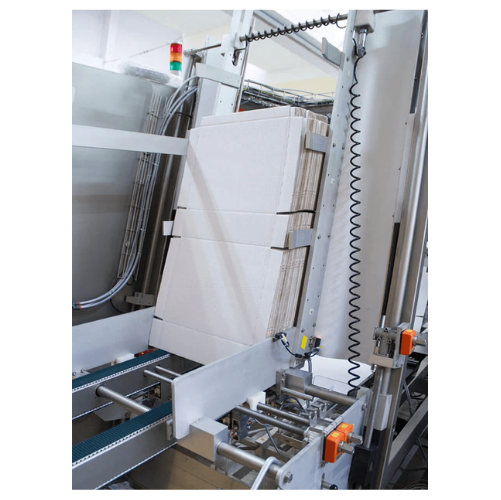

Automated wrap-around packaging system

Streamline your packaging process with a system that efficiently groups, folds, and glues corrugated board into cases or trays, ensuring precision and consistency in every package.

Groups and Packs Products into Cases and Trays

The 710 Series from Trepko is a fully automatic wrap-around case packer tailored for high-speed, continuous operation in food and beverage manufacturing and packaging industries. It excels in efficiently grouping and packing products such as cereal boxes, beverage cartons, and pharmaceutical cartons into cases or trays. Utilizing flexible modular components, it allows quick adjustments for varying product dimensions and packaging patterns, ensuring seamless integration into existing production lines. With a maximum output of 20 cases per minute, its interchangeable blank feeders facilitate rapid changeovers, minimizing downtime. The machine’s advanced drive systems enhance reliability, while offering precision in forming and gluing, contributing to reduced maintenance costs and extended service life. Additionally, the 710 Series is equipped to handle multiple ‘blank’ stacks for uninterrupted long runs, making it an indispensable tool for optimizing packaging operations.

Benefits

- Enhances production efficiency with up to 20 cases per minute throughput.

- Reduces changeover time with quick-access interchangeable blank feeders.

- Minimizes maintenance costs through durable construction and modern drive systems.

- Accommodates diverse packaging needs with flexible case and tray format options.

- Extends operational runs with capability for multiple blank stack loading.

- Applications

- Cases, Boxed goods, Packaged products, Trays, Corrugated board packaging

- End products

- Dairy product cartons, Household item packages, Detergent boxes, Electronic goods packaging, Personal care product boxes, Pharmaceutical cartons, Cereal boxes, Baked goods packaging, Snack trays, Beverage cartons

- Steps before

- Grouping, Arranging products

- Steps after

- Distribution, Shipping

- Input ingredients

- flat sheet of corrugated board, 'blank' feeders, pre-arranged products

- Output ingredients

- cases, trays, packaged boxes

- Market info

- Maximum output speed

- 20 cases/minute

- Box dimension (min)

- 200x105x70 mm

- Box dimension (max)

- 600x240x350 mm

- Power

- 17 kVa

- Control/Pilot system

- 24 V

- Machine weight

- 1300 kg

- Air pressure

- 6 bar

- Air consumption

- 600 l/min

- Automation level

- Fully automatic

- Changeover time

- Quick and easy

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- High efficiency

- Compatibility with corrugated board

- Yes

- Cleanability

- Easy maintenance

- Versatility in packing various materials

- High

- Corrosive resistance

- Modern materials used

- Compact footprint

- Yes

- Machine weight

- 1300 kg

- Box dimension range

- min. 200x105x70 max. 600x240x350

- Output speed

- 20 boxes/min

- Air pressure

- 6 bar

- Air consumption

- 600 l/min

- Power requirements

- 17 kVa

- Control system

- 24 V

- Pack types and sizes flexibility

- Multiple pack sizes and types

- Changeover procedure

- Quick and easy

- Interchangeable blank feeders

- Allows different case/tray sizes

- Future additions capability

- Expandable

- Blank stack loading capacity

- Multiple blank stacks for extended runs