Spot welding robot for confined spaces

Optimize spot welding efficiency in tight manufacturing spaces with a compact robot designed for high accessibility and minimal maintenance, ensuring seamless integration into your production line.

Performs Spot Welding and Foundry Tasks

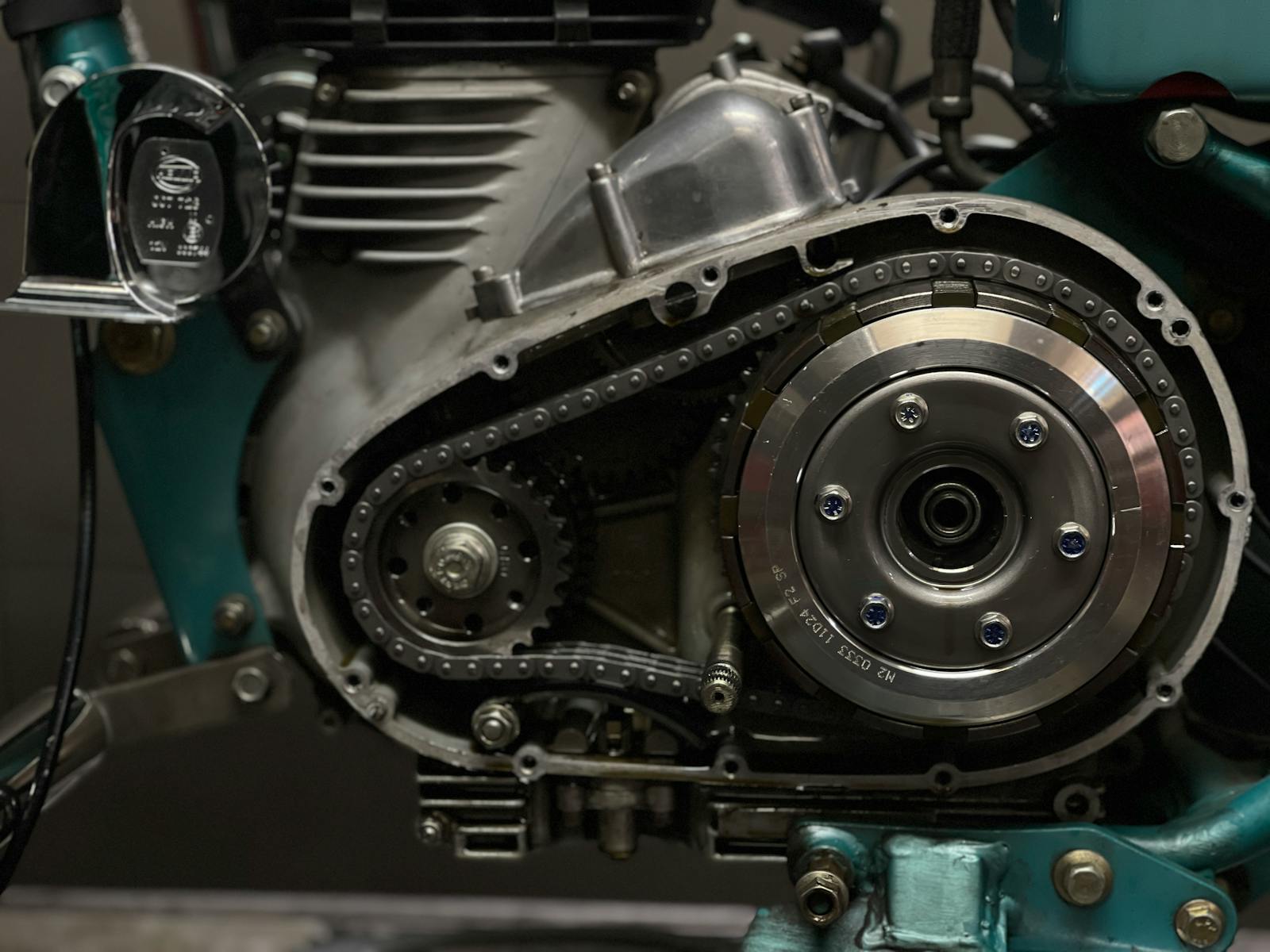

The KR QUANTEC Nano from KUKA is a versatile industrial robot designed for seamless automation in challenging environments, including automotive and foundry sectors. It stands out for its compact design, allowing for superb accessibility in tight spaces, crucial for applications such as spot welding and cleaning in medium to large washing cells. With load capacities ranging from 120 kg to 180 kg, it maneuvers with precision thanks to its optimized, virtually wear-free drive train, ensuring long-term, low-maintenance performance. The robot integrates easily into production lines, equipped with protection ratings up to IP 69, safeguarding against dust and high-pressure water jets—ideal for critical tasks in cleaning systems and foundries. Its energy efficiency is enhanced by lightweight construction using cast iron for increased robustness, enabling dynamic operations without requiring counterbalancing systems. KUKA offers extensive customization options and engineering support to tailor the KR QUANTEC Nano to specific production needs, ensuring compliance with stringent industry standards.

Benefits

- Enhances production efficiency with precise spot welding and high-stress handling capabilities.

- Saves space and improves process integration with its compact design.

- Minimizes maintenance requirements with its virtually wear-free drive system.

- Ensures operator safety and equipment longevity with high-level protection ratings (up to IP 69).

- Increases operational flexibility with customizable options and dedicated engineering support.

- Applications

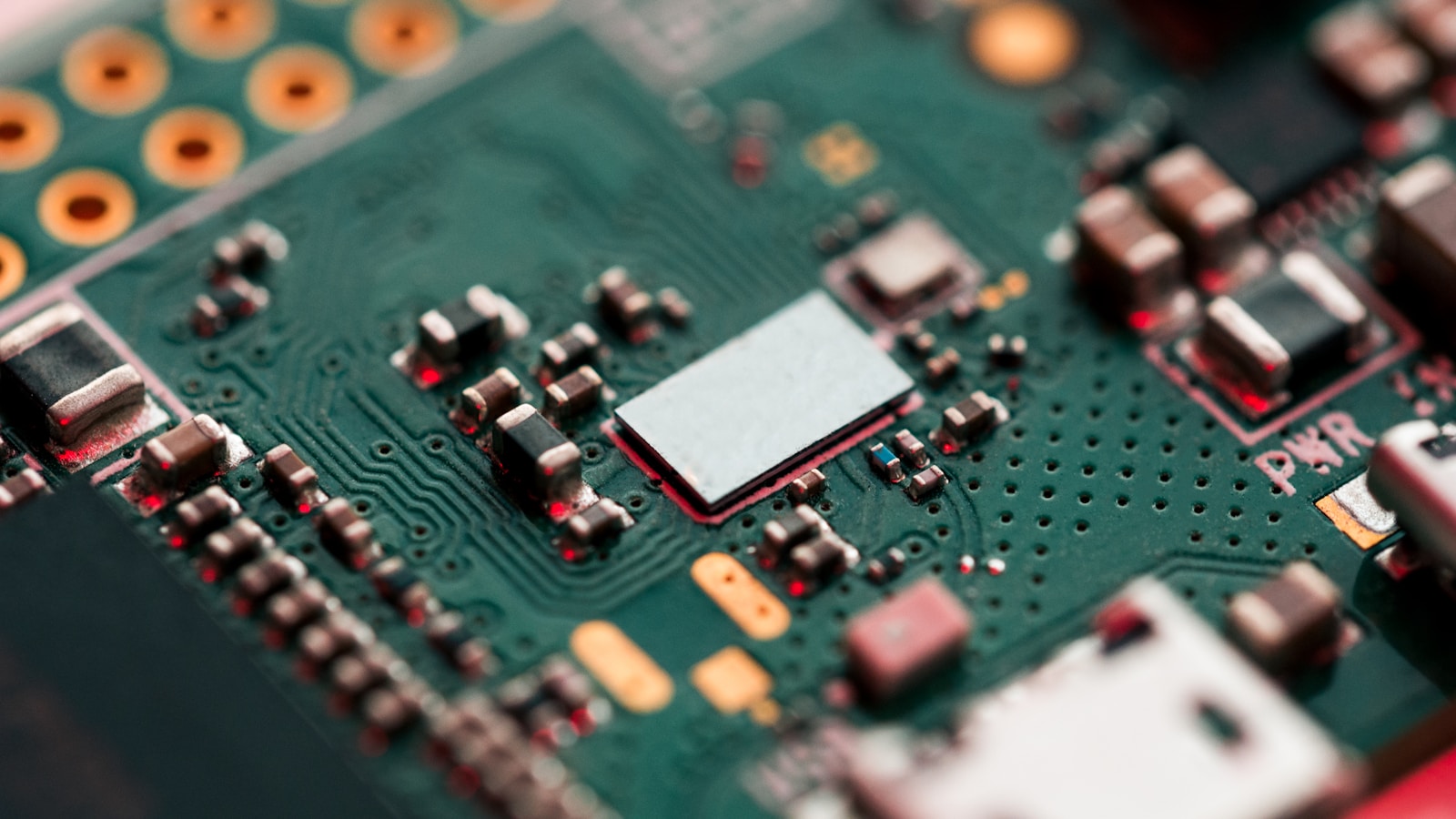

- Foundry products, Detergents, Automotive components, Engine components, Consumer goods, Electronic parts, Cleaning systems, Batteries, Metal products

- End products

- Washing machine parts, Circuit boards, Aluminum castings, Lithium-ion batteries, Fabric softener sachets, Engine block castings, Plastic toys, Car body panels, Metal brackets

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Load capacity

- 120 - 180 kg

- Maximum reach

- 1573 - 2100 mm

- Protection class

- IP 65, IP 67, IP 69

- Mounting positions

- Floor / Ceiling

- Drive train

- Virtually wear-free

- Working Envelope

- Large with rear swing over Axis 3

- Accessibility

- Good in confined spaces

- Space-Saving Design

- Streamlined

- Automation Level

- Yes

- Maintenance Requirement

- Low

- Protection Ratings

- IP 65, IP 67, IP 69

- Dynamic Properties

- Outstanding

- Adaptability

- Tip dressing, Spot welding, Parts cleaning

- Environmental Suitability

- Foundry exclusive

- Mounting Positions

- Floor/Ceiling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Suitable applications

- Spot welding, cleaning, washing

- IP certification

- IP 65, IP 67, IP 69

- Machine weight

- Lightest in its class

- Footprint design

- Space-saving, streamlined

- Reach

- 1573 - 2100 mm

- Load capacity

- 120 - 180 kg

- Construction type

- Standard

- Mounting position

- Floor/Ceiling

- Protection class

- IP 65, IP 67, IP 69

- Integration possibilities

- PLC / SCADA

- Mounting positions

- Floor / Ceiling