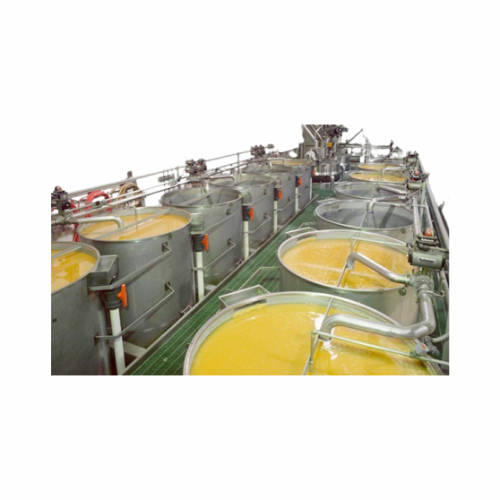

Corn soak tank for tortilla and corn chip processing

Achieve optimal moisture and texture in corn products with a custom-designed soak tank system, enhancing the soaking process for improved milling efficiency and product quality.

Soaks and Moisture-Conditions Corn for Snack Production

The Corn Soak Tank System from Heat and Control is engineered for food manufacturers and snack food companies seeking precise moisture control in corn-based products. Designed for tortilla and corn chip production, this system efficiently soaks and pumps corn, preparing it for milling or further processing. The tanks are constructed from durable stainless steel, featuring smooth internal seams and cone bottoms for complete draining, minimizing downtime. With options for manual, semi-automatic, or fully automated operation via a programmable controller, the system integrates seamlessly into existing production lines, providing reliable and accurate soak cycles. Suitable for processing both solid and liquid forms, it enables high throughput, customizable to your specific process requirements. The system complements equipment like corn cooking systems and horizontal motion conveyors, allowing scalability in corn processing applications. Experience reduced energy consumption and simplified maintenance with easy-access CIP systems, supported by Heat and Control’s extensive engineering and after-sales support.

Benefits

- Enhances product consistency with precise moisture control for corn-based foods.

- Reduces floor space requirements with elevated, customizable tank configurations.

- Minimizes labor involvement through flexible automation options, from semi-automatic to fully automated systems.

- Decreases production downtime with efficient draining and cleaning capabilities.

- Integrates seamlessly with existing corn processing equipment, streamlining operations.

- Applications

- Tostadas, Formed shells, Tortillas, Tortilla chips, Corn chips, Taco shells

- End products

- Frito corn chips, Taco bell taco shells, Baked tostadas, Mission flour tortillas, Corn tortilla chips

- Steps before

- Corn Cooking, Simmering

- Steps after

- Milling, Corn Chips Production, Taco and Formed Shells Production, Tostadas Production, Tortillas Production

- Input ingredients

- corn, dry corn, raw corn

- Output ingredients

- corn with desired moisture content, texture for milling, prepared masa, corn products like tortilla chips, corn chips, taco shells, tostadas, tortillas

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Material

- Stainless steel

- Construction Type

- Durable and efficient

- Tank Design

- Cone bottoms for fast draining

- Platform Type

- Stationary, elevated

- System Automation

- Manual, Semi-automatic, Fully automated

- Pump Type

- Gentle pumping system

- Capacity Options

- Roll-around tanks available

- Control System

- Programmable controller systems

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / Semi-automatic / Fully automated

- Cleaning method

- CIP / Manual

- Cleanability

- Yes, smooth internal seams

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Hull Loosening

- Effective

- Tank shape

- Cone bottom

- Material

- Stainless steel

- Footprint

- Stationary, elevated platform

- Drainage

- Complete draining

- Mobility

- Roll-around tanks available

- Internal seams

- Smooth

- Control panel type

- Manual / Semi-automatic / Fully automated programmable controller

- Platform design

- Custom-fit, stationary, elevated platform

- Material construction

- Stainless steel with smooth internal seams and cone bottoms

- Tank mobility

- Roll-around tanks available