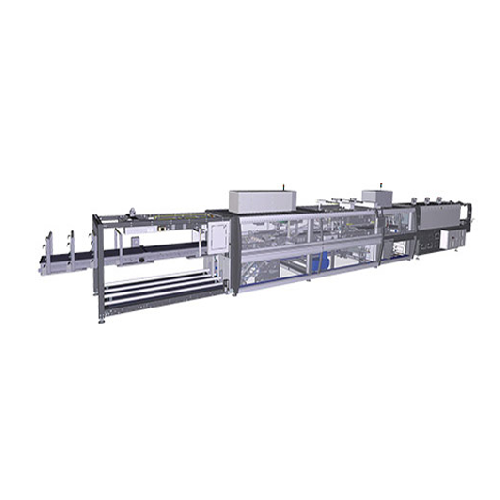

Combined packers with in-line infeed for plastic and glass containers

Streamline your packaging process with a versatile solution that expertly combines wrap-around packing and shrink wrapping, ensuring efficient handling of various container types and configurations to optimize throughput and reduce downtime.

Packs, Wraps, and Shrink Wraps Multi-Container Formats

The LCM ERGON Series from SMI integrates the capabilities of wrap-around packers and shrink wrappers in a single unit, adept at packaging diverse containers like plastic, metal, cardboard, and glass. This series excels with versatile configurations for varying product sizes, supporting setups like 2×3 and 3×4 arrangements. Achieving speeds of up to 40 packs per minute, the machines feature a mechanical product-grouping system with a choice between in-line or 90° in-feed conveyor setups. Designed for operational efficiency, these machines boast energy-saving ICOS brushless motors, and the absence of gearboxes reduces maintenance and noise. The LCM ERGON’s modular design allows for seamless integration into existing production lines, complemented by a user-friendly POSYC® control panel. Added features like motorized film cutting, electronic tensioning, and robust hot-glue sealing ensure durable, precisely wrapped packages, making it ideal for industries such as beverage, food, and consumer goods manufacturing.

Benefits

- Boosts packaging efficiency with speeds up to 40 packs per minute.

- Lowers maintenance requirements through direct motor-to-shaft connections, eliminating gearboxes.

- Enhances operator safety and accessibility with rounded, easy-to-open safety doors.

- Ensures environmental compliance and energy efficiency via optimized shrink tunnel technology.

- Offers flexible packaging solutions for various container types and configurations, adapting to current and future needs.

- Applications

- Bottled beverages, Consumer packaged goods, Detergents, Household products, Industrial products, Glass containers, Plastic containers, Cardboard containers, Packaged foods, Metal containers

- End products

- Cardboard juice cartons, Consumer cosmetic bottles, Household cleaner bottles, Pet water bottles, Bottled soft drinks, Glass beer bottles, Packaged snacks, Lubricant oil bottles, Aluminum soda cans, Detergent bottles

- Steps before

- Container sorting, Product grouping, Container alignment

- Steps after

- Shrink wrapping, Case sealing, Quality inspection, Palletizing

- Input ingredients

- plastic containers, metal containers, cardboard containers, glass containers, loose containers, corrugated cardboard blanks

- Output ingredients

- wrap-around case packs, tray + film packs, tray only packs, closed case packs, shrink-wrapped packs

- Market info

- SMI Group is known for designing and manufacturing innovative packaging machinery and bottling plants. They provide cutting-edge solutions for ETO equipment, emphasizing flexibility, reliability, and efficiency in serving industries like food, beverage, and consumer goods.

- Speed

- up to 40 packs per minute

- Packaging Type

- Tray + film, Tray only, Wrap-around case, Wrap-around tray

- Infeed Type

- In-line or 90° infeed

- Pack Collations

- 2x3, 3x4, 4x6 in closed boxes

- 4x3,6x4 on tray+film

- Film Tensioning

- Progressive brake system with constant tensioning

- Film Cutting

- Electronic adjustment

- Shrink Tunnel

- Heat-shrinking tunnel with forced air ventilation

- Motor Type

- ICOS brushless motors with digital servo-driver

- User Interface

- Interactive 15'' touchscreen display and operator panel

- Modular Design

- Interchangeable mechanical and electronic components

- Construction Material

- Sand-blasted and powder-painted steel, anodised aluminium doors

- Control System

- POSYC control panel with diagnostic functions

- Packaging speed

- up to 40 packs per minute

- Product grouping system

- Mechanical

- Infeed options

- In-line or 90° in-feed

- Changeover process

- Manual

- Film tensioning

- Progressive brake, constant tensioning

- Automation level

- Control via interactive touchscreen display

- Energy consumption

- Low energy motors

- Maintenance

- Easy and cost-saving

- User interface

- POSYC® touchscreen control panel

- Corrosive resistance

- Acids

- Density/particle size

- Wide range

- Container type

- Plastic / Metal / Cardboard / Glass

- Infeed type

- In-line or 90° in-feed conveyor belts

- Interactive control

- 15'' touchscreen display

- Machine Footprint

- Compact

- In-feed Method

- In-line or 90° infeed

- Pack Configuration

- Wrap-around case, Tray+Film

- Film Unwinding System

- Progressive brake, constant tensioning

- Cardboard Magazine Position

- Beneath in-feed conveyor

- Material of Protection Doors

- Anodised Aluminium

- Pack Format

- 2x3, 3x4, 4x6

- Motor Placement

- External

- Machine Frame Material

- Sand-blasted and powder-painted steel

- Touchscreen Display

- 15" Interactive

- Sliding Protection Doors Design

- Rounded shape with slow-down device

- Pneumatic/Electronic Device

- Product grouping

- Blade Type

- Motorized film-cutting knife

- Control panel type

- Interactive 15'' touchscreen display

- Customization of packaging formats

- 2x3, 3x4, 4x6 closed boxes

- 4x3,6x4 tray+film

- Integration possibilities

- Motorized system of oscillating laning guides

- Safety features

- Sliding protection doors with slow-down device

- Film tensioning control

- Electronic adjustment with tensioning spring

- Door type

- Sliding protection doors in anodised aluminium

- Motor type

- Brushless motors with digital servo-driver

- Pack collation options

- Multiple configurations based on container shape and size

- Connectivity and interfaces

- POSYC® control panel with intuitive interface

- Machine frame material

- Sand-blasted and powder-painted steel