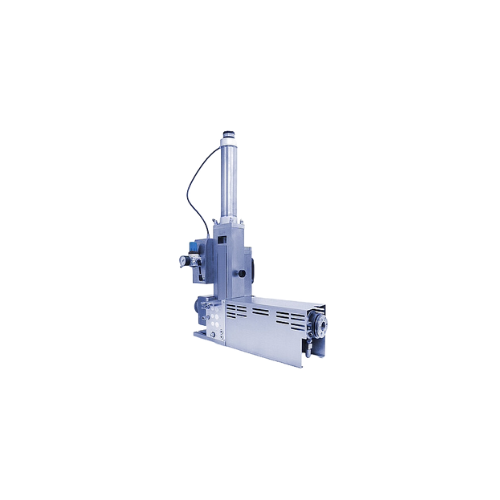

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

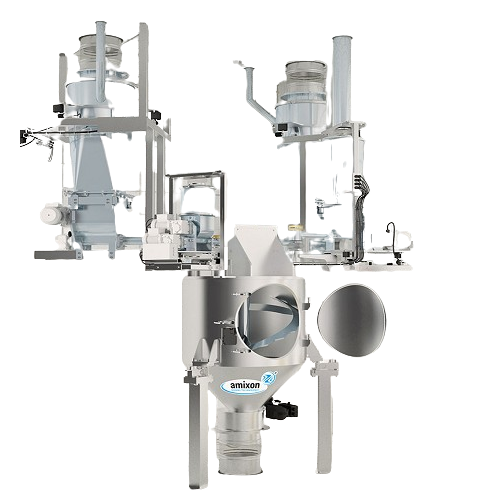

Surge hoppers for efficient batch mixing

Streamline your production with surge hoppers engineered to reduce batch cycle tim...

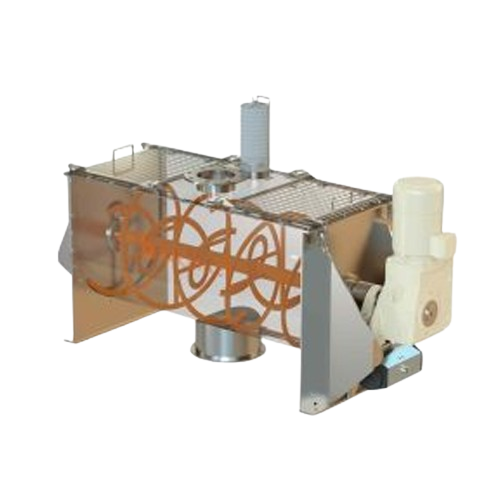

Twin shaft horizontal batch mixers for homogenous material mixing

Achieve consistent and rapid mixing of diverse materi...

Industrial plow mixer for efficient solid and liquid mixing

Experience unparalleled mixing precision with high-speed plo...

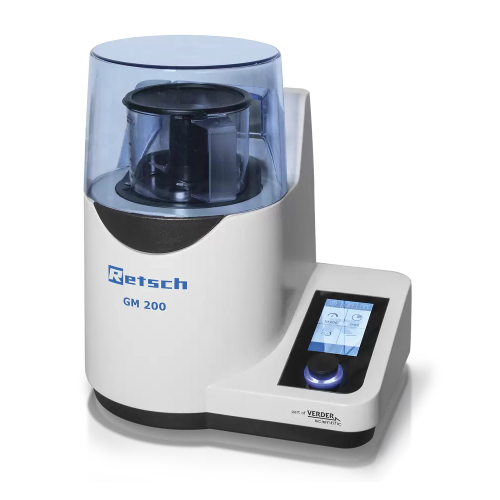

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

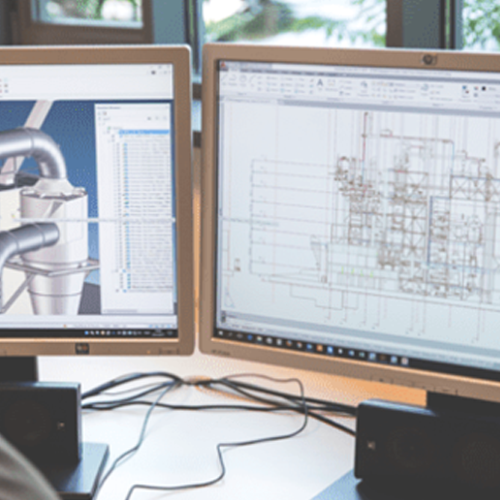

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

Hot start conditioner for feed and food processing

Enhance your production process with a high-efficiency thermal heating...

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Single conditioner for feed mills

Achieve homogeneous mixing and enhanced hygiene in feed production with adjustable paddle...

Laboratory knife mill for fast comminution

Achieve rapid and precise sample preparation with this versatile knife mill, de...

High-shear mixer granulator for pharmaceutical production start-up

Effortlessly achieve optimal granule consistency and...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Industrial wendel mixer for dough production

Optimize your dough and bar production with reduced kneading times and increa...

Hygienic design dough mixer

Achieve superior dough consistency and safety with our hygienic design mixer, ideal for reducing...

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

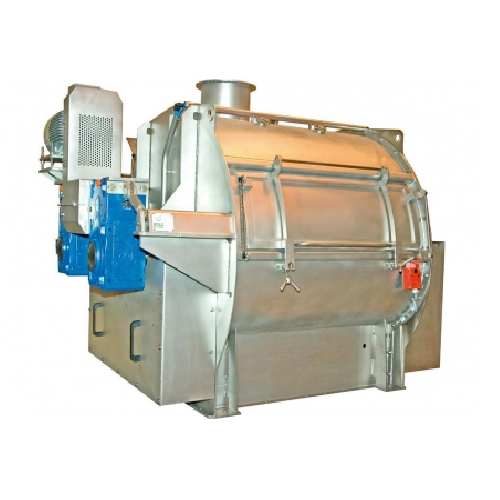

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

R&d mixer for small batch experimentation

Perfect your mixing techniques swiftly with precision-controlled small batch exp...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

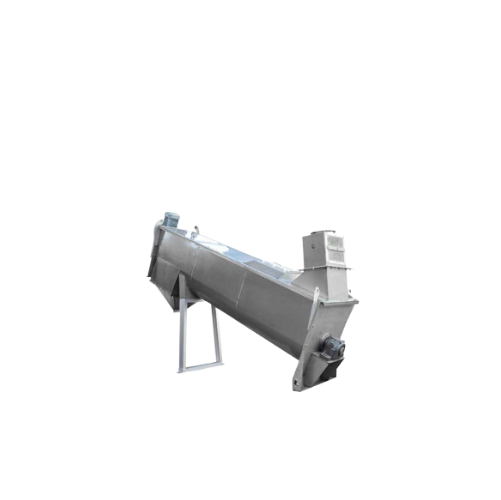

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

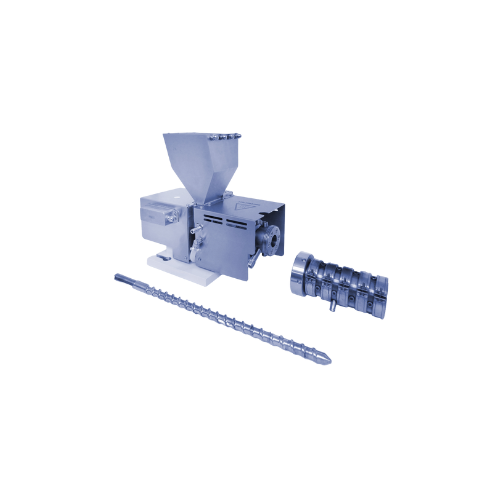

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Mini-compounder for laboratory polymer processing

Streamline your polymer development process with a compact compounding ...

Measuring extruder for small sample simulation

Optimize your production process with this precise extruder, designed to si...

Lab extruder for elastomer extrudability testing

Optimize your small-scale testing with an innovative extruder designed to...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

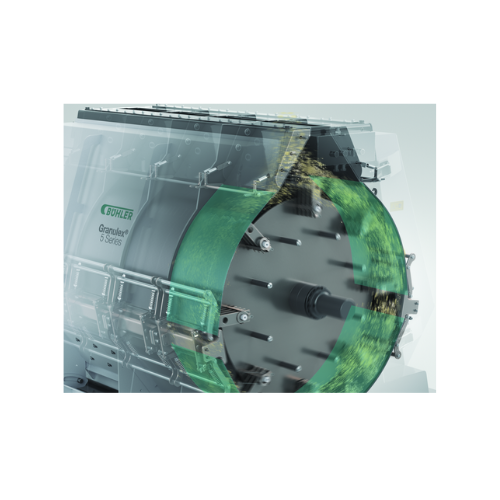

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

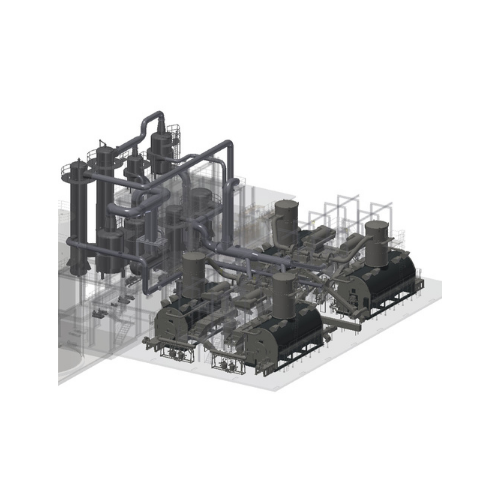

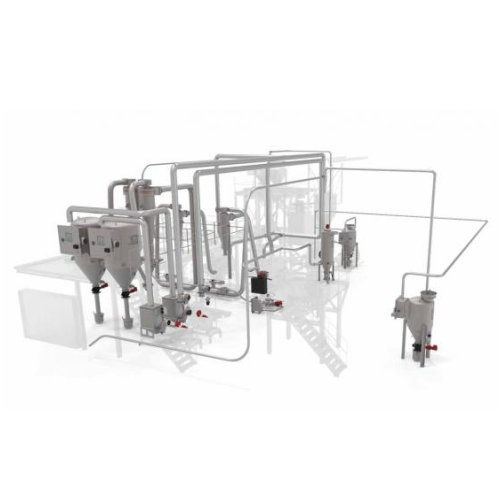

Turnkey plant solutions for industrial applications

Enhance your production line with seamless integration and optimized ...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

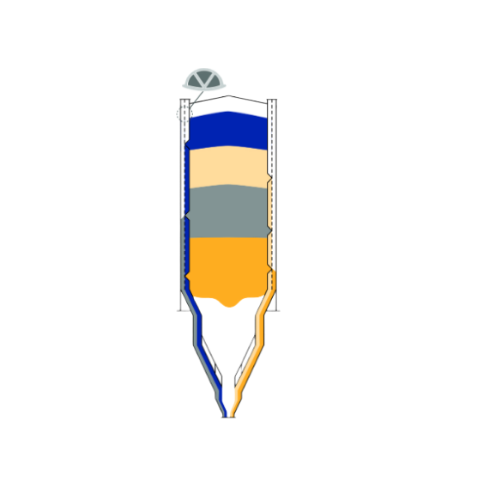

Multi-channel blending silo for free-flowing bulk materials

Achieve precise homogenization and mixing of free-flowing bu...

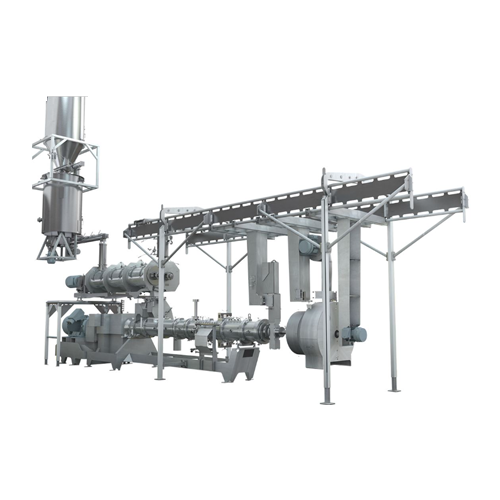

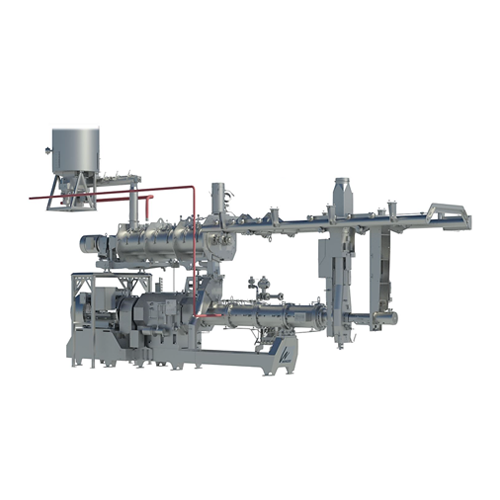

Twin screw extruder for pet and aquatic feed

Achieve exceptional cooking precision with our twin screw extruder, designed ...

Batch-type single shaft mixer for efficient discharging

Optimize your material mixing and discharging processes with a sy...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Continuous single shaft mixer for waste treatment

Achieve consistent mixing homogeneity and prevent dead spots in your pr...

Dust disposal and conditioning system

Optimize your dust management operations with a superior conditioning system designed...

Drying systems for bioethanol production

Optimize your bioethanol production with advanced evaporation and drying equipment...

Automated grain blending system

Achieve precise blending ratios for grains and seeds, streamlining your production line by a...

Blending machine for pre-grinding or tempering processes

Optimize your grain processing with precise blending and mixing ...

Pellet oil coating unit for feed production

Enhance feed pellet nutrition and quality with precise oil, enzyme, and methio...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

Pellet mill conditioner for optimal granulation

Enhance pellet quality and efficiency by seamlessly integrating steam mixi...

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line ...

Single screw loss-in-weight feeder for powders and pellets

Ensure precise dosing and mixing in continuous automated oper...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Scale hopper for industrial batch weighing

Optimize your production line with precise batch weighing and mixing, ensuring ...

Single shaft horizontal batch mixer

Achieve consistent, high-quality blends with precise homogenization using a single shaf...

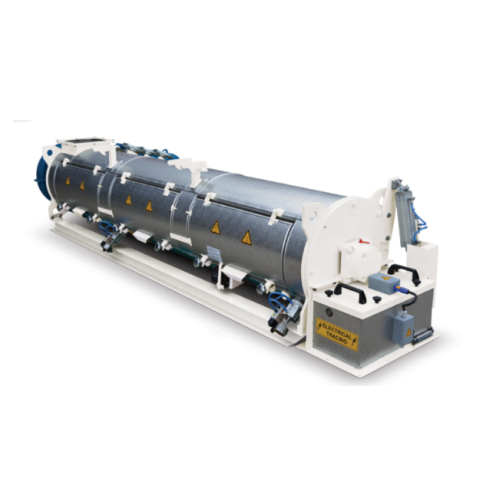

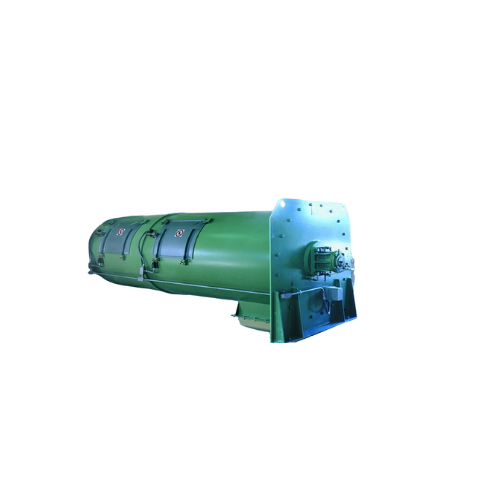

Rotary drum mixer for free-flowing materials

Achieve uniform mixing of heavy, free-flowing solids with precise control and...

Continuous blending system for fragile materials

Ideal for operations requiring gentle handling, this system seamlessly in...

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

Gypsum homogenizer

The quality of gypsum and stucco products is highly influenced by the quality of the calcining process uti...

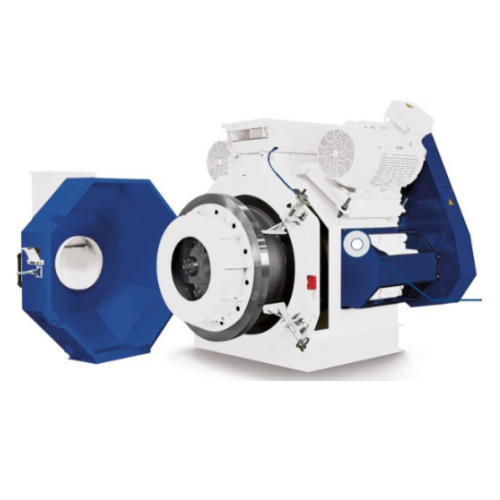

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

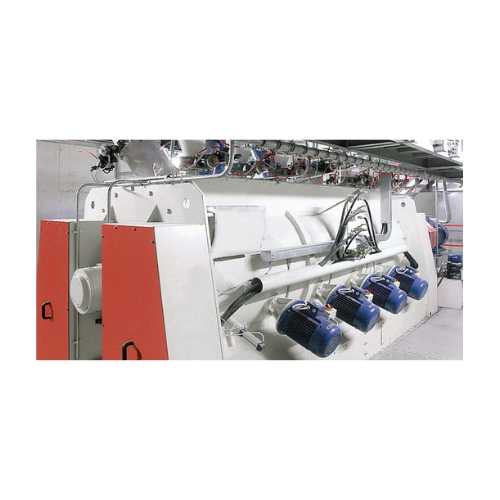

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

Micro-ingredient dosing system for animal feed production

Optimize your feed formulation accuracy with precision dosing,...

Feed expander for improved pellet mill output

Enhance your feed quality and production efficiency with a robust expander d...

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

Granulation line for pharmaceutical manufacturing

Enhance your batch production with integrated mixer and fluid-bed techn...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

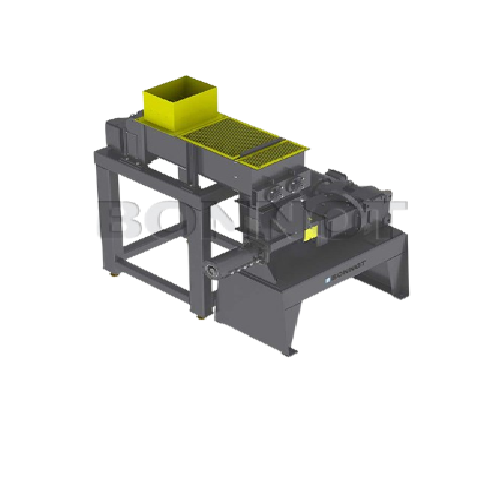

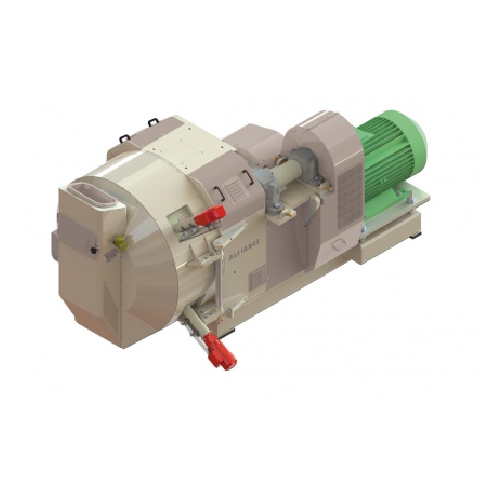

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrat...

Homogenizer for food and feed analysis

Achieve precise homogenization and particle size distribution with this high-speed b...

Single-screw extruder for material analysis

Ideal for material testing and development, this single-screw extruder enhance...

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

Extruder for high-volume pet food production

Maximize production efficiency with an advanced extrusion system designed for...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

Tubular ribbon flight screw feeder for lime feeding

Experience uniform material flow and precise dosing with this special...

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Twin screw feeder for bulk material handling

Optimize your bulk material processing with a solution designed for precise f...

Twin shaft feeder for optimized material feeding

Achieve precise material flow and optimize downstream processing with adv...

Vacuum coater for petfood and livestock feed

Enhance nutritional value and product quality with precision liquid incorpora...

Pre-culture and laboratory systems for microalgae cultivation

Enhance your microalgae cultivation with precise control a...

Dosing screw system for precise ingredient management

Achieve unparalleled precision in formulating mixtures with our dos...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...