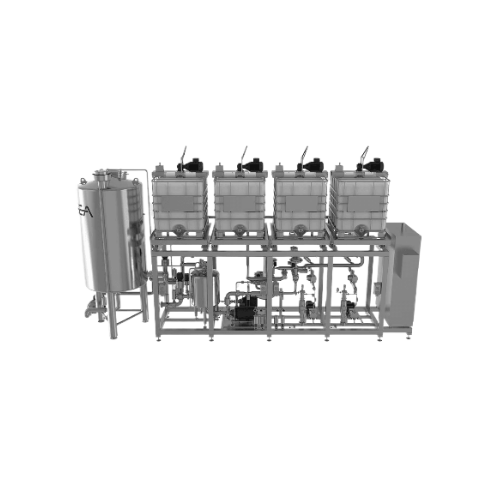

Continuous in-line blender for beverage industry

Enhance your blending precision and process flexibility with a system designed to optimize component ratios directly in-line, ensuring continuous, homogenous mixing and seamless integration into your production line.

Mixes and Monitors Multi-Component Liquid Blends

The GEA DICON® Continuous In-line Blending System revolutionizes beverage manufacturing by providing precise, continuous mixing of liquid components directly in the pipeline. This system excels in blending various ingredients for non-alcoholic and alcoholic beverages, including tonic water and ready-to-drink cocktails. Utilizing high-accuracy flow meters, it ensures exact component ratios and homogeneously mixed outputs, vital for maintaining product consistency. With its automated, PLC-integrated setup, the DICON® system streamlines operations, allowing for real-time monitoring and correction of key parameters like Brix value and conductivity. Its compact, factory-tested design is ready for seamless integration into existing production lines, requiring no additional mixing tanks. The system’s energy efficiency is enhanced by unique GEA control algorithms, while compliance with industry standards supports reliable performance across diverse applications. Additionally, the unit is equipped with modulating valves and positive pumps to ensure precise flow control, with customization options available to meet specific process requirements.

Benefits

- Ensures consistent product quality by maintaining precise mixing ratios through real-time monitoring.

- Reduces resource use with direct pipeline mixing, eliminating the need for additional mixing tanks.

- Enhances production efficiency with automated in-line adjustments and corrections.

- Saves energy and reduces operational costs through optimized flow control algorithms.

- Seamlessly integrates into existing systems, minimizing installation time and disruption.

- Applications

- Beverages, Syrup, Carbonated soft drinks, Alcoholic beverages, Non-alcoholic beverages

- End products

- Distilled vodka, Tonic water, Alcohol-infused seltzers, Ready-to-drink cocktails, Lemon-lime soda, Carbonated cola, Ginger ale, Energy drink syrup, Fruit punch syrup, Blended whiskey

- Steps before

- Alcohol reception, Raw ingredient reception, Ingredient measurement

- Steps after

- Carbonation, Quality control, Product transfer, Packaging

- Input ingredients

- soft drink components, syrup, raw alcohol, water

- Output ingredients

- homogeneous soft drinks, blended syrup, alcohol-water mixture

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Accuracy

- High accuracy with precise flow meters

- Flow rate

- Upwards of 1 l/h in concentrate lines

- Automation

- Automatic system controller

- Mixing method

- Direct mixing in pipeline

- Component control

- Precise ratio measurement and control

- In-line analysis

- Continuous in-line quality analyses

- Monitoring

- Cyclical monitoring of flow meters

- Control deviation compensation

- Short-term deviations completely compensated

- Valve and pump control

- Modulating valves and/or positive pumps with frequency converter

- Air elimination

- Deaerating vessels prevent air occlusions

- Correction capability

- Automatic correction of Brix deviations

- Alcohol content control

- ±0.05% volume of alcohol

- Density metering system

- Regulatory-compliant

- Device readiness

- Compact, factory-tested, ready for connection

- Working mechanism

- Continuous in-line blending

- Automation level

- Automated digital controller

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Quick availability of product

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact, factory-tested device, ready for connection

- Piping system

- Direct mixing of the products in the pipeline

- Discharge method

- In-line blending

- Control panel type

- Digital controller

- Flow meter accuracy

- High accuracy

- Control System Type

- Digital controller

- Flow Meter Type

- High-precision flow meters

- Integration Possibilities

- Can be combined with GEA DICAR carbonator

- Blending System Type

- In-line continuous blending system

- Control Algorithms

- Unique GEA control algorithms

- Density Metering System

- Regulatory-compliant

- Control Unit Placement

- Outside hazardous area

- Operation Interface

- User-friendly