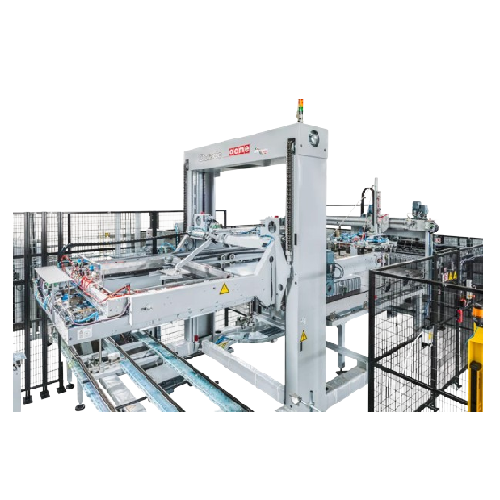

Depalletiser for bulk products

Efficient and precise, this depalletiser streamlines your bulk product handling by seamlessly integrating with high-speed operations, optimizing layer transfers, and ensuring consistent output without manual intervention.

Unwraps, Depalletizes, and Transfers Bulk Products

The Dorado depalletiser from OCME is a versatile machine tailored for high-speed bulk product handling across beverage, food, and personal care industries. It stands out with its dual-mode operation, capable of processing up to 360 layers per hour in high infeed level with a moving pallet configuration, and 150 layers per hour with a low infeed level and steady pallet setup. This flexibility allows for seamless integration into various production lines, maintaining a continuous flow through the precise unwrapping, depalletizing, and extraction of products like HDPE jerry cans, PET bottles, and corrugated boxes.

Dorado operates with an advanced gripping head mechanism featuring self-centering plates or rotating bars, ensuring accurate and safe layer transfer. Its encoder-controlled height detection enhances operational precision, while inverter-controlled pallet conveyors improve energy efficiency. Designed with operator safety in mind, the equipment includes an accessible platform for manual tasks, minimizing downtime and facilitating maintenance.

Equipped with Industry 4.0 capabilities, Dorado offers remote monitoring and control through its user-friendly HMI interface, aligning with modern automation needs. It supports customization to handle non-standard pallets and includes options like strap removal and neck orientation controls, maximizing adaptability within your specific production environment.

Benefits

- Enhances production efficiency with high-speed processing up to 360 layers per hour.

- Optimizes safety and precision with encoder-controlled operations and self-centering gripping technology.

- Lowers energy costs through inverter-controlled pallet conveyors.

- Adapts to diverse production needs with customizable options for non-standard pallets and products.

- Facilitates maintenance and reduces downtime with easy access operator platforms.

- Applications

- Food, Personal care, Beverage, Tissue, Lubricants, Paper, Corrugated, Home

- End products

- Pet water bottles, Aluminum beverage cans, Liquid detergent containers, Paper tissue rolls, Hdpe jerry cans, Shampoo bottles, Corrugated cardboard boxes, Motor oil containers

- Steps before

- Palletizing, Product wrapping, Pallet loading

- Steps after

- Packing, Conveying, Sorting

- Input ingredients

- hdpe containers, jerry cans, cans, bottles, pallets

- Output ingredients

- single row packs, layers

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Infeed Level

- Low with steady pallet (LF) / High with moving pallet (HM)

- Speed

- Up to 360 layers/hour (HM) / Up to 150 layers/hour (LF)

- Automation

- Industry 4.0 ready / Inverter-controlled pallet conveyors

- Operator Platform

- For pallet unwrapping operations

- Height Control

- By encoder

- Safety Standards

- High level components

- Gripping Head

- Self-centering plates (LF) / Rotating bars (HM)

- Layer Transfer Precision

- Maximum precision and safety during layer transfer phase

- Flexibility

- High flexibility to process various types of packs

- Automation level

- Manual / PLC / HMI-controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Not specified

- Cleaning method

- Manual

- Energy efficiency

- High efficiency design

- Products compatibility

- HDPE containers, jerry cans, cans, bottles

- Corrosive resistance

- Yes

- Process flexibility

- Various types of packs

- Abrasion resistance

- High

- Cleanability

- High

- Container type

- HDPE containers, jerry cans, cans, bottles

- Machine footprint

- Compact

- Product Infeed Level

- Low with Steady Pallet / High with Moving Pallet

- Operator Platform

- Included for pallet unwrapping operations

- Gripping Mechanism

- Self-centring plates / Rotating bars

- Pallet Conveyor Control

- Inverter-controlled

- Height Control

- Encoder-based

- Customization

- Available according to customer specifications

- Machine version

- Standard / Non-standard pallets

- Strap removing device

- Included

- Side conveyor

- Gradual product outgoing

- Tank neck orientation control

- Included

- Pallet conveyor control

- Inverter-controlled