Making Dishwasher Tablets

Find innovative production technology for making dishwasher tablets and connect directly with world-leading specialists

A dishwasher tablet is an essential detergent. It consists of a pressed mixture of sodium and potassium salts, surfactant, fragrance, and other filler agents, mixed with the help of tablet making machines. The products’ use in America and Europe is high, unlike in the Asian continent, where the price limits its usage. Its global market size will reach $990 million in 2026 from $475.6million in 2019, according to Grand View Research forecasts.

Select your dishwasher tablets process

Tell us about your production challenge

Dishwasher tablet equipment and ingredients

The key process in making a dishwasher tablet involves combining specific quantities of the key ingredients in the dishwasher tablet machine to achieve the desired properties. Examples of these components are surfactants, that aid the cleaning property of the detergent, and sodium, which provides stability.

Producers start the dishwasher tablet manufacturing process by obtaining granular detergent additives from a spray-dried slurry. They use a mixer to combine the granules with builders, water, surfactant, bleaching agent, dye, and fragrance. Lastly, they transfer it to a hydraulic or automatic rotary tablet press for the tableting process.

The key process of making a multilayer detergent tablet

Dishwasher tablets can either come in a single layer or multilayer thickness. A multilayer detergent tablet for dishwashing machines comprises a first cold-water-soluble layer of alkali metal metasilicate nonahydrate, penta-alkali metal triphosphate, and a low-foaming non-ionic surfactant; and a second layer which dissolves rapidly at increasing water temperatures comprising alkali metal metasilicate, penta-alkali metal triphosphate, and an active chlorine compound.

These layers are weighed and appropriately measured to guarantee their release at different stages of the dishwashing process. To ensure the layers don’t separate, manufacturers ensure they are adequately pressed. Tablet thickness is a crucial step in manufacturing this product.

Factors that define a good dishwasher tablet

Combining the appropriate ratio of key ingredients in the production process is the initial step towards achieving a high quality dishwasher tablet. The product should have a broad dissolving profile. In this case, 10-40% by weight should dissolve in the cold water pre-rinse cycle while 60-90% remains available for the dishwashing cycle.

The product must clean the items without leaving residues. Surfactants improve their ability to clean by enhancing the separation of food remains. Builders like silicate prevent the formation of lime coatings and improve the function of surfactants. They do it by removing calcium or magnesium ions from water and food particles.

Their typical alkali-reacting components should provide an ideal pH of at least 10.0 in the wash liquor.

Are dishwasher tablets safe?

The environmental impact of dishwater tablets is negative mainly because they contain high phosphate levels. Even though phosphates provide stability to dishwasher tablets and make them more efficient by binding to calcium and magnesium ions, they are undesirable. They remain in wastewater and eventually sip into a natural body of water, promoting algae growth.

To make commercially available phosphate-free products requires tabletting powder mixtures containing anhydrous Sodium metasilicate in addition to Sodium metasilicate nonahydrate.

Combining water-containing substances and substances capable of absorbing water increases the product’s resistance to breakage in the pre-rinse cycle.

Processing steps involved in dishwasher tablets making

Which dishwasher tablets technology do you need?

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

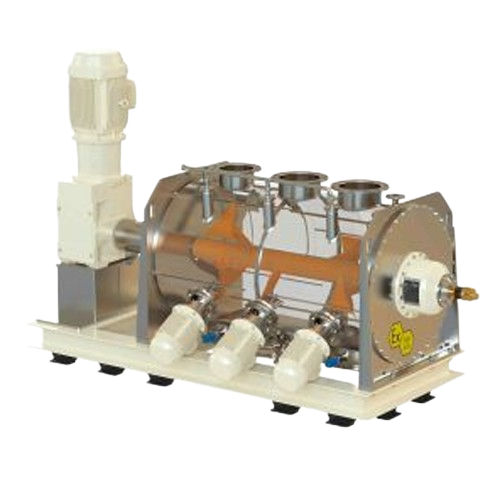

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

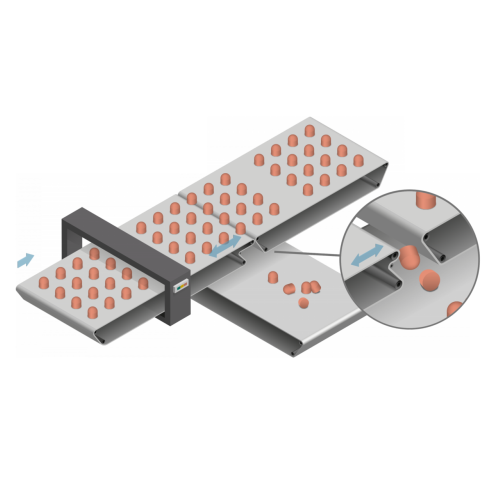

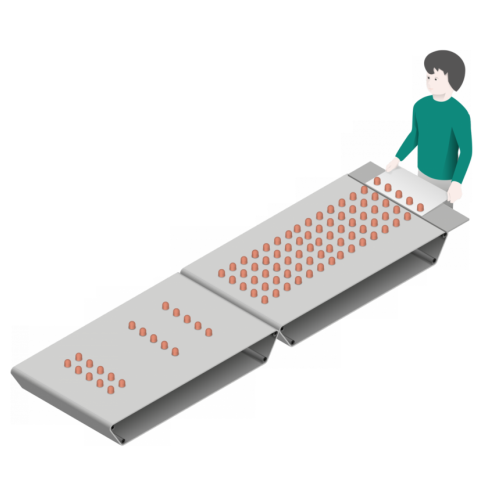

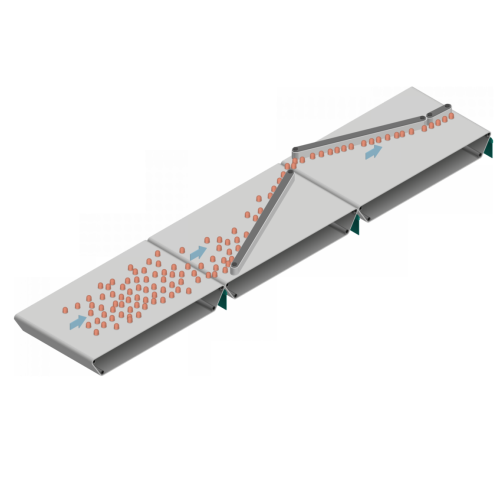

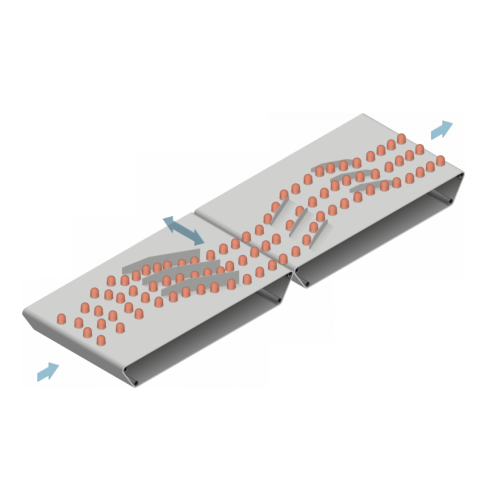

Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensu...

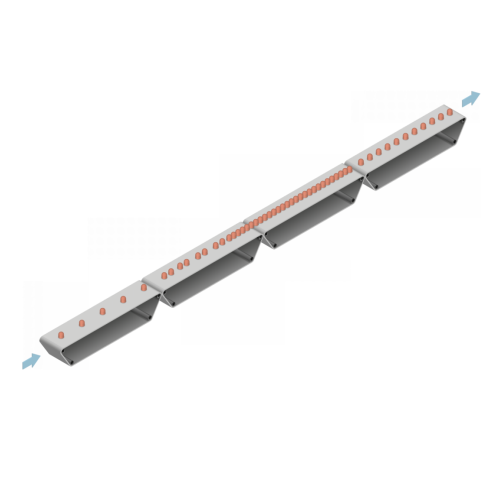

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confect...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

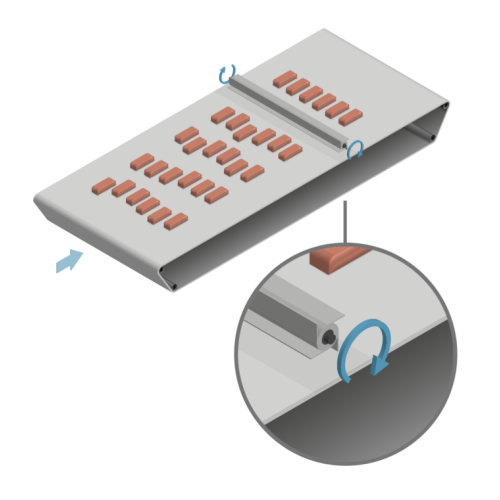

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

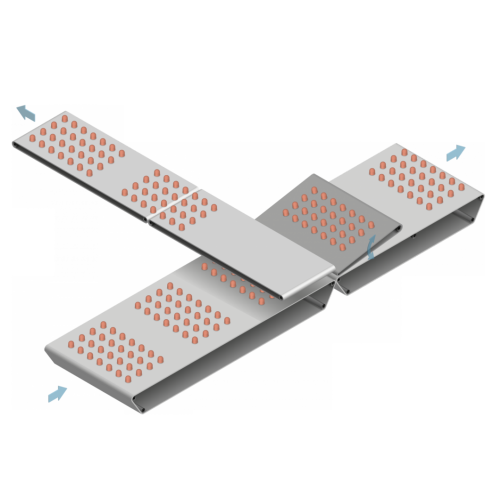

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

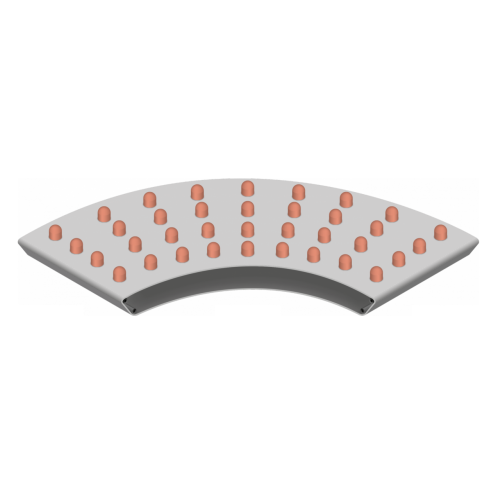

Curved conveyor for product transport

Streamline your product flow with a versatile curved conveyor, perfect for maintainin...

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

High-speed wrapping solution for compressed powder products

Efficiently wrap high-volume compressed powder products with...

Modular high-speed forming, cutting, and wrapping for soft caramels

Streamline your confectionery production with a hig...

High speed wrapping solution for hard candies and toffees

Enhance your production with a high-speed solution designed fo...

High-speed packaging machine for bouillon cubes

Streamline your production process with a machine designed to handle up to...

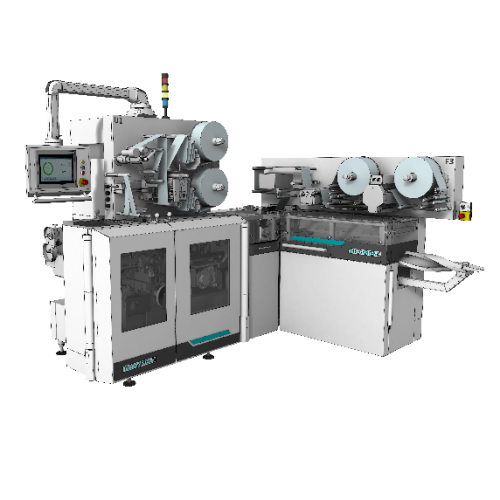

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Retrofit package for Ek1 packaging system

Upgrade older packaging systems to enhance efficiency and flexibility while acco...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

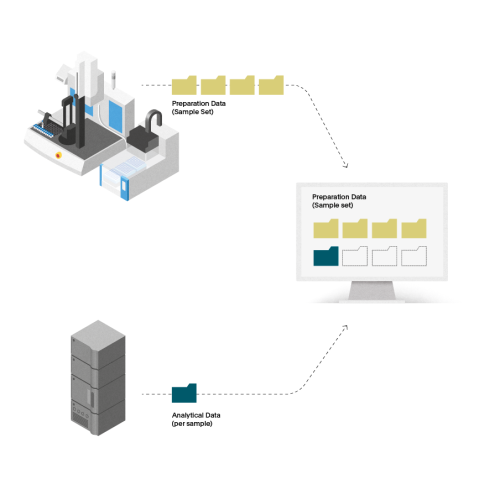

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

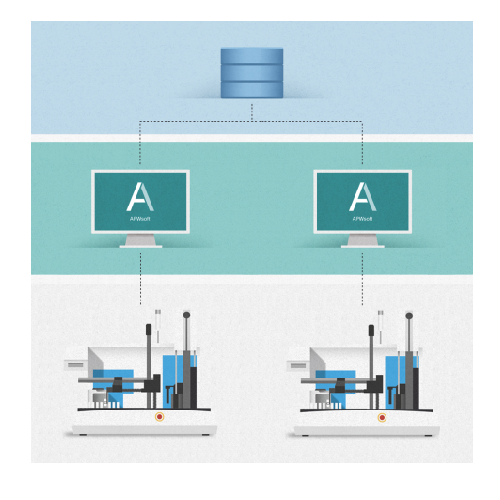

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

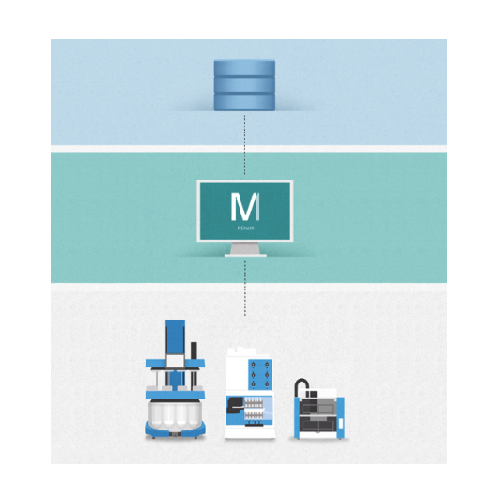

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

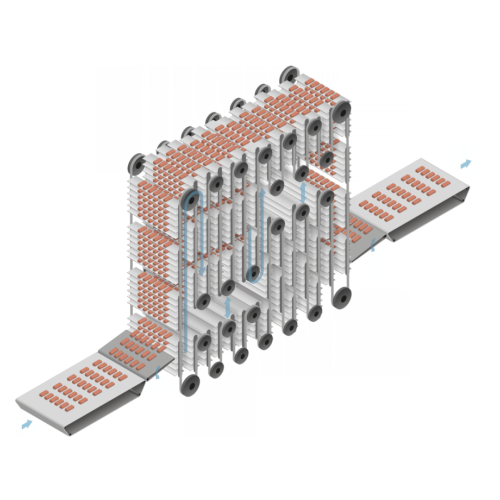

Fully automated dishwasher tablet press

The process of making dishwasher tablets that have more than one layer is very deli...

Three-layer dishwasher tablet press

Dishwasher detergent tablets come either in a single layer or multi-layer form. Multi-l...

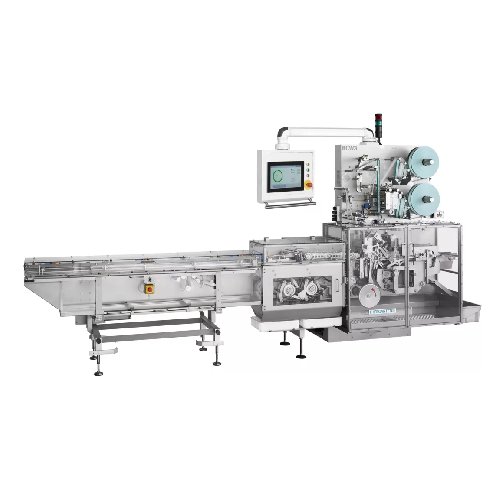

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Compact powder pressing machine

Pressed powder products are extremely popular in cosmetics, but their production has challen...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...