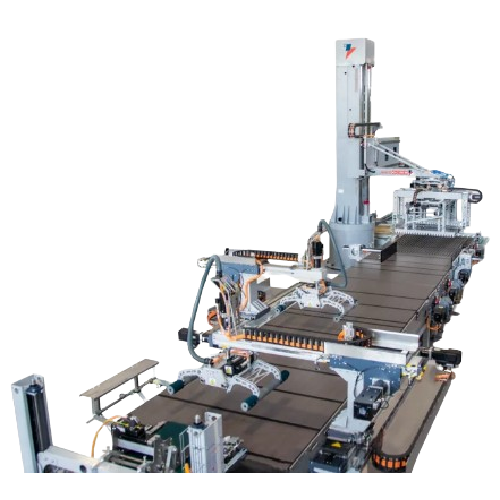

Single-column palletizer for medium to high production

Optimize your production line efficiency with a versatile single-column palletizer designed to handle diverse product types, ensuring precise handling and compact footprint for seamless integration into existing systems.

Palletizes and Organizes Products Efficiently

The Ares Single-Column Palletizer by OCME is a versatile solution designed to meet the challenges of diverse industries, including beverage, food, and personal care. This equipment stands out with its adaptable gripper head technology, seamlessly handling products like cartons, trays, and bundles with precision.

The Ares integrates a streamlined process for efficient layer forming and palletizing, accommodating both inline and 90° product infeed configurations. Operating at a maximum speed of 420 layers per hour, it ensures optimal throughput for medium to high production capacities. The system is fully automated, featuring a PLC control with options for remote monitoring, enhancing production line integration.

Energy efficiency is achieved through its brushless motor technology, minimizing energy consumption while maximizing performance. The optional Mizar Layer Forming System incorporates manipulators that offer precise and shock-free product handling, crucial for fragile items.

Constructed for durability, the Ares offers customization options to fit specific operational needs, including gripper head modifications and material choices to enhance corrosion resistance. With a focus on ease of use, it supports quick format changes and easy access for maintenance, significantly reducing downtime. Additionally, OCME provides customization support, ensuring the Ares aligns perfectly with your unique production requirements.

Benefits

- Enhances production efficiency with high-speed palletizing up to 420 layers per hour.

- Saves energy with brushless motors, reducing overall power consumption.

- Adapts to various product types with customizable gripper heads, ensuring gentle handling.

- Minimizes manual intervention with fully automated, remote-monitoring capabilities.

- Speeds up changeovers and maintenance with quick access and easy format adjustments.

- Applications

- Food, Personal care, Paper and tissue, Beverage, Cartons, Trays, Lubricants, Bundles, Home, Corrugated products

- End products

- Glass jars of jam, Detergent boxes, Bottled water, Engine oil containers, Facial tissue packs, Milk cartons, Plastic trays with food wrap, Soft drink cans, Multipack bundles of snacks, Shampoo bottles, Corrugated cardboard boxes

- Steps before

- Packing, Internal Logistics, Filling

- Steps after

- Stretch Wrapping, Banding

- Input ingredients

- pallets, layer pads, trays with film, trays, cartons, bundles, unstable products, fragile products

- Output ingredients

- palletized products, stacked products, precision pallet layers, reliable palletized stacks

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Machine Type

- Single-column palletizer

- Maximum Speed

- 420 layers/hour

- Automation

- Fully automated

- Flexibility

- High adaptability for product needs

- Layer Forming System

- Integrated

- Accessibility

- High

- Product Infeed Type

- In-line or 90°

- Pallet Type

- Fixed pallet version and High level infeed

- Level Compensation

- Yes

- Customization

- Curtain clamp customizable

- Feeding System

- Automatic feeding system for layer-pads

- Empty Pallet Infeed

- Included

- Product Handling

- Sensitive product handling capability

- Packing Arrangement

- MIZAR Layer Forming system for optimal packing

- Manipulation Control

- Brushless motorized gripping heads

- Program Creation

- Program maker software with 3-D previews

- Speed

- Medium/high production capacity

- Automation level

- Fully automated

- Changeover time

- Fast format changes

- Product handling care

- Sensitive products

- Compactness

- Extremely compact

- Flexibility

- User friendly

- Level compensation feature

- Yes

- Speed

- 420 layers/hour

- Reliability

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Sensitivity

- Sensitive Products

- Production Capacity Requirement

- Medium/High

- Machine footprint

- Extremely compact

- Control panel type

- User friendly

- Discharge method

- Inline or 90° product infeed

- Palletizer type

- Single-column

- Adaptability

- Individually adaptable

- Control panel type

- User friendly

- Integration possibilities

- Layer forming system integration

- Gripper head

- Customizable for product needs

- Pallet infeed system

- Supports variations in pallet size

- Layer-pad feeding system

- Automatic

- Program maker interface

- Customizable palletizing patterns

- Interacting gripper type

- Column type or robotic type