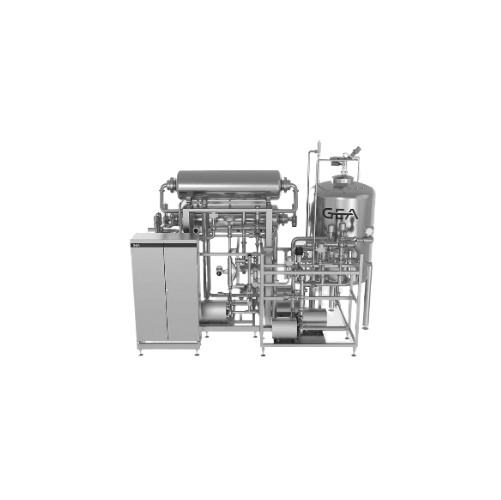

Mixer and carbonator for soft drinks

Achieve precision in continuous mixing and carbonation, ensuring perfect beverage consistency with optimal CO2 integration for a balanced taste and enhanced shelf life.

Mixes, Carbonates, and Deaerates Soft Drinks

The GEA DIMIX-C from GEA Group is an engineered-to-order solution designed for the continuous mixing and carbonation of beverages such as cola, lemon-lime soda, and flavored mineral water. This system integrates three dedicated modules: the GEA DIOX-2 for precise water deaeration, the GEA DICON®-C for in-line blending, and the GEA DICAR-C for accurate beverage carbonation. Key features include vacuum spray technology for effective oxygen removal, ensuring longer shelf life and improved taste, and high-precision flow meters for consistent ingredient blending. The system operates continuously, with automatic brix compensation, enhancing product uniformity during production changes. The integrated Venturi saturator ensures fine CO2 dispersion, maintaining the desired carbonation level without losses. Built to streamline beverage operations, the DIMIX-C offers substantial energy savings, and its versatility accommodates still and carbonated products, complying with industry standards for hygiene and efficiency.

Benefits

- Enhances product quality with precise carbonation and blending.

- Extends shelf life by effectively reducing oxygen levels in beverages.

- Optimizes resource use, reducing CO2 losses in continuous operations.

- Saves energy through efficient, automated control systems.

- Facilitates quick cleaning cycles with integrated CIP capabilities.

- Applications

- Beverages, Carbonated drinks, Non-alcoholic beverages, Soft drinks, Juice industry

- End products

- Orange soda, Tonic water, Diet soft drinks, Lemon-lime soda, Cola beverages, Sparkling water, Energy drinks, Sports drinks, Carbonated fruit juices, Flavored mineral water, Sweetened iced tea

- Steps before

- Water purification, Syrup preparation, Liquid component measurement

- Steps after

- Filling, Bottling, Packaging

- Input ingredients

- product water, CO2, syrup, liquid components, final syrup, premix

- Output ingredients

- carbonated soft drinks, still products, carbonated beverages, fine-sparkling beverage

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Deaeration Efficiency

- ≤0.05 mg O2/l

- Automation

- Fully Automated

- CO2 Dispersion

- Fine distribution

- Blending Accuracy

- High-precision

- CO2 Saturation

- Venturi saturator system

- Blending Process

- Continuous in-line

- Brix Measurement

- Automatic compensation

- Operational Mode

- Continuous

- Working mechanism

- Continuous inline mixing and carbonation

- Integrated steps

- Water deaeration, in-line blending, carbonation

- CIP principles

- Efficient, cost-saving CIP with premix stream

- Automation level

- Digital controller with GEA control algorithms

- Batch vs. continuous operation

- Continuous

- CO2 management

- No CO2 losses during carbonation

- Flexibility

- Produce still and carbonated products

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Control panel type

- Digital

- Discharge method

- Inline continuous

- Control panel type

- PLC with HMI

- Integration possibilities

- SCADA System Integration

- Recipe management system

- Yes

- Compact footprint

- Yes