Stainless steel bioreactor for cgmp production

Achieve reliable and scalable production of life-saving medicines with a customizable bioreactor designed for optimal cell and microbial growth, ensuring compliance with stringent cGMP guidelines while enhancing operational flexibility and efficiency.

Cultivates and Ferments Microbial and Cell Cultures

The Applikon BioProduction system from Getinge is a stainless steel bioreactor designed to meet the stringent demands of pharmaceutical and biopharmaceutical manufacturing. This system is engineered for precise control over cultivation and fermentation processes, making it ideal for producing vaccines, monoclonal antibodies, and various biological drugs. It operates using a fully automated Cultivation, Fermentation, and Sterilization process, which includes advanced temperature, pH, and DO2 control systems for optimal microbial and cell culture growth.

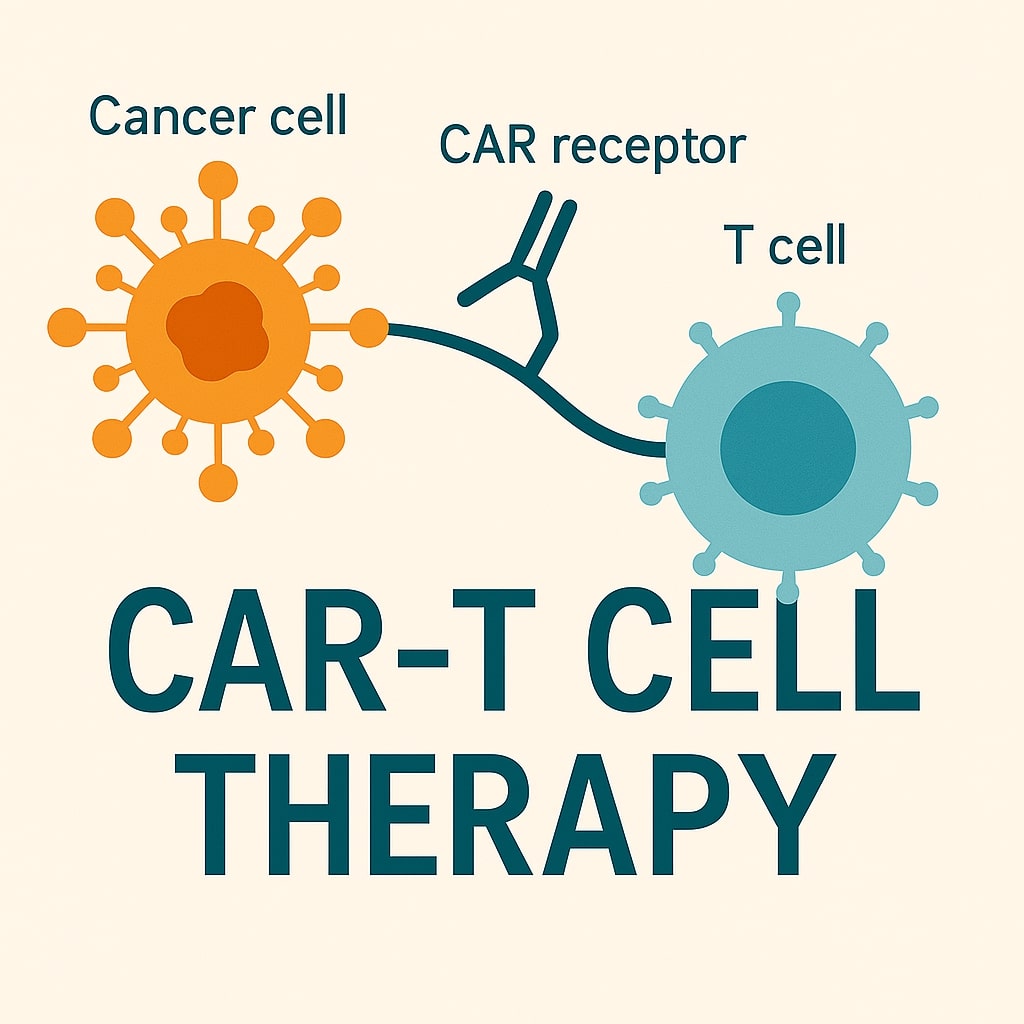

Applications span across pharmaceutical and biotech industries, where it supports the production of insulin, onco-therapeutic vaccines, and CAR-T cell therapies. Offering capacities for both pilot and full-scale production, it can handle volumes up to 5,000 liters. The system integrates seamlessly into existing lines with PLC control options for Siemens and Allen Bradley, providing flexibility in automation and remote monitoring via a DCS.

Energy-efficient design is achieved through its magnetically coupled agitation system, minimizing contamination risks while enhancing mixing efficiency. The bioreactors are fabricated with pharma-grade 316L stainless steel, featuring a surface finish of Ra < 0.4 micron, ensuring superior cleanability and resistance to biofilm buildup. The system is CIP/SIP capable, enhancing its hygiene standards and ease of maintenance. Compliance with cGMP and GAMP guidelines, along with extensive documentation support, facilitates seamless verification and validation protocols. With options for customization to fit specific process needs, including variable gas sparging systems and flexible control architectures, the BioProduction system ensures tailored solutions for any bioprocessing challenge.

Benefits

- Enhances product quality and compliance with comprehensive monitoring and control systems.

- Minimizes contamination risks with sealed magnetically coupled agitation.

- Improves operational efficiency through integrated CIP/SIP systems for quick and thorough cleaning.

- Offers flexible scalability with customizable volumes and configurations to meet diverse production needs.

- Ensures energy efficiency with advanced temperature and agitation control, optimizing resource use.

- Applications

- Microbial cultures, Vaccines, Cell cultures, Biopharmaceuticals, Life-saving medicines, Biological drugs

- End products

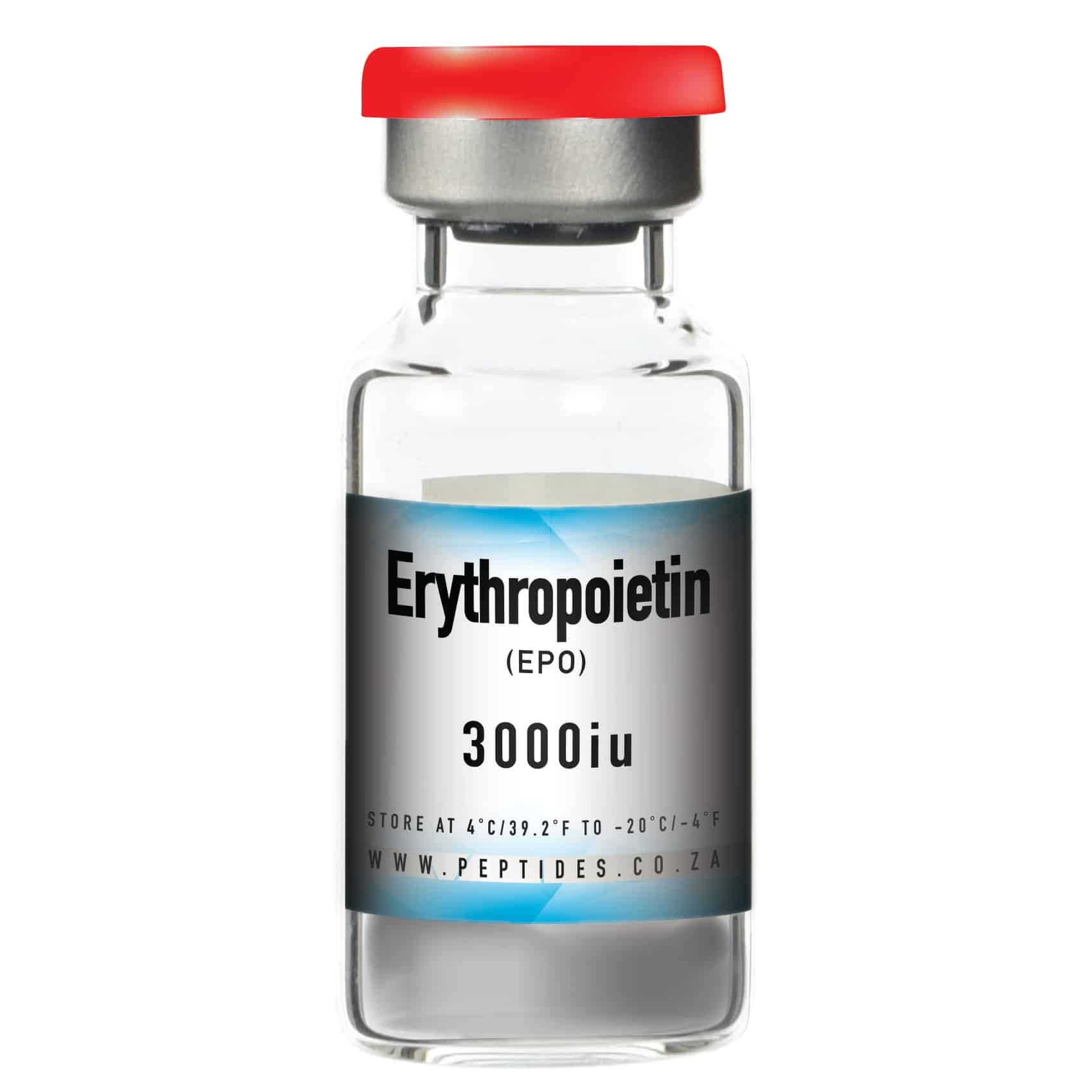

- Onco-therapeutic vaccines, Car-t cell therapies, Erythropoietin, Insulin, Monoclonal antibodies, Cancer immunotherapies, Hepatitis b vaccine, Probiotics

- Steps before

- Media preparation, Sterilization, Buffer preparation

- Steps after

- Harvesting, Inactivation, Sterilization, Packing

- Input ingredients

- microbial organisms, cells, culture media, antifoam agent, CO2 gas, alkali solution, N2 gas, air, O2 gas, tap water, chilled water, indirect steam, direct steam

- Output ingredients

- cultivated cells, microorganisms, fermentation products, exhaust gas, biologics, vaccines, medicines

- Market info

- Getinge is known for providing innovative healthcare and life sciences products, specializing in medical technology, infection control, surgical workflows, and critical care solutions. They maintain a strong reputation for quality and technological advancement in these sectors.

- Total volume

- up to 5, 000 liters

- Drive system

- Magnetically coupled, mechanical seal, bottom or top mounted agitator options

- Maximum agitator tipspeed

- up to 5 m/s

- Impellers

- Rushton, marine, hydrofoil and more

- Gas sparger

- Porous sparger, L-Sparger or Ring-type sparger

- Exhaust gas

- Water cooled exhaust gas condenser with internal spiral and/or jacketed

- Sampling

- Resterilizable sample system

- Manual or fully automated SIP and CIP possible

- Draining

- Resterilizable bottom mounted drain

- Manual or fully automated SIP and CIP possible

- Additions

- Sterilizable additions (push valves) and resterilizable addition ports

- Fully automated SIP and CIP possible

- PH Measurement

- 12 mm classic pH sensor in DN25 port in lower side wall, redundant pH sensor possible

- PH Control

- via acid pump or CO2 gas (rotameter or MFC) in combination with alkali pump

- DO2 Measurement

- 12 mm polarographic DO2 sensor in DN25 port in lower side wall, redundant DO2 sensor possible

- DO2 Control

- via a combination of N2, Air, O2 (Rotameter or MFC) and/or agitation

- Temperature Measurement

- Pt-100 sensor in DN25 port in lower side wall

- Temperature Control

- cooling and heating jacket via bioreactor wall via tap water, chilled water, indirect steam or direct steam injection

- Foam Measurement

- Height adjustable conductivity based foam sensor and/or radar foam detection

- Foam Control

- via antifoam pump, mechanical foam breaker and/or foam centrifuge removal

- Level Measurement

- Height adjustable conductivity based level sensor, radar level detection and/or loadcells under bioreactor (frame)

- Level Control

- pump for liquid addition or removal

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- SIP 135°C / CIP available

- Cleaning method

- CIP / SIP

- Batch vs. continuous operation

- Batch / Fed-Batch / Continuous

- Control system

- PLC-controlled

- Aseptic processing

- Sterilizable-in-Place bioreactor

- Drive system

- Magnetically coupled agitator

- Customization

- Custom volumes and configurations available

- Automation and traceability

- Full automation and traceability

- Cleanability

- Pharma-grade 316L stainless steel

- Corrosive resistance (e.g. acids)

- 316L stainless steel

- Total volume

- Custom built up to 5, 000 liter

- Drive system

- Magnetically coupled, mechanical seal, bottom or top mounted agitator options

- Maximum agitator tipspeed

- up to 5 m/s

- Impellers

- Rushton, marine, hydrofoil and more

- Gas sparger

- Porous sparger, L-Sparger or Ring-type sparger

- Exhaust gas

- Water cooled exhaust gas condenser

- Sampling

- Resterilizable sample system

- Draining

- Resterilizable bottom mounted drain

- Additions

- Sterilizable additions, resterilizable addition ports

- PH sensor

- 12 mm classic, redundant possible

- DO2 sensor

- 12 mm polarographic, redundant possible

- Temperature sensor

- Pt-100 sensor in DN25 port

- Cooling and heating jacket

- Bioreactor wall via tap water, chilled water, indirect steam or direct steam injection

- Foam sensor

- Height adjustable conductivity and/or radar foam detection

- Level sensor

- Height adjustable conductivity based level sensor, radar, and/or loadcells

- Control panel type

- Wide choice of controllers

- Automation configuration

- Complete turnkey system with automation

- Design customization

- Custom volumes, control solutions and materials

- Mounting options

- Skids on wheels or permanent mounts

- Automation system integration

- PLC and DCS options

- CIP/SIP options

- Automated Clean-In-Place

- Manual or automated SIP

- Impeller types

- Rushton, marine, hydrofoil and more

- Gas sparger type

- Porous sparger, L-Sparger, or Ring-type sparger