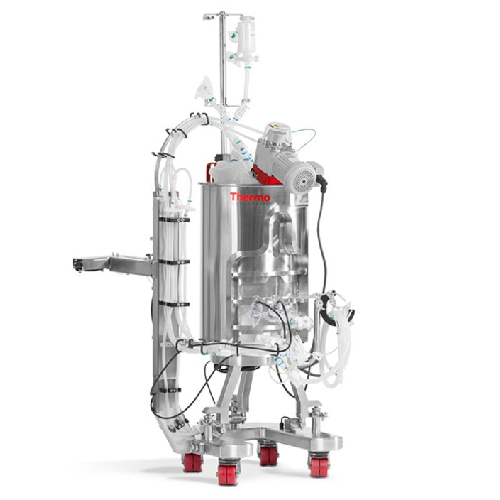

Single-use bioreactor for protein expression

Optimize your biopharmaceutical production with an advanced single-use bioreactor designed to enhance efficiency and scalability in protein expression and cell therapy processes.

Facilitates Mixing and Cultivation in Bioprocessing

The HyPerforma™ 5:1 Single-Use Bioreactor from Thermo Scientific is designed to streamline biopharmaceutical production processes. It employs a unique mixing system to ensure optimal mixing and venting in single-use bioprocess containers (BPCs), enhancing sterility and integrity. Ideal for protein expression, cell, and gene therapy, its applications span monoclonal antibodies, insulin, and vaccine formulations. Available in sizes from 50 to 2,000 liters, it facilitates batch, fed-batch, and perfusion cultures, supporting scalability from pilot-scale to commercial production. Standard features include AC motors for precise agitation control, load cells for monitoring, and options for pH and DO sensors. The jacketed design supports efficient temperature management, while the reduced footprint minimizes hold-up volumes, promoting cost efficiency. Compatible with Finesse™ and Applikon™ control systems, it integrates seamlessly into existing production lines, ensuring compliance with industry standards.

Benefits

- Enhances productivity by supporting a wide range of bioprocessing operations, including batch, fed-batch, and perfusion cultures.

- Minimizes production costs with scalable solutions from pilot to commercial scale.

- Promotes efficient resource use with a compact design and low hold-up volumes.

- Facilitates compliance with industry standards through versatile sensor integration.

- Optimizes operational efficiency with precise agitation and temperature control.

- Applications

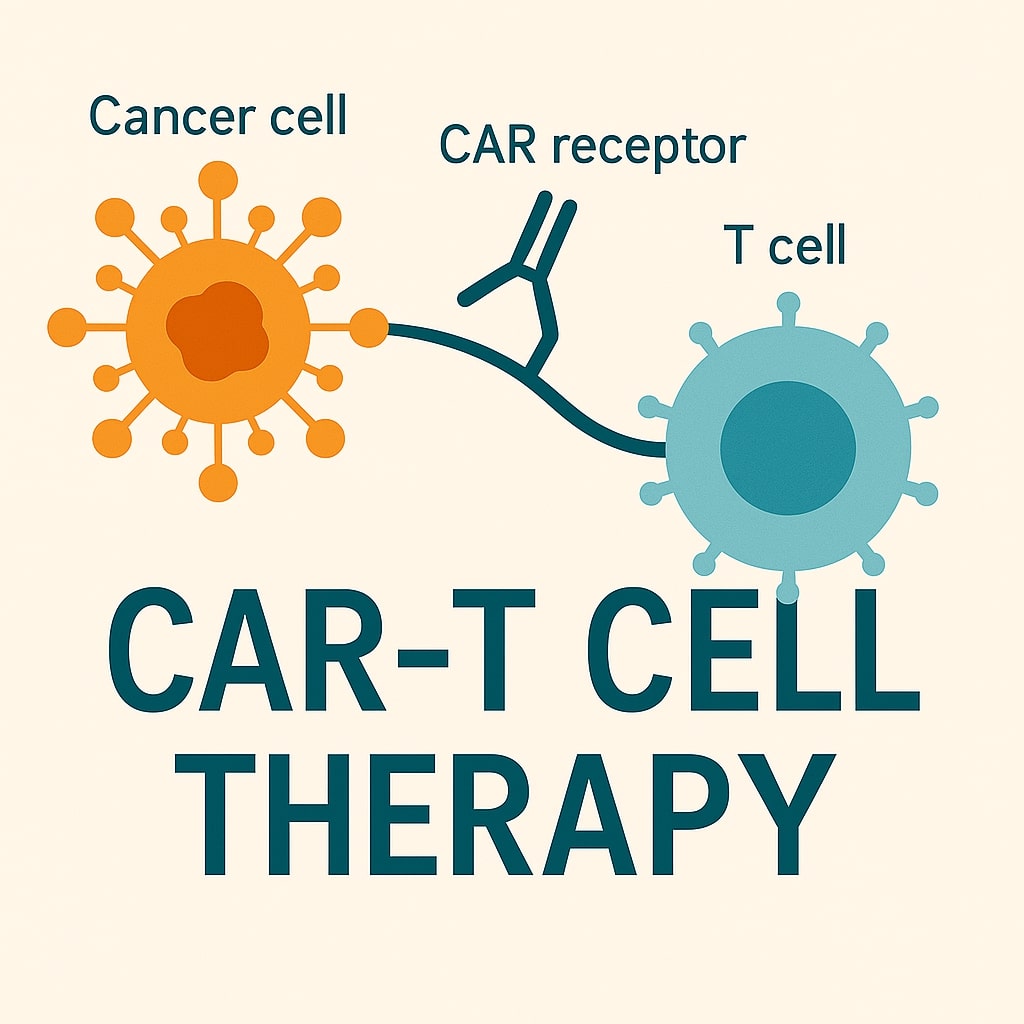

- Liquid formulations, Biopharmaceuticals, Cell and gene therapy, Biofuel, Protein expression

- End products

- Car-t cell therapies, Bioethanol, Insulin, Monoclonal antibodies, Vaccine formulations

- Steps before

- Media preparation, Cell inoculation, System sterilization, Reagent mixing

- Steps after

- Harvesting, Cell separation, Filtration, Downstream processing

- Input ingredients

- cell cultures, suspension cultures, microcarrier cultures, CHO cells, Sp2/0 hybridoma cells, PER.C6 cells, HEK293 cells, Vero cells, MDCK cells, gas for sparging, sterile media

- Output ingredients

- biomass, proteins, cell secretions, CO2 stripped from culture

- Market info

- Thermo Fisher Scientific is renowned for providing innovative scientific instruments, laboratory equipment, and engineered-to-order solutions across various industries, esteemed for their high-quality products and expertise in life sciences, pharmaceuticals, and biotechnology sectors.

- Unit Size

- 50, 100, 250, 500, 1000, 2000 L

- Motor type

- AC motor

- Load cells

- Analog or digital communication options

- Mixing System

- Proprietary overhead mixing

- Sterile contact surfaces

- Single-use

- Temperature sensing

- Included

- Sparger Technology

- Cross-flow sparger technology

- Mixing turn-down ratio

- 5

- Vessel material

- Water-jacketed

- Agitation control

- Precise, with AC or DC motors

- Control systems compatibility

- Finesse™, Applikon™, PC, Delta V™, Allen-Bradley™, Siemens™

- Sensors

- Option to use single-use and traditional sensors for pH, DO, pressure

- Mixing System

- Conventional overhead mixing

- Scalability

- Pilot-scale to commercial production

- Sterility and Integrity

- Single-use sterile contact surfaces

- Control System

- PC, Delta V™, Allen-Bradley™, Siemens™

- Mixing Turn-down Ratio

- 5

- Sparing Technology

- Cross-flow sparger technology

- Application Types

- Batch, fed batch, perfusion cultures

- Motor Type

- AC motor

- Communication Options

- Analog or digital

- Tank Size

- 50 L, 100 L, 250 L, 500 L, 1000 L, 2000 L

- Material

- Stainless Steel

- Mixing System

- Overhead Mixing

- Footprint

- Minimized Vessel Footprint

- Motor Type

- AC Motor

- Temperature Control

- Jacketed

- Sensors

- Single-use and Traditional Sensors for pH, DO, Pressure

- Load Cells

- Analog Load Cells

- Control System Compatibility

- Finesse or Applikon Control Systems

- Cable Management

- Optional Cable Management Tree

- Control panel type

- PC, Delta V™, Allen-Bradley™, Siemens™

- Integration possibilities

- Finesse™ or Applikon™ control systems

- Motor type

- AC or DC motors

- Communication options

- Analog or digital

- Sensor options

- Single-use and traditional sensors for pH, DO, and pressure

- Cable management

- Optional cable management tree