Sensor potting solution

Ensure precise protection for your electronic components with this flexible potting solution, designed to handle diverse challenges while maintaining material integrity to withstand external influences such as heat, moisture, and vibration.

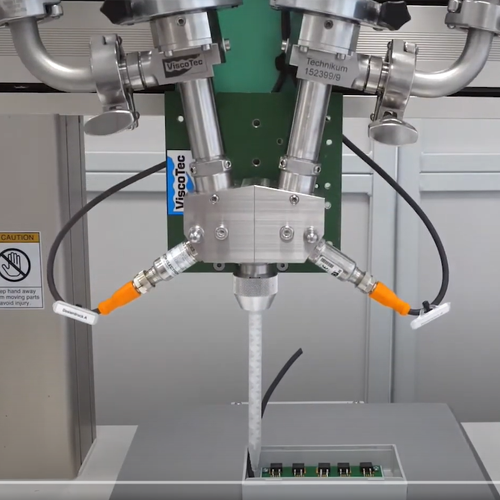

Dispenses and Pots Sensors Accurately

The ViscoDuo-VM from ViscoTec is a dual-component dispensing system specifically designed for sensor potting applications. Utilizing endless piston technology, it offers precision and flexibility in both small and large volume dispensing, ensuring material homogeneity and optimal potting depth through its two-stage process. Ideal for integrating into automated lines, it supports both manual and robotic operations, enhancing production efficiency with features like programmable suck-back to prevent contamination. The ViscoDuo-VM accommodates a wide variety of applications, from optoelectronics to automotive components, and is perfect for protecting sensitive electronics with varied potting materials, such as silicones and epoxies. Its robust design, including options for degassing and material recirculation, allows for high-throughput operations while maintaining quality and consistency.

Benefits

- Enhances product reliability through precise and homogenous potting.

- Supports flexible production with both manual and automated operations.

- Minimizes waste and contamination risks with programmable suck-back.

- Reduces cycle time with integrated multi-component mixing and dispensing.

- Maintains uniform material quality with efficient recirculation and agitation features.

- Applications

- Temperature sensors, Engine ignition sensors, Automotive components, Optoelectronics, Sensors, Fork photoelectric sensors, Electronics, Headlamp potting

- End products

- Temperature sensor tubes, Photoelectric sensors, Automotive headlamps, Diesel engine ignition sensors

- Steps before

- Material preparation, Material degassing, Material agitation

- Steps after

- Curing, Quality inspection, Assembly

- Input ingredients

- potting materials, one or two-component materials, silica gel filter, thermal paste, 3-component materials, 2-component epoxy resin, water-repellent agent, 2-component silicone

- Output ingredients

- potted sensors, embedded temperature sensors, potted electronics, potted headlamps

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Accuracy

- High precision

- Automation

- Manual / Automatic

- Dosing type

- 1-component / 2-component

- Mixing Ratio

- Varies per application

- Dispensing Speed

- Adjustable

- Control System

- PLC

- Material Compatibility

- Handles viscous and non-viscous materials

- Temperature Control

- Maintains fill level precision

- Fill Level Detection

- Triangulation laser sensor

- Suck-back Feature

- Programmable

- Working mechanism

- Endless piston technology

- Automation level

- Manual / Automated with PLC integration

- Batch vs. continuous operation

- Continuous dispensing

- Material recirculation

- Present

- Integrated steps

- Two-stage potting process

- Dispensing control

- Analog via PLC

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compatibility with potting compounds

- 1-component, 2-component, 3-component materials

- Machine footprint

- Compact/Variable depending on system

- Tank Shape and Size

- ViscoTreat-R storage tank with agitator

- Feed method

- Recirculation for material homogeneity

- Discharge method

- 2-component dispenser for potting

- Control panel type

- Analogue control via main PLC

- Automation level

- Manual/Automatic dispensing

- Palletizer Integration

- Yes, for fully automatic production

- Dispensing flexibility

- Can handle both large quantities and small dots

- Programmable suck-back feature

- Yes, to prevent contamination

- Control panel type

- PLC / HMI

- Integration possibilities

- Manual / Automatic / Robot-assisted

- Flexibility

- Manual and automatic

- Palletizer integration

- Possible

- Suck-back functionality

- Programmable

- Analog control

- 0 to 10 V / 4 to 20 mA