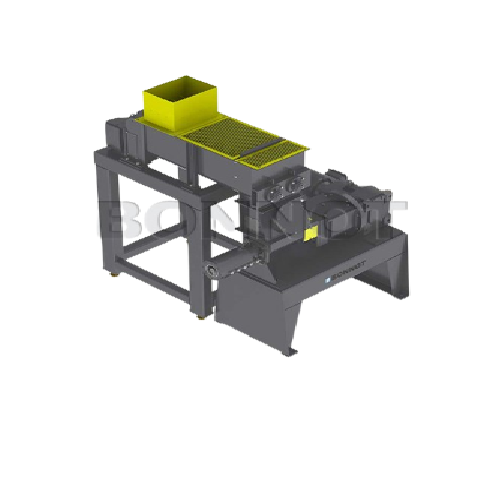

Twin shaft feeder for optimized material feeding

Achieve precise material flow and optimize downstream processing with advanced twin shaft technology, ensuring consistent feed rates and enhanced production efficiency.

Controls Material Feed for Extrusion and Processing

The Twin Shaft Feeders from The Bonnot Company are designed to provide a controlled material feed for extrusion and processing applications. What sets these feeders apart is their variable pitch knives, allowing for customizable residence time and feed rate adjustments, essential for continuous or variable-pitch operations. Ideal for industries such as chemical, food processing, and rubber, they handle a variety of product types including solids, powders, and granules. Typical applications include feeding bulk molding compounds, carbon materials, and rubber extrusions, leading to end-products like molded plastic parts and automotive catalytic converters. The feeders integrate seamlessly into production lines, featuring direct connect gear motors and sealed gear cases for durability, while offering custom bases and orientation to fit existing setups. With processing capabilities tailored through integrated controls, these feeders ensure optimized flow and material consistency, critical for maintaining downstream processing efficiency.

Benefits

- Enhances production efficiency with customizable feed rates for optimal material consistency.

- Reduces downtime through durable construction and easily replaceable components.

- Integrates seamlessly with existing extrusion processes, minimizing footprint and installation time.

- Offers precise temperature management with optional jacketed feed beds.

- Minimizes energy consumption through efficient direct connect gear motor operation.

- Applications

- Cooked foods, Clay, Sealants, Carbon materials, Hydrocolloids, Cold formed products, Rodenticides, Firelogs, Catalysts, Rubber, Bulk molding compounds

- End products

- Molded plastic parts, Automotive catalytic converters, Carbon fiber composite components, Rat poison pellets, Silicone sealants, Gel-based food thickeners, Ceramic tiles, Artificial firewood, Rubber gaskets, Cold-formed steel profiles, Breakfast cereals

- Steps before

- Material Preparation, Mixing, Pre-heating, Testing

- Steps after

- Cooling, Packaging, Quality Control, Final Assembly

- Input ingredients

- bulk molding compound, carbon, catalyst, clay, firelog, food ingredients, hydrocolloid, rubber, sealant

- Output ingredients

- formed extruded materials

- Market info

- The Bonnot Company is known for its expertise in manufacturing industrial extruders and cutting equipment, specializing in engineered-to-order solutions for various industries, including food, chemical, and ceramic sectors, with a reputation for quality and innovation.

- Batch Handling Capacity

- Large

- Knife Pitch Variability

- Variable

- Material Feed Rate

- Adjustable

- Machine Footprint

- Customizable

- Temperature Management

- Jacketed Feed Beds

- Motor Power

- 5 HP - 10 HP

- Shaft Configuration

- Twin Shaft

- Control Type

- Integrated Controls

- Gear Motor

- Direct Connect

- Gear Case

- Sealed

- Hopper Opening Size

- 42" x 16" - 60" x 24"

- Machine Layout

- 55" x 21" x 19" - 79" x 19" x 52"

- Mounting Configuration

- Directly Mounted

- Automation level

- Integrated controls with variable output rate

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Changeover time

- Quick due to bolt through variable pitch knives

- Temperature management

- Jacketed feed beds

- Biological materials

- Yes

- Ceramics

- Yes

- Organic compounds

- Yes

- Polymers

- Yes

- Metal powders

- Yes

- Abrasive materials

- No

- Corrosive resistance

- Yes

- Feed rate

- Variable

- Material Feed

- Controlled

- Feed type

- Customize based on material

- Customization option

- Base and orientation

- Temperature management

- Jacketed feed beds

- Batch handling

- Large

- Operation suitability

- Direct mounting on extruders

- Machine footprint

- 8 Series TF

- Hopper Opening

- 8 Series TF

- Motor Power

- 8 Series TF

- Twin Shafts

- With Variable Pitch Knives

- Customization Options

- Custom bases and orientation

- Gear Case

- Sealed for durability

- Feed Rate Control

- Integrated controls to vary output rate

- Variable pitch knives

- Adjustable

- Custom bases

- Available

- Orientation

- Customizable layout

- Feed bed jacket

- Temperature management

- Integrated controls

- Automatic output rate variation