Making Liquid Detergents

Find innovative production technology for making liquid detergents and connect directly with world-leading specialists

Although invented in the early 20th century by Otto Rohm, detergents gained popularity in the 1950s due to the development of modern technology and washing machines which started replacing scrub boards. The liquid detergent manufacturing process involves three key stages: soap premix manufacture, ingredient mixing and enzyme addition.

Select your liquid detergents process

Tell us about your production challenge

The essential steps in the liquid detergent manufacturing process

In addition to liquid laundry and dish-washing liquid detergents, household cleaners such as floor cleaning liquids or glass cleaners are also classified as liquid detergents. All these detergents can be produced in the same plant. Substantially, liquid detergents are powders mixed with water and chemical solutions called solubilizers, making detergents dissolvable in water. The first stage of the liquid detergent manufacturing process consists of neutralizing fatty acids with either caustic soda or potassium hydroxide.

After the chemical reaction and the premix step, ingredients such as thickeners and pH adjusters are added to a homogeneous mixer. These balancing ingredients are essential to achieve desirable viscosity, stability, and pH value. In the enzyme addition stage, powdered enzymes are added to the cooled mixture due to their delicate nature.

Their role is to break down tough stains and soils. Enzymes like lipase are good for removing grease and oil while amylase, for instance, can remove starch-based or carbohydrate soils. Lastly, liquidized detergents are pumped into bottles by a filling system, weighted on weighing devices and sealed by a capping machine.

What’s the difference between liquid dishwashing detergent and liquid laundry detergent?

The formula of the two liquid detergents is almost very similar even though, if you think about it, they are designed for totally different applications.

Since dishwashing detergents are designed for frequent contact with human skin they contain mildness additives and antibacterial agents. Moisturizing agents, oils and protein compounds are added to protect the skin and prevent tears. They also contain chelating agents and preservatives due to oxidation. Furthermore, dishwashing detergents use sodium Laureth sulfate as a surfactant which acts as a foaming agent.

On the contrary, surfactants used in liquid laundry detergents are alkyl or aryl sulphonates, which restrict suds. The use of enzymes in laundry detergents is essential since they exterminate stains that grip the fabric. Moreover, laundry detergents use ingredients specified for protecting fabric and washing machine parts. Builders improve the effectiveness of the surfactant, polymers help capture soils and prevent dye from coming off and transferring to textile, bleach preserves color while softeners reduce fabric friction. Finally, corrosion inhibitors protect the parts of washing machines from corrosion.

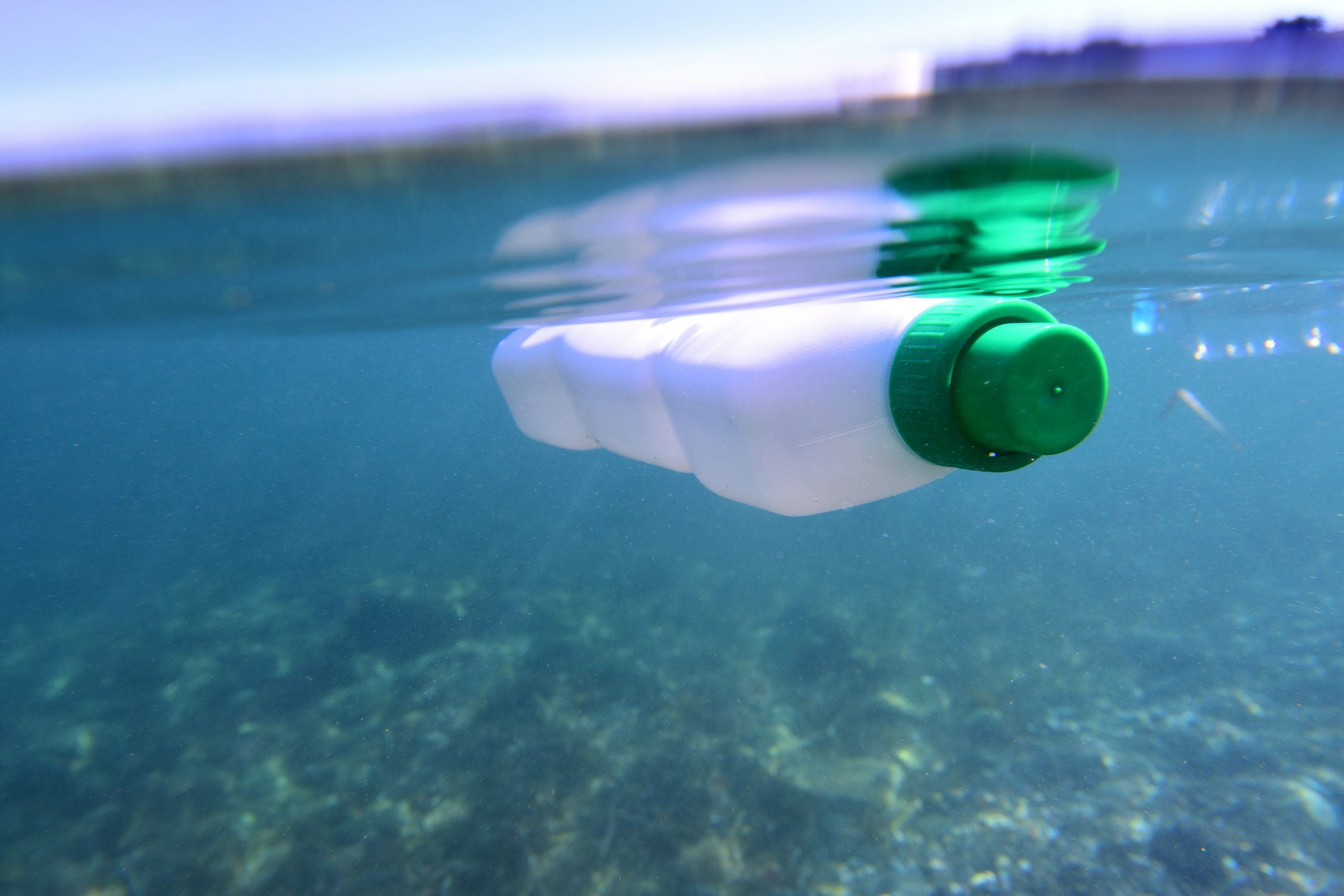

The environmental impact of liquid detergents

In recent years, the detergent industry has faced various environmental challenges, since detergents contain several harmful chemicals. Surfactants damage the protective layers of fish, leaving them vulnerable to parasites, bacteria and other pollutants. Another problem caused by a standard surfactant was foam creation in the nation’s waterways. It was discovered that the problem was caused by ABS (alkyl-benzene sulfonate). Nowadays, manufacturers replaced ABS with LAS (linear alkylate sulfonate), which biodegrades faster than ABS.

Although phosphates were banned for causing eutrophication by inducing algae population explosions, environmental damage is still driven by its alternatives. Chemicals such as nonylphenol ethoxylated, acetaldehyde and benzene further contribute to water and air pollution.

Additionally, liquid detergents are sold in plastic bottles, which end up in oceans, waterways and landfills. However, manufacturers of liquid detergents are looking for solutions to avoid harming the marine environment. Eco-friendly solutions are being developed such as detergents made with plant-based ingredients and biodegradable packaging.

Processing steps involved in liquid detergents making

Which liquid detergents technology do you need?

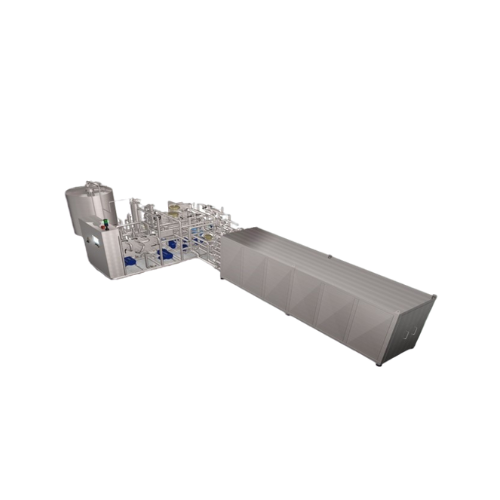

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

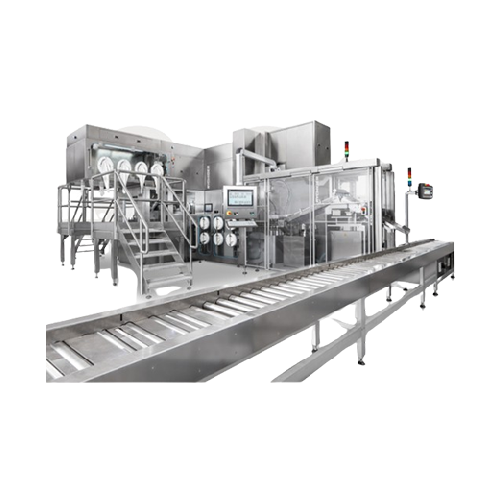

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

In-line weight filler for drums and kegs

Achieve precise and efficient weight-based filling for large liquid containers, en...

Depalletiser for bulk products

Efficient and precise, this depalletiser streamlines your bulk product handling by seamlessly...

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

Rotary weight filler for Pet and Hdpe bottles

Enhance your production line with precise weight-based filling, ensuring rap...

Laser guided vehicle for pallet handling

Efficiently streamline your internal logistics with cutting-edge laser guidance, e...

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

Pallet handling system

Streamline your production line with advanced pallet handling solutions that efficiently automate conv...

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

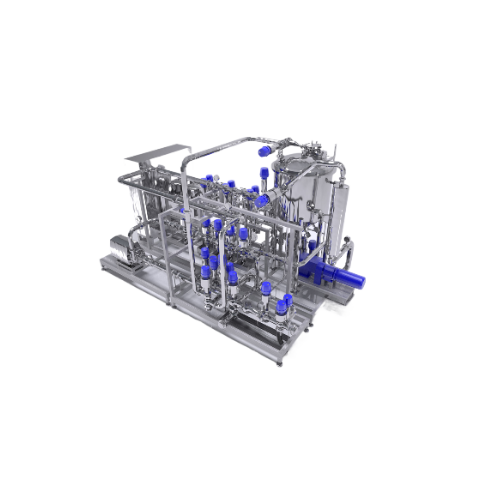

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

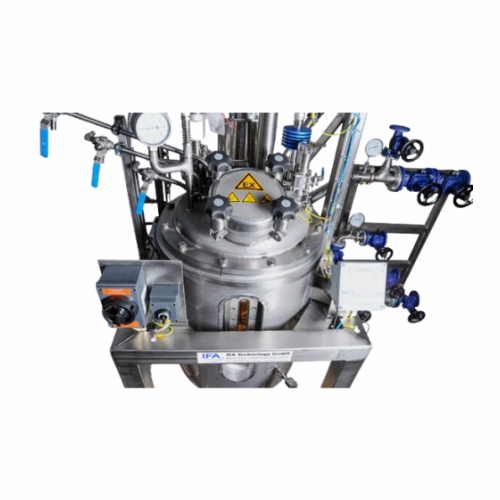

Versatile magnetic mixer for pharmaceutical and biotechnology applications

Optimize your biopharmaceutical mixing proc...

4 head sealing system for plastic and glass jars

Achieve precision sealing for jars of various materials with this high-sp...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

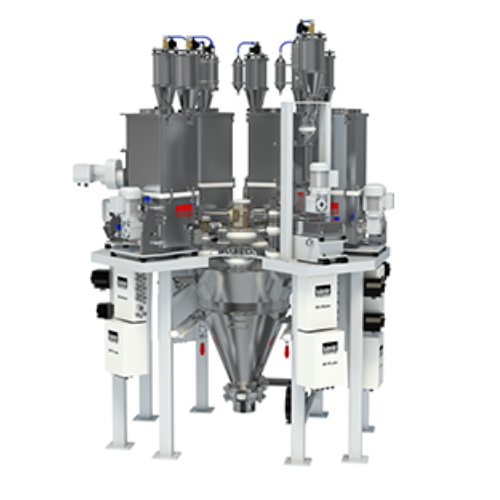

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

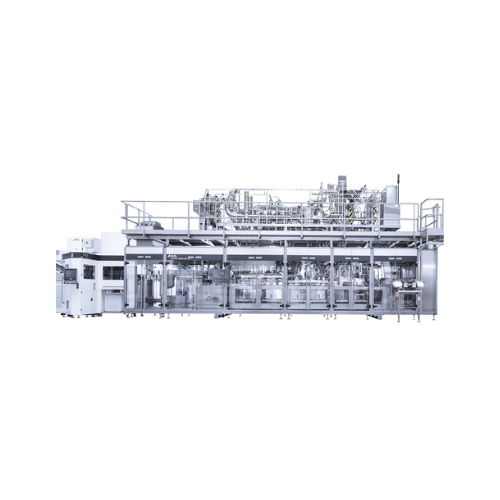

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Compact cleaning system in container format

Optimize your production lines with a space-saving cleaning system capable of ...

Twin-column palletizer for beverage and food packaging

Achieve seamless operation with a flexible twin-column design that...

Glass bottle filler for beer and soft drinks

Optimize your beverage production with a high-speed filling solution that red...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

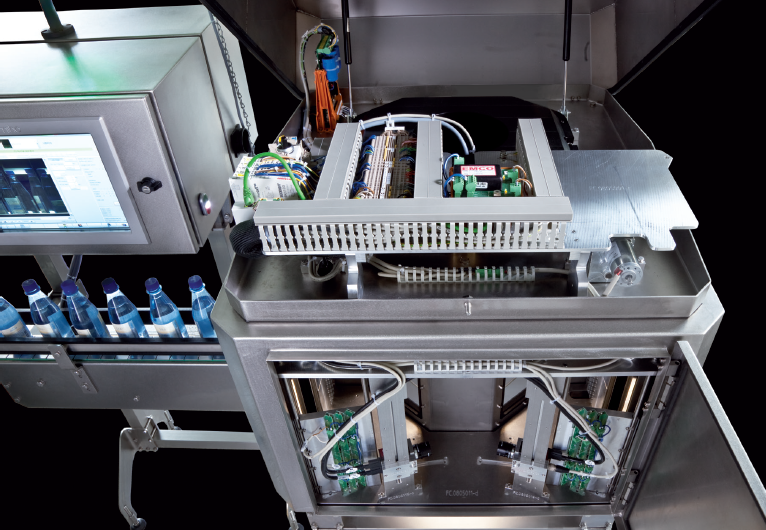

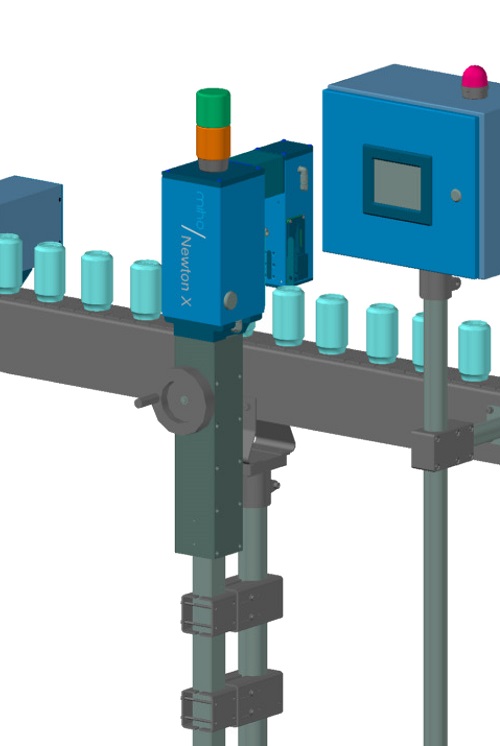

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Positive displacement gear pump liquid filler

Optimize your liquid filling operations with precision gear pump technology,...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

Precision case rejector for faulty packaging

Ensure seamless production flow by reliably removing defective packaging with...

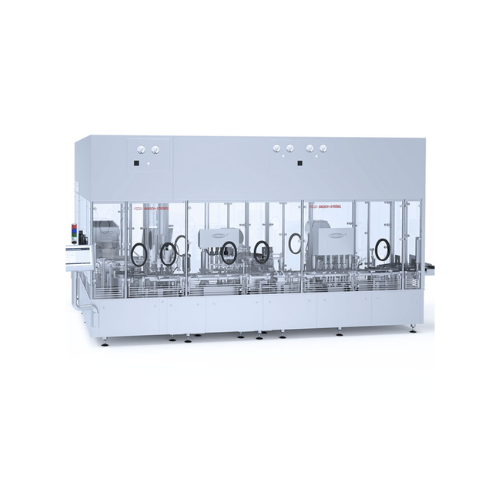

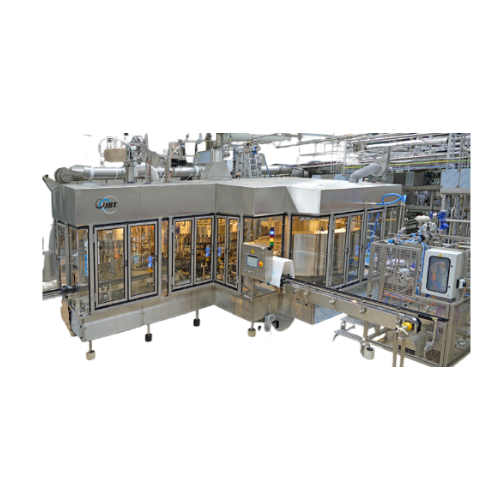

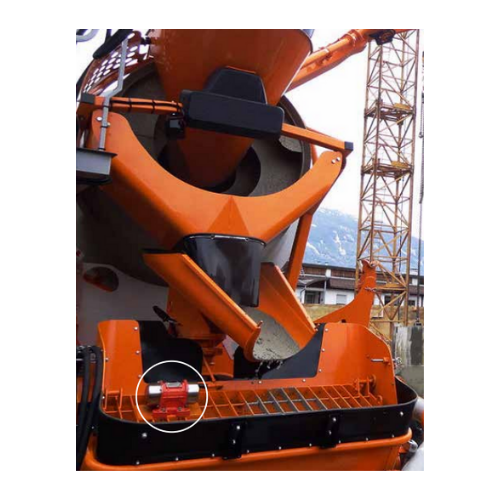

Integrated packaging system for cement and building materials

Streamline your packing operations with a fully enclosed s...

Integrated packaging system for valve and tubular film bags

Achieve precision and efficiency in your packaging line with...

Small batch free fall mixer for food industry applications

Efficiently handle diverse ingredient integration for plant-b...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Automatic cartoning solution for 3-20l aseptic bags

Streamline your aseptic packaging with an integrated cartoning soluti...

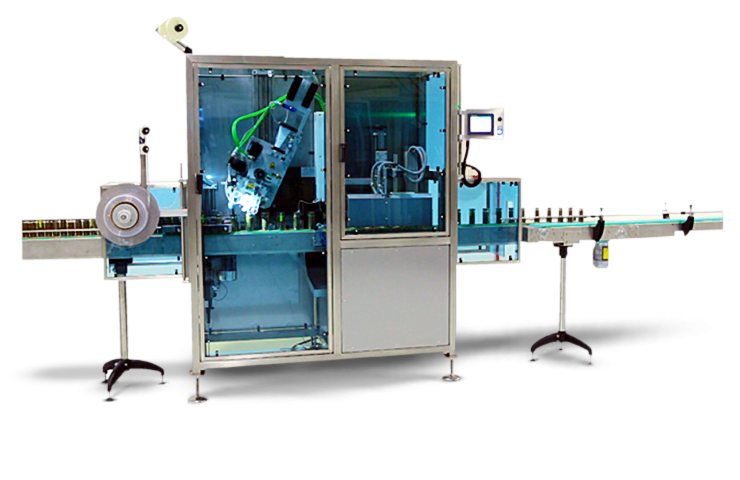

High speed wraparound label applicator for cylindrical containers

Experience efficient high-speed labelling for cylindr...

Horizontal flat pouching system for liquid soaps

Optimize your liquid packaging with high-speed, continuous operations tha...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Manual bag-in-box filling solution

Streamline your liquid packaging with a compact, easy-to-operate filling system that sim...

Manual pneumatic filler for bag-in-box

Experience seamless filling for liquid formulations with this pneumatic solution, en...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

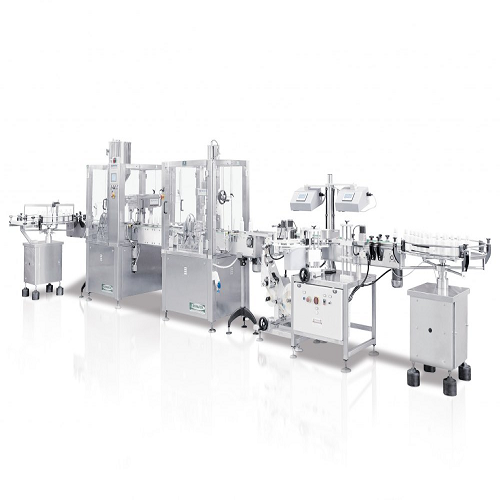

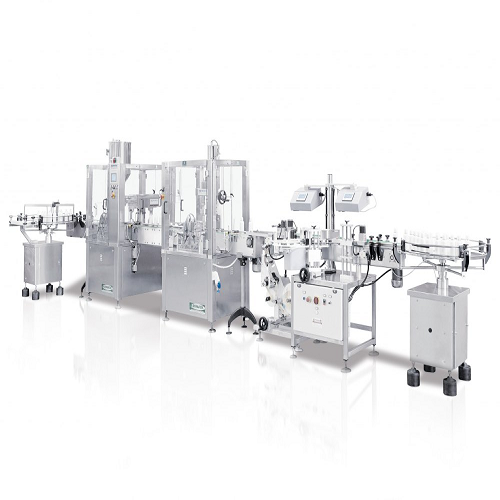

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

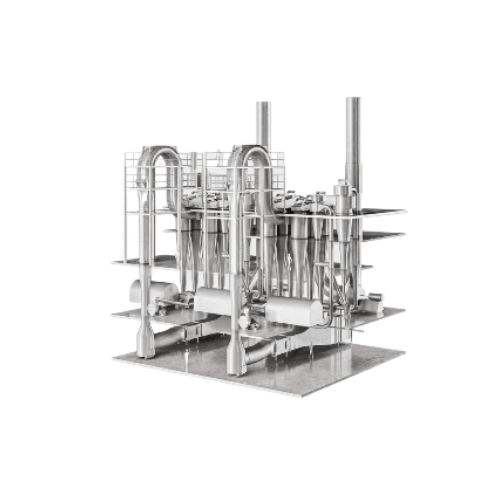

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Industrial water chiller for homogenizers and filling machines

Optimize your production line with customizable water chi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Semi automatic Pet bottle blow molding solution

Streamline your production with a semi-automatic solution designed for eff...

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

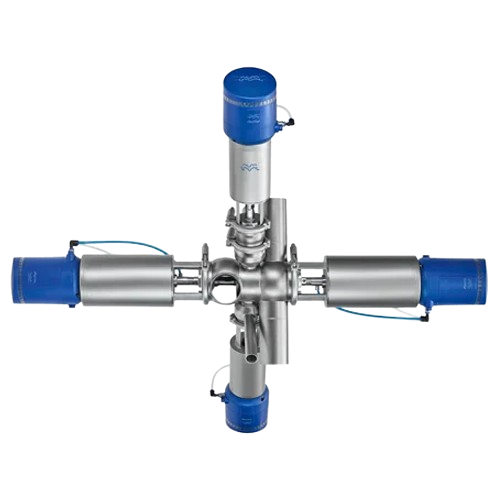

Aseptic mixproof valve for sterile processing

Ensure absolute product safety and optimize cleaning efficiency in sterile p...

Hybrid powder mixer for powder-liquid blending

Achieve consistent powder-liquid blends with reduced processing times and e...

Rotary jet mixer for efficient liquid, gas, and powder mixing

Achieve seamless integration and efficiency in liquid, gas...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Automated bottle and jar filling solution

Streamline your production and minimize waste with a versatile filling solution,...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Automatic induction sealer for cap sealing

Achieve precise and reliable cap sealing with our advanced induction technology...

Ultrasonic tube sealer for plastic tubes

Seal plastic tubes with precision and speed using our ultrasonic technology, ensur...

Steam shrink tunnels for versatile packaging

Enhance your packaging efficiency with this adaptable steam shrink tunnel, de...

Automatic bottle washer for packaging lines

Ensure your bottles are impeccably clean and ready for filling, as this soluti...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Bottomless conveyor for 90° bottle transfer and coding

Efficiently connect disparate production systems in your bottling ...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Automatic pressure sensitive labeling system

Enhance your production line’s efficiency with a versatile labeling sys...

Container unscrambler for filling lines

Streamline and automate the loading of containers onto your production line with th...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

Industrial ejectors for reliable jet pump applications

Enhance process efficiency and reliability with industrial ejector...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Homogenizing mixer for product distribution

Optimize the flow of your production with a high-speed distributor mixer, ensu...

Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with conti...

Pilot plant homogenizer for continuous operation

Achieve consistent fluid textures and prolonged shelf life with high-pres...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Powder wetting and dispersion system

Revolutionize your production with a system that seamlessly inducts, wets, and dispers...

Inline disperser for homogeneous emulsions and suspensions

Achieve precise control over particle size and distribution w...

X-ray inspection system for wet environments

Ensure unparalleled product inspection under extreme cleaning conditions with...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

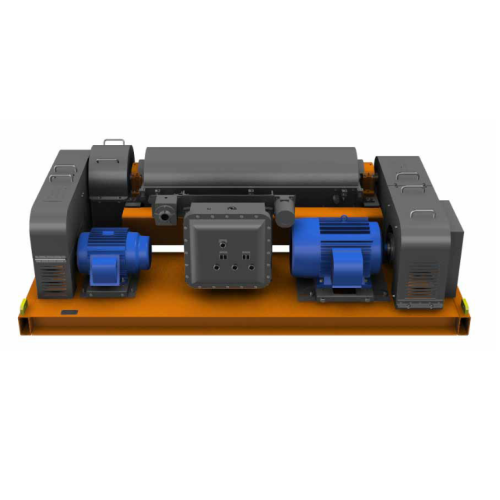

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

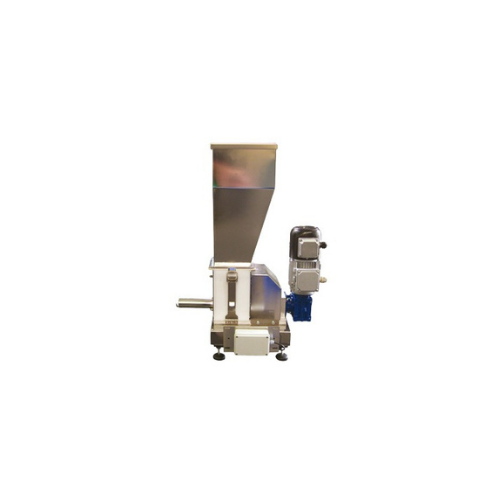

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

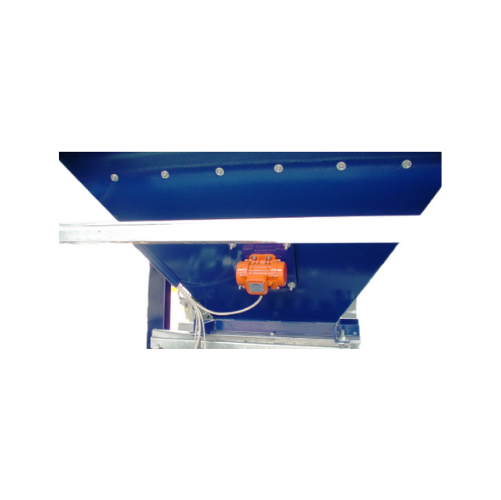

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Accurate pharmaceutical dispenser for high-viscosity fluids

Achieve precise liquid dosing with ease, designed to handle ...

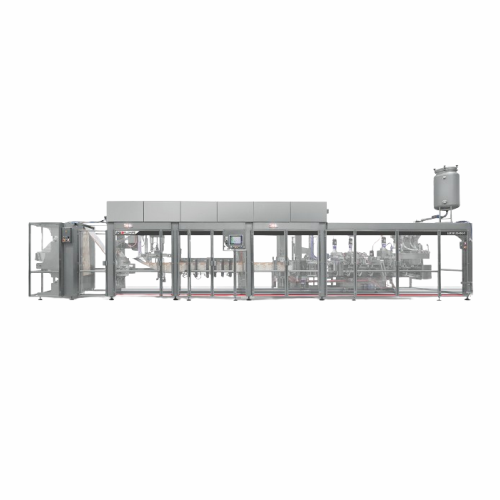

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

Pressure monitoring solution for dosing processes

Optimize your production line by ensuring precise pressure monitoring, ...

Automated precision spraying dispenser for high viscosity materials

Achieve precise spraying and consistent coating res...

Magnetic coupling agitator for sealed mixing

Achieve leak-free, hermetically sealed mixing for critical and aggressive med...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Vessel dome fittings for tank protection

Ensure seamless production by preventing tank damage due to overpressure or vacuum...

Bottle filling system for diverse specifications

Optimize your bottle-filling operations with a modular system that seamle...

Agitator for Ibc containers

Achieve consistent and efficient mixing of various liquid products with this agitator, ensuring ...

Agitator for bulk containers

Achieve consistent mixing results for low-to-medium viscosity liquids in bulk containers with o...

Automatic liquid filling solutions for various containers

Ensure precise liquid packaging for diverse container types, e...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Manual dosing and capping for semi-dense products

Enhance your production line efficiency by seamlessly integrating manua...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Vibratory finishing and deburring technology

Achieve precise surface finishing and deburring with advanced vibratory motio...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Side entry mixer for industrial tank applications

Ensure optimal mixing and blending of liquids and slurries with high ef...

Solids retaining separator for liquid/liquid/solid separation

Achieve precise liquid-liquid-solid separation even with l...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

Loss-in-weight feeder for liquids

Achieve precise and continuous liquid dosing with high accuracy, adapting seamlessly to y...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Hopper scale for precision batching

Achieve high batch accuracy with a central weighing hopper engineered for seamless inte...

Batch ingredient dosing system for high-accuracy weight control

Achieve precise weight measurement for multi-ingredient ...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

Loss-in-weight feeder for long and uneven fibers

Optimize feeding precision for challenging materials like long and uneven...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

Integrated preform production and bottling system for Pet bottles

Achieve seamless production of PET bottles, from pref...

Volumetric filler for Pet bottle beverages

Experience seamless integration into your bottling line with this advanced volu...

Anti-corrosion filling system for aggressive liquids

When dealing with corrosive liquids, ensure durability and safety wi...

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

Semi-automatic weight filling system for liquid products

Achieve precise and versatile liquid filling performance with th...

Blow-fill-cap solution for low/medium batch production

Streamline your production line with a compact blow-fill-cap syste...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Cannabis nanoemulsification system for high-precision production

Achieve rapid bioavailability and stable formulations i...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Low speed Filler for large-volume parenterals

Large-volume parenteral bottles are usually manufactured with a resin that c...

Automatic bottle capping machine

Traditional bottle capping systems are inflexible, limiting the scope of your packaging and...

Acid filling machine

Traditional filling solutions are not appropriate for corrosive substances as they make extensive use of...

Semi-automatic trigger capping machine

Trigger spray bottle are the ideal capping solution for many chemical and household ...

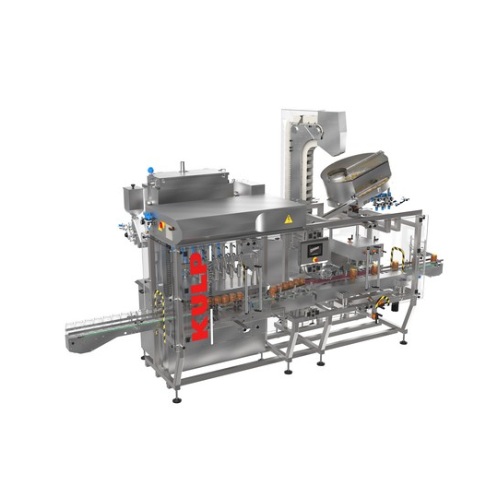

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Electric shrink tunnel solution

Adapting shrink sleeve heating tunnels for different applications can be a lengthy and expen...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Laboratory size auto-steam shrink system

When managing sleeving projects, fast prototyping and testing can gain massive com...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...