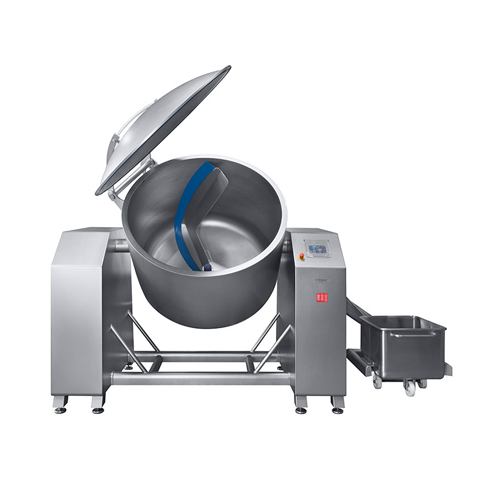

Energy-saving cooling tumbler for meat, poultry, and fish processing

Enhance your meat, poultry, and fish processing with a cooling tumbler that optimizes marinating and massaging, ensuring even flavor distribution and improved texture while reducing energy consumption.

Cools and Massages Meat, Poultry, and Fish

The ESK 1200–1500 STL-B from VAKONA GmbH is a versatile cooling tumbler designed for seamless integration in meat, poultry, and fish processing lines. This equipment uses a direct cooling system with a powerful cooling aggregate and heat exchanger, ensuring optimal temperature control during massing, mixing, massaging, marinating, and tumbling processes. Its vacuum system features a high-performance pump and programmable aeration cycles to enhance product quality. Ideal for a range of end-products like marinated chicken breasts and smoked salmon, it accommodates substantial batch sizes with its broad capacity range. The touch screen control unit offers both automatic and manual operation, with memory for up to 99 customizable recipes. Built with stainless steel for durability and hygiene, it includes a self-cleaning vacuum system and electrical lid operation for ease of maintenance. With an emphasis on energy efficiency, its design provides reduced operational costs, while a slew of optional equipment allows for tailored solutions to specific processing needs.

Benefits

- Enhances product texture and flavor by integrating precise cooling and vacuum control.

- Reduces energy costs through an efficient direct cooling system.

- Increases operational flexibility with customizable processing parameters for diverse recipes.

- Simplifies maintenance and cleaning with automated features and easy-access design.

- Supports large batch processing, optimizing productivity and throughput.

- Applications

- Marinades, Meat, Poultry, Fish

- End products

- Honey mustard chicken wings, Beef jerky, Turkey cold cuts, Teriyaki beef strips, Pepperoni slices, Marinated chicken breasts, Lemon herb fish fillets, Smoked salmon

- Steps before

- Slicing, Pre-marinating, Brine injection

- Steps after

- Packaging, Freezing, Cooking

- Input ingredients

- meat, poultry, fish, meat products, poultry products, fish products, marinades, ingredients for massaging, ingredients for marinating, ingredients for tumbling

- Output ingredients

- massaged meat, mixed poultry, marinated fish, tumbled meat, processed poultry products, processed fish products

- Market info

- Vakona Germany is known for manufacturing engineered-to-order industrial equipment, specializing in high-quality machines for food processing, particularly marinating and tumbling equipment, with a strong reputation for reliability and innovation in the market.

- Bowl volume

- 1200–1500 L

- Capacity

- 100–1150 kg

- Rotation speed

- 3–18 rpm

- Electrical supply

- 3-N-PE, 400 V, 50 Hz, 16 A

- Recipe memory

- 99 recipes

- Cooling system

- Direct cooling with heat exchanger

- Temperature control

- Adjustable

- Vacuum system

- High performance vacuum pump

- Tilt mechanism

- Electrical tilting

- Automation level

- Manual / Automatic

- Batch vs. continuous operation

- Batch

- Cleaning method

- Easy Cleaning

- Energy efficiency

- Energy saving

- Memory capacity

- Up to 99 recipes

- Operation type

- Manual / Automatic

- Temperature control

- Adjustable

- Vacuum control

- Automatic and programmable

- Tilting mechanism

- Electrical

- User friendliness

- High

- Abrasion resistance

- Stainless steel components

- Biological compatibility

- Food-grade materials

- Cleanability

- Easy cleaning design

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Machine footprint

- Customizable

- Bowl volume

- 1200–1500 L

- Tumbling arm rotation speed

- 3–18 rpm

- Stainless steel construction

- Yes

- Direct cooling system

- Yes

- Vacuum system

- Yes

- Electrical tilting mechanism

- Yes

- Touch screen control

- Yes

- Machine stationary

- Yes

- Machine cabinet and frame material

- Stainless steel

- Electrical lid operation

- Yes

- Control panel type

- Touch screen control unit

- Integration possibilities

- Automatic and manual operation modes

- Recipe memory

- Up to 99 recipes

- Tumbling arm speed

- Variable adjustable from 3-18 rpm

- Bowl adjustment

- Electrical, infinitely variable tilting

- Lid operation

- Electrical