Wave-mixed bioreactor for shear-sensitive cell cultures

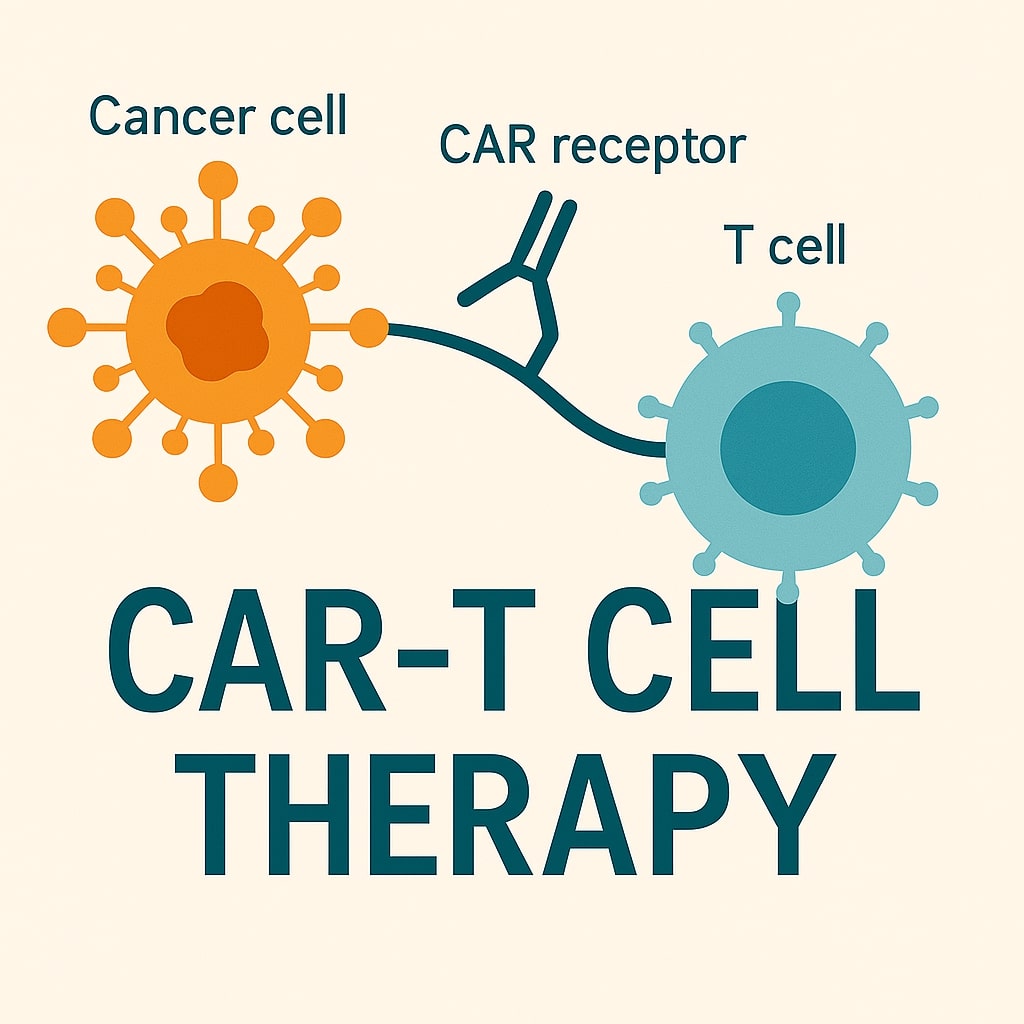

Optimize cell cultivation with a modular, wave-induced mixing system, designed for seamless scaling and precise process control, ensuring conditions ideal for sensitive therapies like CAR-T and stem cell treatments.

Cultivates and Scales Up Cell Therapies

The Biostat® RM from Sartorius is a GMP-compliant, wave-mixed bioreactor that solves key challenges in cell therapy production. This system employs a rocking motion to create an optimal environment for shear-stress-sensitive cell lines, crucial for high-quality yields in products like CAR-T cells and monoclonal antibodies. Ideal for biopharmaceuticals, vaccines, mAbs, and gene therapies, the Biostat® RM integrates seamlessly into your production line with its flexible single-use design.

With a working volume up to 200 liters, it supports scale-up from process development to commercial manufacturing, reducing time and costs associated with expanding production capabilities. Powered by the Biobrain® automation platform, this bioreactor allows for advanced process control with integrated BioPAT® sensors, ensuring consistent operational parameters across all production stages.

Its single-use design minimizes contamination risks and simplifies cleaning processes, while the modular architecture offers configurability to suit varied production scenarios, thus enhancing process intensification. The Biostat® RM meets rigorous industry standards, making it suitable for stringent environments in pharmaceutical and biotech manufacturing.

Benefits

- Enhances cell growth with optimal wave-mixing motion, particularly crucial for shear-sensitive lines.

- Reduces contamination risks with single-use Flexsafe® RM bags, streamlining the validation process.

- Facilitates seamless scale-up from development to manufacturing, saving time and resources.

- Integrates advanced process control through Biobrain® automation, ensuring precise and reliable operations.

- Complies with GMP standards, supporting rigorous pharmaceutical manufacturing environments.

- Applications

- Vaccines, Cell therapy, Regenerative medicine, Biopharmaceuticals, Monoclonal antibodies (mabs), Gene therapy

- End products

- Car-t cell therapies, Allogeneic cell therapies, Autologous cell therapies, Stem cell therapies, Bispecific antibodies, Mrna vaccines, Viral vector-based gene therapies, Influenza vaccines, Monoclonal antibody drugs

- Steps before

- Media Preparation, Cell Culture Expansion, Inoculation, Seed Train Preparation, Process Development

- Steps after

- Harvesting, Purification, Analytical Testing, Storage, Bioprocess Scale-up

- Input ingredients

- CHO cell lines, HEK293 cells, stem cells, CAR-T cells, culture media, flexsafe RM bag, glucose, lactate

- Output ingredients

- cell cultures, monoclonal antibodies, proteins, viruses, bioconjugates, regenerative medicine products

- Market info

- Sartorius AG is renowned for manufacturing high-precision laboratory and bioprocess equipment. They specialize in filtration, fermentation, and cell cultivation systems, known for their innovation and reliability in the pharmaceutical and biotech industries.

- Bioreactor Type

- Wave-mixed, rocking motion

- Automation

- Biobrain® platform

- Working Volume

- 1 L to 100 L

- Capacity

- 2 L to 200 L

- Compliance

- GMP compliant

- Sensor Type

- pH, DO, viable biomass, glucose and lactate

- Bag Type

- Flexsafe®RM

- Tray Size

- 20 L, 50 L, 200 L

- Environmental Conditions

- Control of pressure, temperature, gassing, rocking angle

- Process Intensification

- Seed Train Intensification (N-1 Perfusion), High Cell Density Cell Banking

- Single-Use Technology

- Flexsafe®RM bags

- Working Mechanism

- Rocking motion, wave-mixed

- Automation Level

- Biobrain® automation platform

- CIP/SIP Capability

- Not applicable (single-use bags)

- Batch vs Continuous Operation

- Batch

- Scalability

- 2L to 200L

- Flexibility

- Modular rocker platforms

- Process Control

- Uses BioPAT® sensors

- Parameter Definition

- Advanced with BioPAT® sensors

- Cleaning Method

- Single-use, disposable bags

- Biological compatibility

- Compatible with multiple cell lines including CHO, HEK293, stem cells, CAR-T cells

- Cleanability

- Sterile cultivation chamber with integrated control measurements

- Corrosive resistance (e.g. acids)

- Not Applicable

- Density/particle size

- Not Applicable

- Cell Type Compatibility

- CHO, HEK293, Stem Cells, CAR-T Cells

- Disposable Bag Type

- Basic, Optical, Perfusion

- Machine footprint

- Compact, space-saving design

- Rocker size

- 20 L, 50 L, or 200 L platform

- Bag size (Total Volume)

- 1 L, 2 L, 10 L, 20 L, 50 L, 100 L, 200 L

- Tray size

- 20 L or 50 L tray

- Control panel type

- Biobrain® automation platform

- Working volume range

- 100 ml to 100 L

- Discharge method

- Single-use Flexsafe®RM bags

- Control panel type

- Biobrain® automation platform

- Integration possibilities

- Native connectivity to BioPAT®MFCS4, SCADA, DCS

- Modular design

- Rocker platforms for 20 L, 50 L, and 200 L configurations

- Single-use sensor integration

- pH, DO, glucose, lactate, BioPAT®Viamass

- Bag configuration options

- Basic, Optical, Perfusion configurations

- Automation level

- Flexible process setup with Biobrain®

- Tray size options

- 20 L, 50 L, 200 L

- System scalability

- 2 L to 200 L with only two rocker platforms