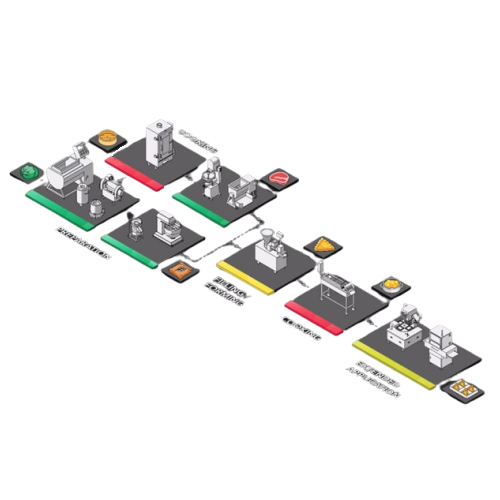

Automatic samosa production system

Optimize your ethnic food production with a machine that seamlessly forms and shapes various samosas, ensuring consistent quality and efficiency in high-volume environments.

Forms and Shapes Samosas Automatically

The ANKO HLT range and SRPF series offer robust solutions for automated samosa production, designed for food manufacturers seeking efficiency in high-volume ethnic and snack food lines. These machines work by integrating dough and filling hoppers, enabling continuous and precise forming and shaping of various samosa types, from vegetable to meat-filled. With adjustable settings for size and filling, they ensure uniformity and quality. Capable of high-speed continuous processing, these machines reduce labor costs and integrate easily into existing production lines. Built with durable materials, they cater to food safety standards and promise ease of cleaning and maintenance. Customizable configurations and engineering support are available to meet specific production requirements.

Benefits

- Streamlines production by automating forming and shaping processes, boosting efficiency.

- Customizable options ensure consistent product quality across various samosa types and sizes.

- Minimizes labor expenses with continuous, high-speed operation.

- Integrates seamlessly into existing production lines for easy adaptation.

- Facilitates adherence to food safety and hygiene standards with easy cleaning and maintenance.

- Applications

- Snack foods, Samosas, World food production, Ethnic foods

- End products

- Cheese samosas, Shrimp samosas, Pork samosas, Spinach samosas, Potato and pea samosas, Beef samosas, Lamb samosas, Lentil samosas, Chicken samosas, Vegetable samosas

- Steps before

- Dough Preparation, Filling Preparation, Dough Rolling

- Steps after

- Samosa Packing, Quality Control, Distribution

- Input ingredients

- samosa dough, filling, prepared dough, prepared filling

- Output ingredients

- high-quality samosas, uniform samosas, perfectly shaped samosas

- Market info

- The Food Machinery Company Ltd. is known for manufacturing bespoke food processing equipment, like conveyors and mixers, offering engineering expertise for industrial-scale food production, backed by a reputation for quality and tailored solutions in the UK and international markets.

- Automation

- Automatic

- Samosa size

- Adjustable

- Wrapper thickness

- Adjustable

- Filling quantity

- Adjustable

- Production capacity

- High

- Hopper type

- Dough and filling hoppers

- Precision

- High

- Uniformity

- Consistent

- Working mechanism

- Automatic forming and filling

- Integrated steps

- Dough and filling combination

- Automation level

- Automatic / PLC-controlled

- Batch vs. continuous operation

- Continuous

- Settings adjustment

- Size, thickness, and filling control

- Output quality control

- Uniform appearance and shape

- User interface

- User-friendly

- Cleaning method

- Manual or semi-automatic

- Energy efficiency

- High efficiency

- Production capacity

- Mass production

- Density/particle size

- 0.5–2.5 g/cm³

- Dough characteristics

- Elasticity, thickness

- Filling consistency

- Uniform, non-porous

- Control panel type

- Touchscreen / Manual

- Control panel type

- Touchscreen / Button-based

- Integration possibilities

- PLC / SCADA system integration

- Adjustable settings

- Samosa size / Wrapper thickness / Filling quantity

- Hopper volume

- Customizable based on production needs

- Production capacity

- Customizable based on the model

- Discharge method

- Customizable options available