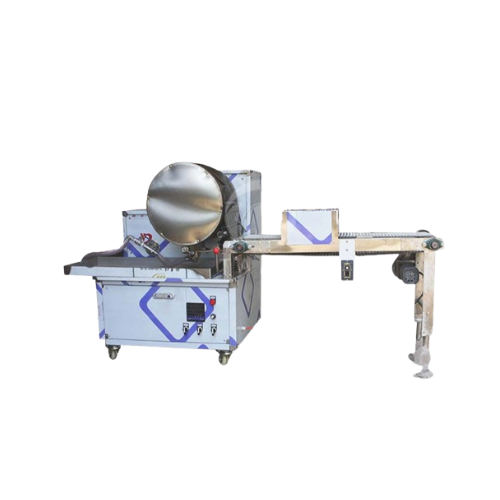

Adjustable spring roll wrapper production system

Efficiently produce uniform spring roll wrappers with customizable thickness and size, ideal for streamlining high-volume food preparation while maintaining consistent quality in every batch.

Produces Spring Roll Wrappers and Pastry Sheets

The TZ series from Zhengzhou Taizy Machinery Co., Ltd. is a versatile solution for producing high-quality spring roll wrappers and pastry sheets. These automatic machines simplify the production process by integrating mixing, pressing, heating, cooling, and forming steps. Capable of producing up to 7,000 pieces per hour, they cater to diverse applications including spring rolls, pancakes, and dumpling wrappers. The machines offer adjustable thickness settings from 0.3mm to 1.2mm to meet specific product requirements. Designed for easy integration into existing production lines, they feature a user-friendly control panel and efficient heat dissipation. Built with stainless steel components, they ensure durability and sanitary operation, complying with food processing standards. Custom mold options further enhance their adaptability, allowing food manufacturers and vendors to meet varied consumer demands efficiently.

Benefits

- Increases production efficiency with high throughput of up to 7,000 pieces per hour.

- Customizable thickness settings enhance product versatility for various market demands.

- Minimizes noise and pollution, ensuring a clean and safe working environment.

- Easy maintenance and cleaning reduce downtime and operational costs.

- Stainless steel construction ensures compliance with food safety standards.

- Applications

- Food wraps, Pastry wraps, Pancakes, Spring rolls, Asian snacks, Egg cakes, Sheet pasta

- End products

- Pastry wrap sheets, Popiah skins, Spring roll sheets, Egg cake layers, Ravioli sheets, Pancake sheets, Lumpia wrappers, Crepes, Tortilla wraps, Spring roll wrappers, Dumpling wrappers

- Steps before

- Flour preparation, Water mixing, Mold selection, Machine setup

- Steps after

- Cooling, Inspection, Packaging, Cleaning

- Input ingredients

- flour, water, dough, stuffing, chicken, shrimp, peanut

- Output ingredients

- spring roll sheet, pancake, egg cake, spring rolls

- Market info

- Taizy Food Machinery is known for manufacturing industrial food processing equipment, specializing in engineered-to-order (ETO) machinery. They have a reputation for innovative, high-quality solutions tailored to meet various customer specifications globally.

- Sheet Thickness

- 0.3-1.2 mm

- Mold Type

- Replaceable

- Heating Method

- Electric / Gas

- Heating Temperature

- Settable

- Production Capacity

- 500-7000 pcs/h

- Machine Dimensions

- Varies with model

- Electric Power

- 6.0KW - 59KW

- Host Power

- 0.75KW

- Belt Power

- 0.18KW - 0.55KW

- Cutter Power

- 0.55KW

- Sheet Size

- 180mm - 500mm (round)

- 200mm - 520mm (rectangular)

- Forming Method

- Hydraulic press

- Working mechanism

- Flour-water dough pressing and heating

- Integrated steps

- Dough mixing, pressing, baking

- Automation level

- PLC controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick, mold replacement capability

- CIP/SIP

- Manual cleaning required

- Cleaning method

- Movable door for easy maintenance

- Energy efficiency

- High, with temperature control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Spring roll diameter

- 180mm/280mm/430mm/500mm

- Compact footprint

- 4.3*0.8*1.35m to 6.2*1.15*2m

- Control panel type

- Control cabinet

- Machine weight

- 320kg to 1200kg

- Sheet thickness

- 0.3-1.2mm

- Sheet size (Max.)

- 180mm to 500mm round, 200mm to 520mm rectangular

- Frame Material

- Not specified

- Heating cylinder diameter

- 360mm to 1200mm

- Movable door

- Yes

- Heating elements

- Adjustable

- Thickness adjustment

- 0.3-1.2mm

- Diameter customization

- 180mm round

- Mould replacement

- Varied thickness and shapes