Making Laundry Detergent

Find innovative production technology for making laundry detergent and connect directly with world-leading specialists

Laundry detergents are currently on the rise due to increasing urbanization and the need for automation. The global market will reach $98,139.7 million by 2030 from $61,711.0 in 2020, influencing the demand for laundry detergent equipment. Unlike in Western countries, powdered detergents are more popular in Asia and China because they’re cheaper.

Select your laundry detergent process

Tell us about your production challenge

Laundry detergent equipment and key process

Producers of laundry detergents either use the dry mixing method, the agglomeration process, or the spray drying method to make laundry detergents. However, spray drying is the best method because it produces a lightweight, well-hydrated product that doesn’t cake. In this technique, a mixer combines the surfactant with a builder like sodium silicate to form a slurry that ages in an aging tank. They spray dry the mixture in a spray drying tower, filter it, modify it with enzymes, fragrances, and colors, and move it to a storage machine for packaging.

Factors to consider in the washing powder production line

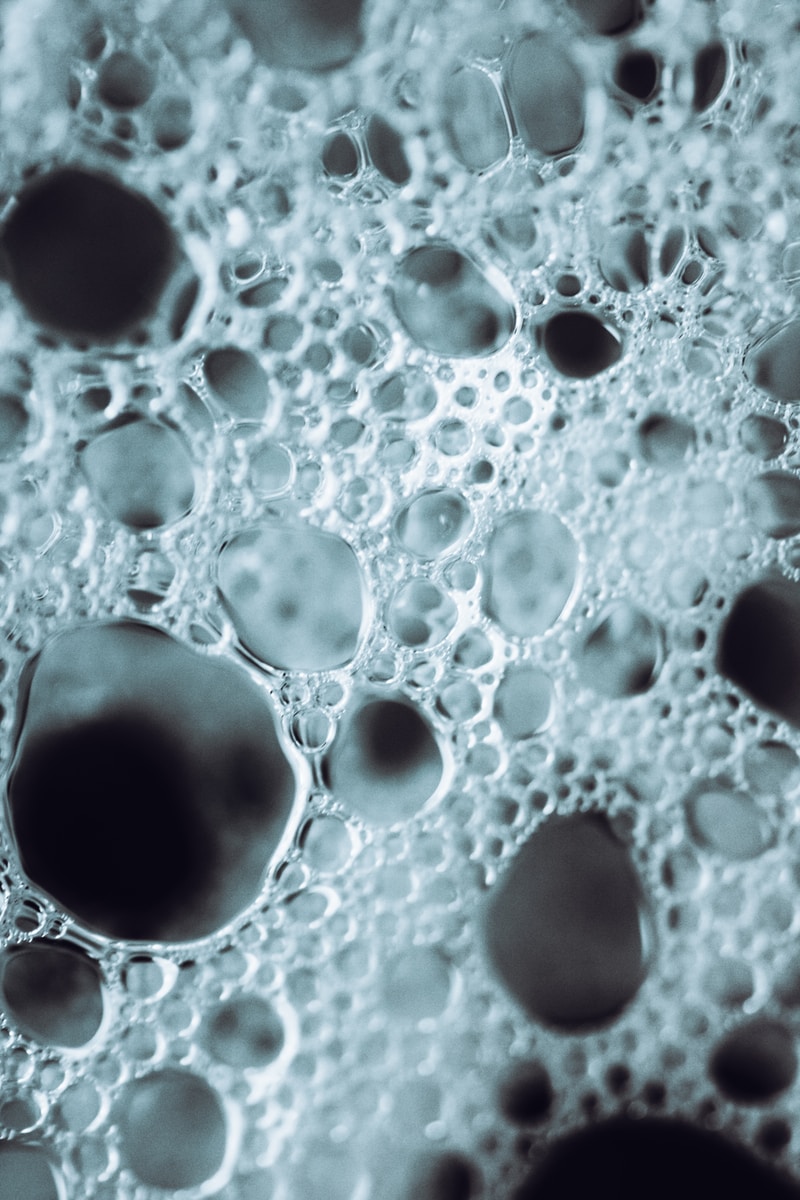

When formulating the product in the washing powder making machine, it’s essential to pay attention to the pH of the washing powder to ensure it is compatible with the human skin and can clean effectively. The optimum pH range for laundry detergent is 9-10.5. Alkalinity converts insoluble fatty acids to soluble salts that wash away easily. Ingredients like surfactants are necessary ingredients in the production. They reduce the surface tension of hard water to prevent the formation of an insoluble precipitate that leaves visible deposits on fabrics and makes them unappealing.

The environmental impact of laundry detergents

Detergents contain some harmful chemicals such as nitrogen and phosphate. Nitrogen reacts with phosphorus in water to create nutrients that stimulate algae growth in freshwater. Algae then utilize the oxygen in the water in a process called eutrophication. Eventually, this depletion in oxygen damages the ecosystem.

In addition, surfactants reduce the surface tension of water and make it easier for waterways to absorb pollutants and pesticides. An effective solution is to feed materials from plant sources into laundry detergent equipment to produce eco-friendly alternatives. But the challenge with creating environmentally safe detergents is the high cost of production. Ingredients from plants are more expensive than their synthetic counterparts.

Are laundry detergent pods safe?

Laundry pods have become popular due to their convenience. They contain water-soluble polyvinyl alcohol and liquid cleaning agents in pods. Unlike regular laundry detergents, they are pre-measured to provide a consistent result.

Its production eliminates water, allowing the cleaning ingredients to remain stable for a long period. Laundry pods are a good laundry detergent option; however, the concern about laundry pods is how unsafe they can be for children, who could mistake them for candies. As part of the safety rules, producers have been advised to make them child-proof by using child-safe caps and making sure opening them requires both hands.

Processing steps involved in laundry detergent making

Which laundry detergent technology do you need?

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

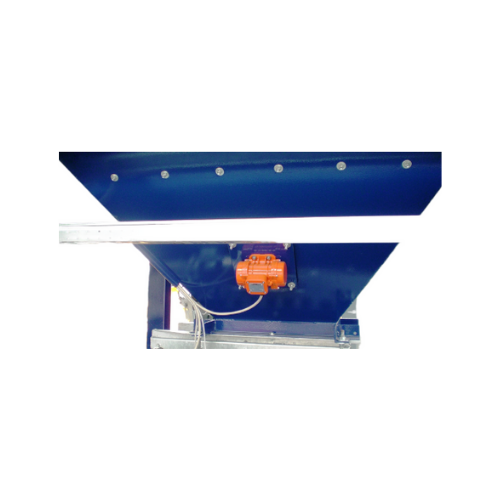

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

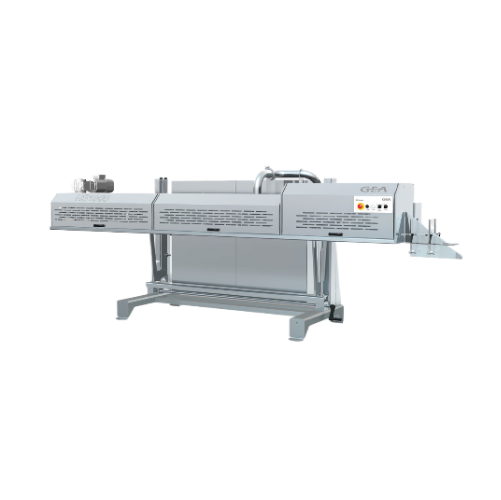

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

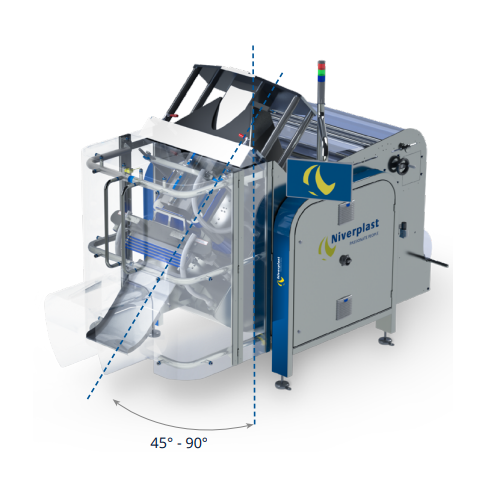

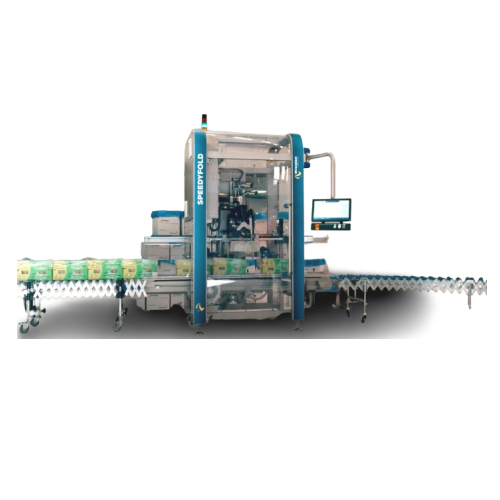

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

High-speed in-line palletizer for beverage industry

Effortlessly streamline your palletizing processes with a compact, hi...

Laser guided vehicle for shuttle management in warehouses

Optimize your warehouse operations with a precision-guided veh...

Fully automatic rotary ring wrapper for large pallets

Optimize packaging efficiency by securing large, diverse pallet loa...

Fully automatic horizontal banding solution for labeling

Optimize your packaging line with a sophisticated banding system...

High-speed wrap-around case packer for beverage industry

Optimize your packaging line with a high-speed case packer that ...

Fully automatic double rotary arm wrapper

Achieve high-speed load stabilization with our double rotary arm wrapper, design...

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

High-speed camera counting system for accurate product batching

Optimize your production line with a cutting-edge system...

Automated system for placing bags in boxes and crates

Streamline your packaging process with high-speed bag placement tha...

Touch-free layer packaging for bakery products

Optimize your packaging line with a touch-free solution that ensures hygien...

High-speed bag placing system for e-commerce fulfillment centers

Optimize your packaging line with a high-speed system t...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Automated bag folding for packaging

Streamline your packaging operations with a high-speed solution that seamlessly integra...

Automatic bag sealer for varied box sizes

Seamlessly integrate this high-speed bag sealing solution to enhance productivit...

Automatic laundry compressing and packing

Efficiently compress and pack textiles with precision, achieving up to 37.5% vol...

Automatic bag sealing system for packaging operations

Optimize your packaging efficiency with this high-speed sealing sys...

Self-driving transport system for industrial packaging

Streamline internal logistics with a self-navigating vehicle desig...

Compact palletizing solution for limited space

Optimize your space with versatile palletizing that adapts to diverse produ...

Automated paper bag placing system

Efficiently automate the placement of paper bags into totes or boxes with precision and ...

Camera quality control for industrial production

Ensure flawless product quality by integrating a precision optical inspec...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Compact sealing system for bags and boxes

Achieve seamless, high-speed packaging with a compact solution designed to handl...

Case erecting and bag placing system

Streamline your packaging process with a compact system that integrates case erecting ...

Bag folding solution for high-speed packaging

Effortlessly enhance your packaging line efficiency with this high-speed bag...

Manual bag placing solution for various materials

Increase your efficiency in manual bag placing with an ergonomic soluti...

Automated bag placing solution for industrial packaging

Maximize efficiency with a versatile bag placing system designed ...

Particle size and shape analyzer

Achieve precise particle size and shape analysis from 0.8 μm to 8 mm with exceptional speed...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

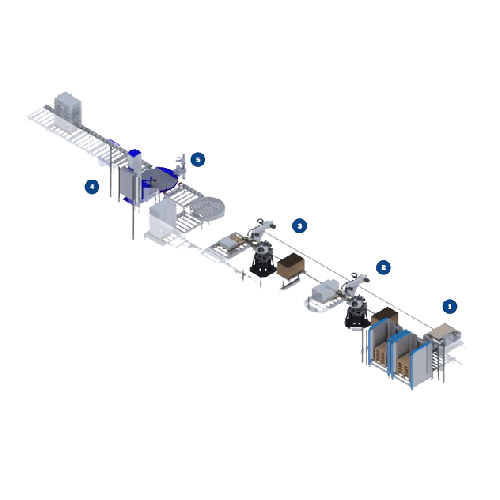

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

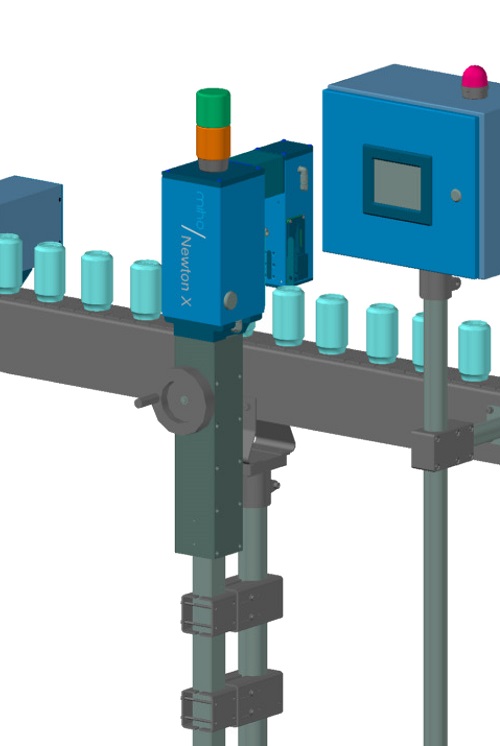

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Labelling solution for cylindrical containers

Achieve precise and efficient labelling for cylindrical containers with a sy...

High impact mixer for powders and liquids

Achieve highly homogeneous mixtures with precision. This high impact mixer excel...

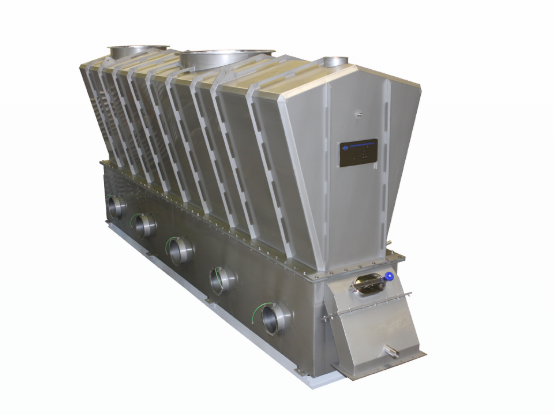

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

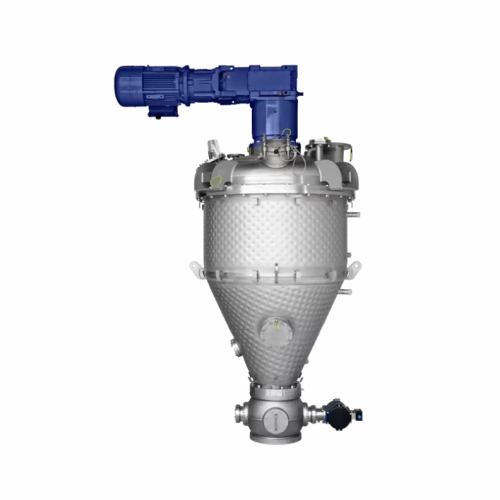

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

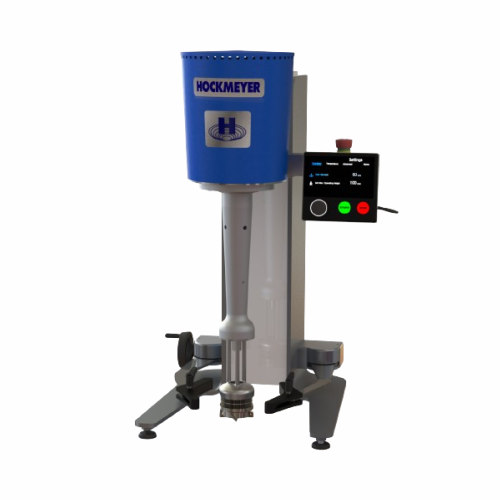

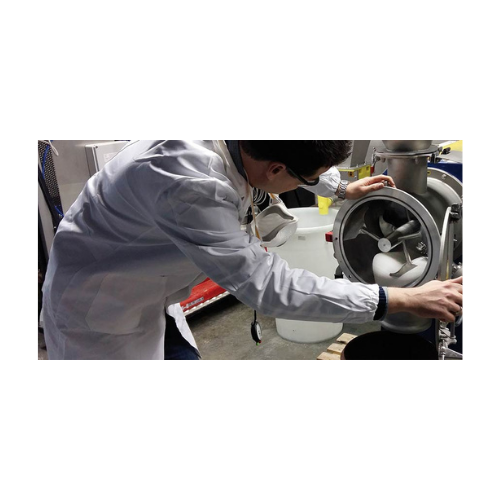

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for...

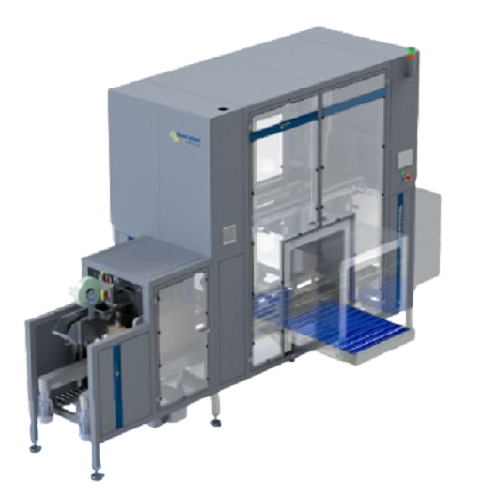

Integrated packaging system for valve and Ffs bags

Streamline your packaging operations with a versatile system designed ...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

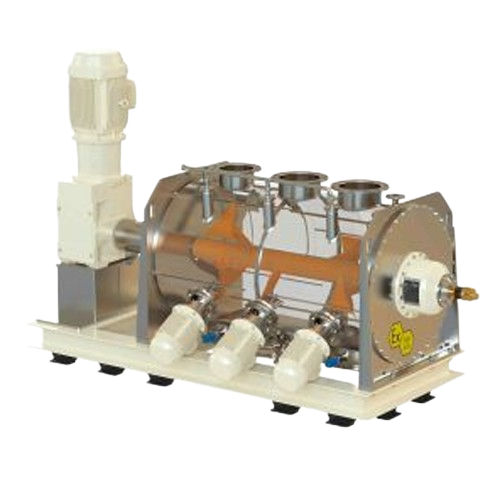

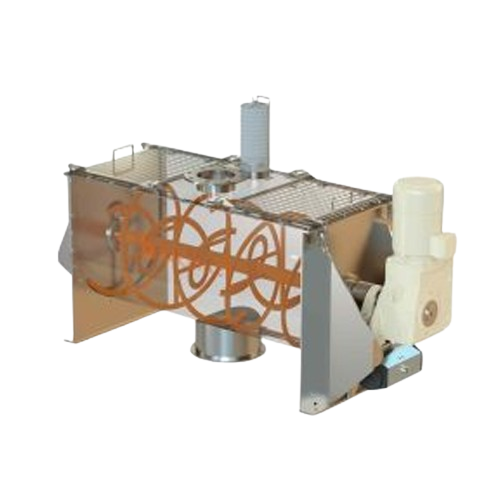

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Medium to large-size box making line

Streamline your packaging process with a versatile box making line that efficiently ha...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Product counting system for confectionery and food products

Achieve 100% counting accuracy and seamless integration in y...

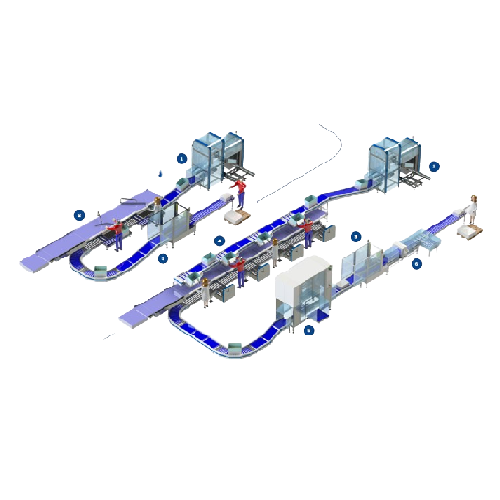

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

Planetary mixer for homogeneous material mixing

Achieve precise and consistent mixing of diverse materials from powders to...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

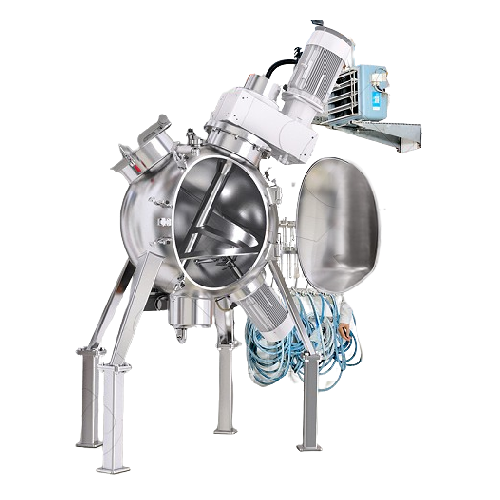

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

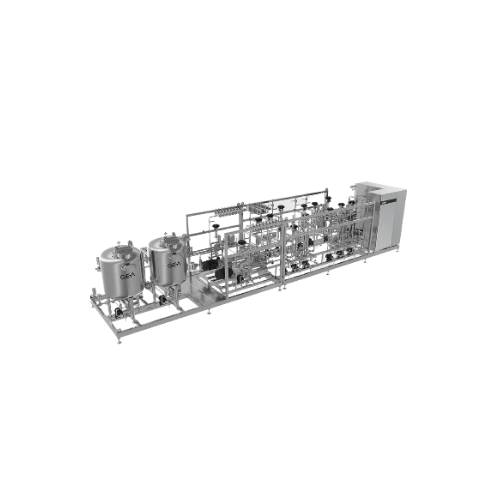

Ultrafiltration and microfiltration test unit

Streamline your filtration and membrane testing with a flexible, scalable un...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

Rotary volumetric filling solution for viscous products

Achieve precision in volumetric filling with a machine designed f...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Indexed stomp capper for continuous bottle capping

Solve the challenge of manual snap cap placement with a seamless, cont...

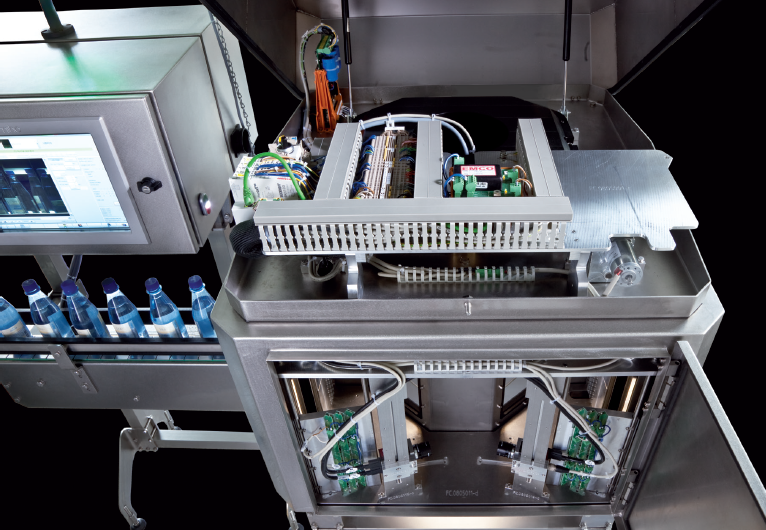

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Continuous in-line blender for home and personal care products

Achieve precision and flexibility in blending liquid mult...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Pure steam generator for industrial applications

Ensure the highest levels of steam purity and precise pressure control fo...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

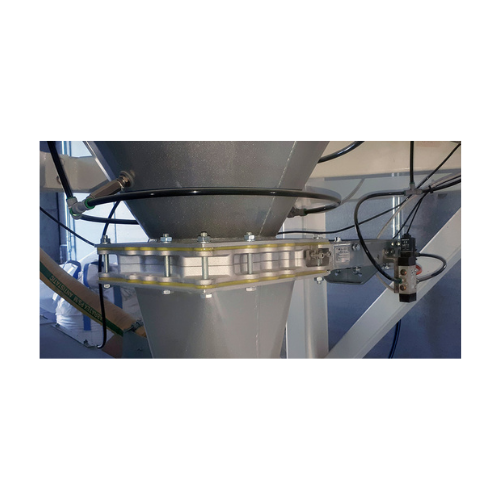

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Industrial slide valve for heavy-duty applications

When managing gravity material flow in abrasive environments, achievin...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

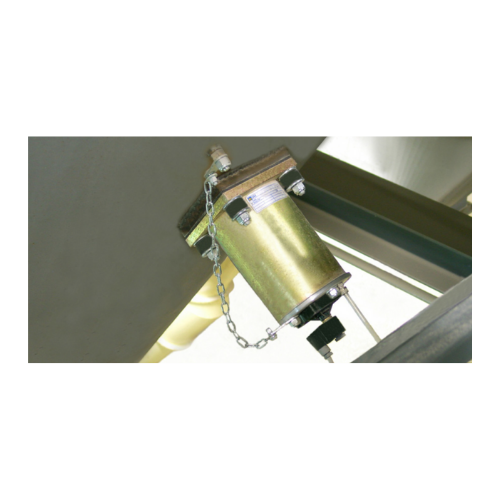

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Lump breaking feeder valve for bulk material processing

Tackle bulk material flow challenges with a feeder valve engineer...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

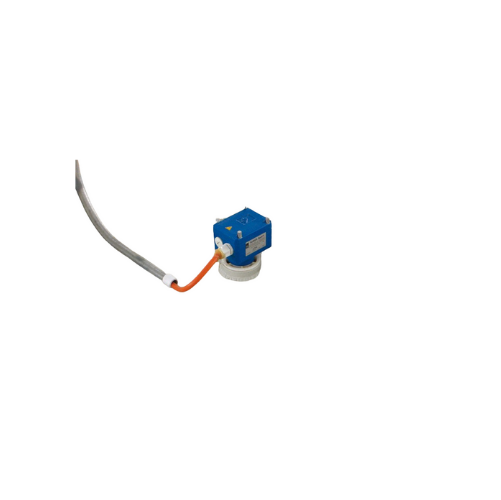

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Vertical conveyor for fine aggregates and minerals

Optimize the handling of abrasive materials with a vertical conveying ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Horizontal stand-up pouching system for liquids and solids

For producers aiming to optimize efficiency and precision, th...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

Adjustable integral stand mixer for transport containers

Achieve optimal mixing and stirring in diverse transport contain...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

In-line mixer for liquid-liquid and solid-liquid processes

Optimize your mixing operations with an efficient solution th...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

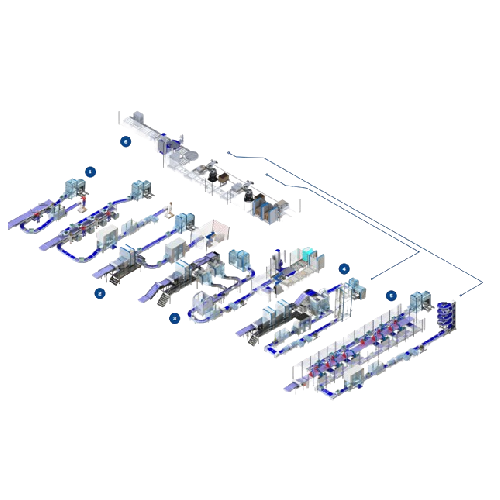

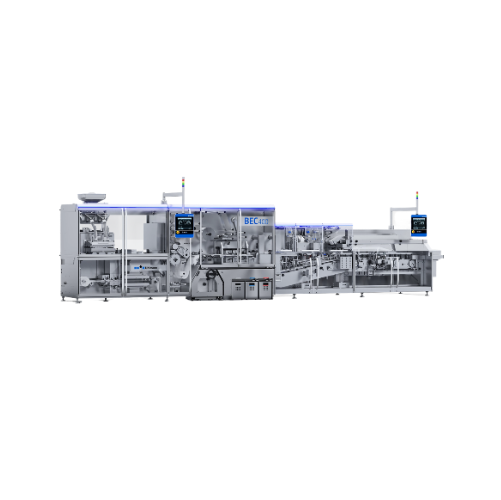

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

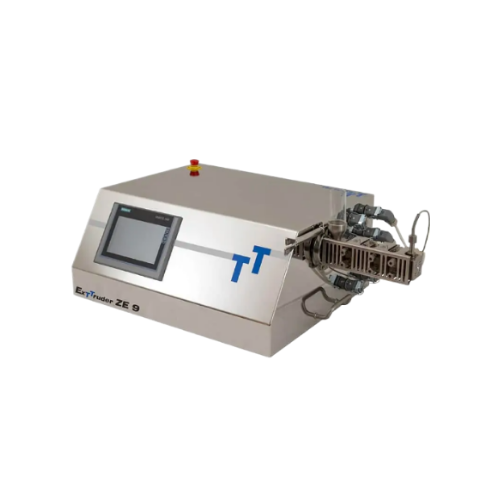

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

Volumetric twin screw feeder for powder and micro-granules

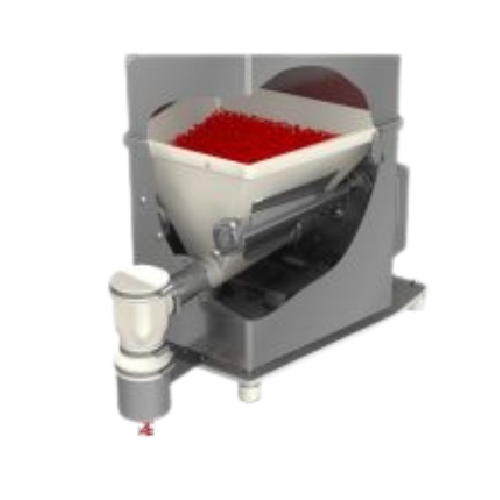

Optimize your production flow by ensuring consistent and prec...

Twin screw feeder for poorly flowing powders

Optimize your process with precision feeding for powders that easily clump or...

Twin screw feeder for bulk material handling

Optimize your bulk material processing with a solution designed for precise f...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Volumetric flat-bottom twin-screw feeder for powders

When handling powders prone to clumping, a reliable feeder ensures u...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Volumetric single-screw feeders for free-flowing products

Achieve precise and continuous feeding of free-flowing powders...

Volumetric single-screw feeder for free-flowing products

Optimize your production line with precise feeding and metering ...

Hot cutter for processing extrudate into pellets

Efficiently transform extrudates into precise pellet sizes, enhancing you...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

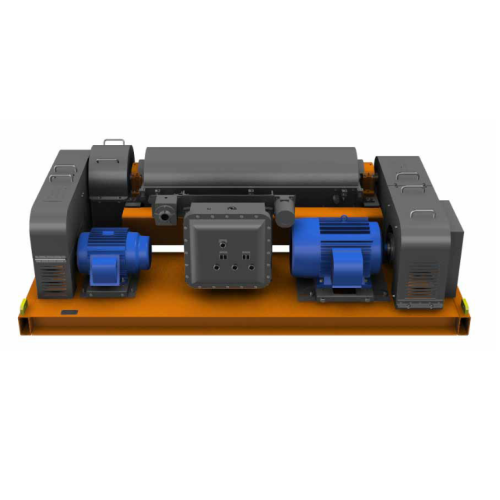

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Multi-motion rectangular separator

Solve screen blinding effortlessly with an innovative system that combines elliptical an...

Universal motion rectangular separator for pulp and paper

Achieve precise motion adjustments with a versatile separator ...

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Centrifugal sifter for efficient particle separation

Enhance your material throughput by efficiently separating particles...

Drying and cooling classifier for plastic pellets

This solution enhances efficiency by combining drying, cooling, and cla...

Lab scale round separator for particle classification

Optimize lab-scale processes with this compact separator, ideal for...

Low profile flow-thru separator for wet or dry scalping

Efficiently handle high-capacity separation with a compact design...

Quickchange systems for vibratory separator screen changes

Streamline your production with a system that enables rapid s...

Vibratory separator for efficient solid-liquid separation

Maximize throughput and efficiency in your production line wit...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Ultrasonic round vibratory separator for fine powders

Efficiently prevent screen blinding during powder separation proces...

Dual-motion rectangular separator for pulp and paper industry

Optimize your production line with a versatile separation ...

Accu-feed system for dry material separation

Boost efficiency by combining storage, feeding, and screening into one space-...

Round vibratory separation for high capacity screening

Maximize screening efficiency with dual screen vibratory technolog...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Round vibratory separation for various industrial applications

Ensure accurate material separation with a robust solutio...

Sub-micron particle size reduction grinding mill

Achieve precise particle size reduction effortlessly with advanced vibrat...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Spray bed dryer for agglomerated powder production

Efficiently transform liquid feedstock into consistent, dust-free powd...

Bin activator for reliable bulk solids discharge

Ensure reliable flow and prevent compaction in your production line with ...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line ...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Feeder controller for gravimetric feeders

Optimize your dosing precision and monitoring accuracy with a versatile feeder c...

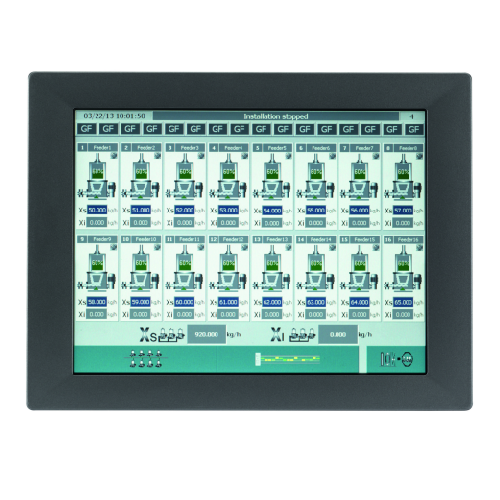

Gravimetric feeder operator interface

Efficiently manage up to 16 gravimetric feeders with a user-friendly interface, enabl...

Single feeder operator interface for gravimetric feeders

Enhance precision in your dosing operations with an intuitive to...

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Batch feeder for bulk solids processing

Achieve precise batch dosing with this advanced feeder, designed to handle a variet...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

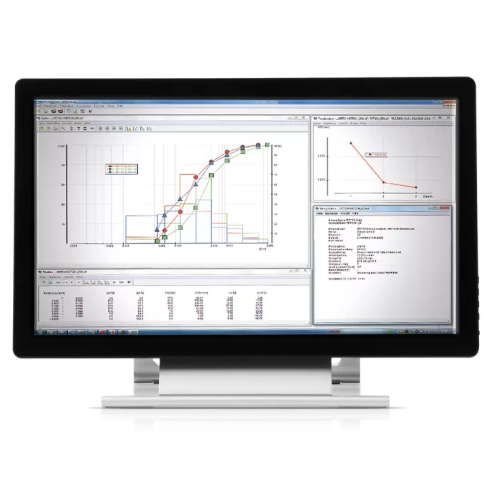

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

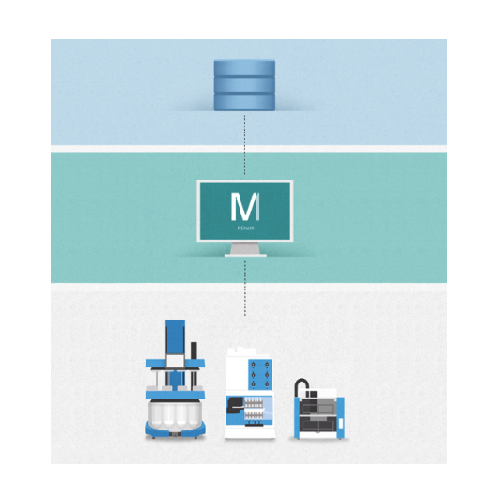

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

Versatile rotary filler-capper for liquid products

Optimize your liquid product production with a versatile solution that...

Pet bottle production for small and medium outputs

Optimize your production line by manufacturing PET bottles in-house, r...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Injected density stabilizer for pneumatic conveying

Optimize your dense phase pneumatic conveying with a stabilizer desig...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Infrared moisture analyzer for lab and production use

Achieve precise and reliable moisture analysis with minimal time an...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Tray packer for forming, loading, and sealing

Optimize your production line with a versatile tray packer designed to seaml...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

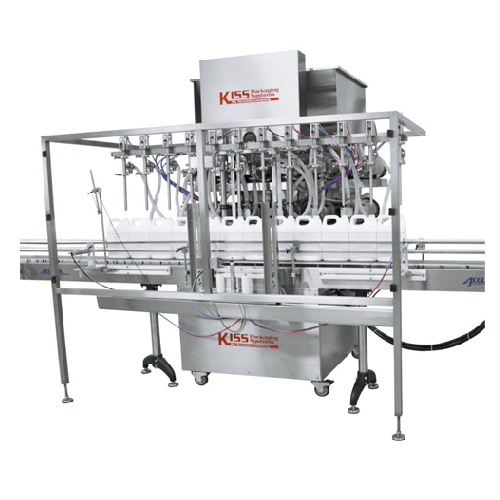

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

Magnetic agitator

Reliable mixing and agitation are essential to any quality production process that involves a fluid. This n...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

Palletizing robot arm

For high speed palletizing, palletizing high payloads, or just where greater flexibility is required, i...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....