Cream Homogenizing Equipment

Find production technology for homogenizing creams, and connect directly with leading machine manufacturers worldwide.

When making creams, manufacturers need to mix water and oil-soluble ingredients that are two mutually immiscible liquids. But how do you bring together two things that are basically incompatible with each other? Homogenization will deal with it. Cream homogenization involves a vigorous mixing action to reduce the particle sizes of the mixture in order to create a uniform and stable cream. With the help of homogenizing systems such as a high-shear homogenizer or high-pressure homogenizer, you can form a stable emulsion and reach the viscosity and consistency you desire.

Which cream homogenizing technology do you need?

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

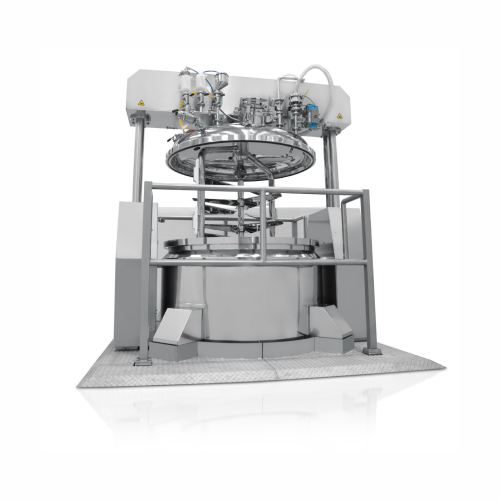

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

Undervacuum homogenizer for cosmetic and pharmaceutical creams

Optimizing the production of creams and lotions, this und...

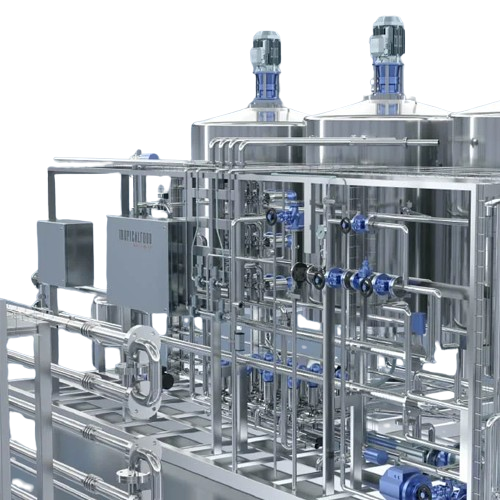

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Compact milk pasteurizer for milk, cream, and whey

Ensure consistent product quality with precise pasteurization and skim...

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Dairy pasteurization system for milk, yoghurt, and cream

Ensure reliable dairy processing with an advanced pasteurization...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

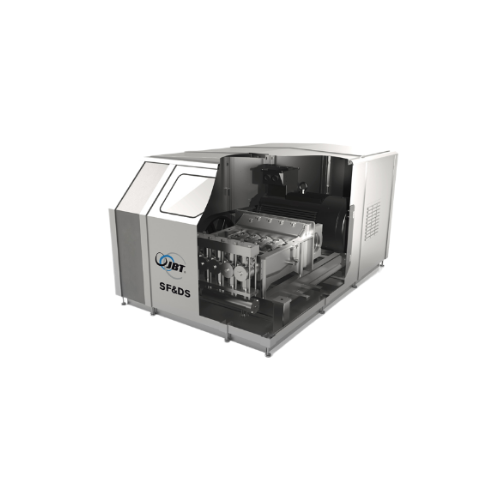

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Homogenizer for creams

Homogenization (or pharmaceutical micronization) is the process of reducing particle sizes, and is a v...

Flexible mixing system for whipped cream and pastries

Delicacies such as meringue, ganache, and marzipan undergo various ...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

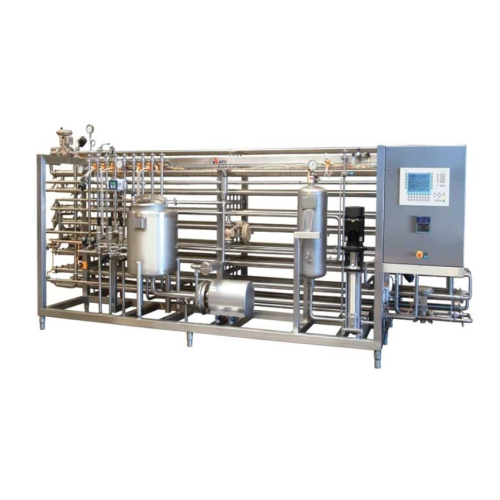

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Homogenizer for dairy products

Achieve precise texture and quality in dairy products with this versatile homogenizer, design...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

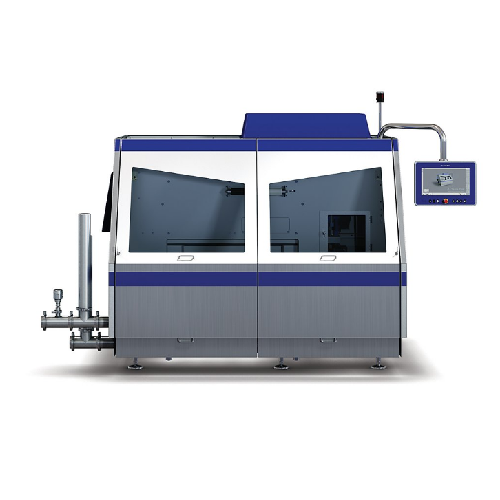

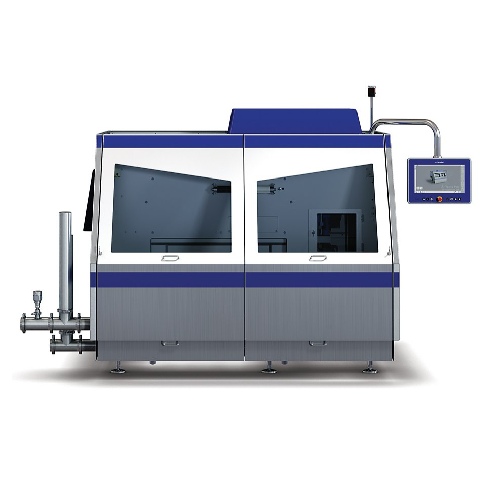

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Industrial homogenizer for Uht sterilization systems

Achieve smoother product consistency with high-pressure homogenizati...

Small-scale milk pasteurizer with skimming centrifuge

Quickly integrate a versatile pasteurization system into your produ...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Dry and liquid ingredient batch mixer for bakery applications

Achieve homogeneous mixing with precise heat control and e...

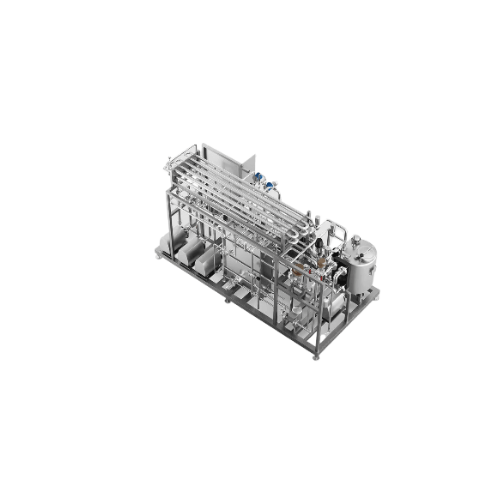

Tubular Uht processing for dairy products

Experience efficient high-pressure thermal processing with tubular UHT technolog...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

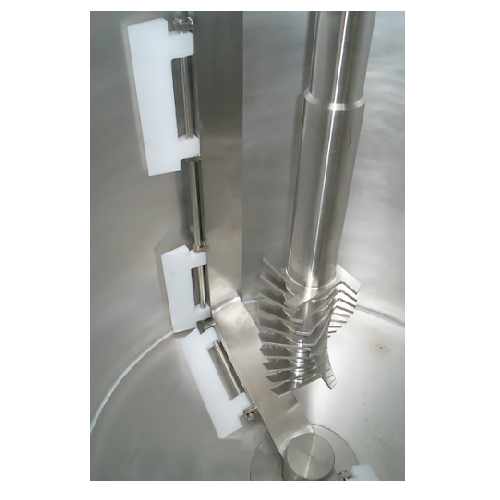

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Direct Uht processing for heat-sensitive liquid products

Achieve optimal taste and nutritional value in liquid foods thro...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

Multipurpose ultra high temperature (uht) pilot plants

Optimize liquid food production with a versatile pilot unit design...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

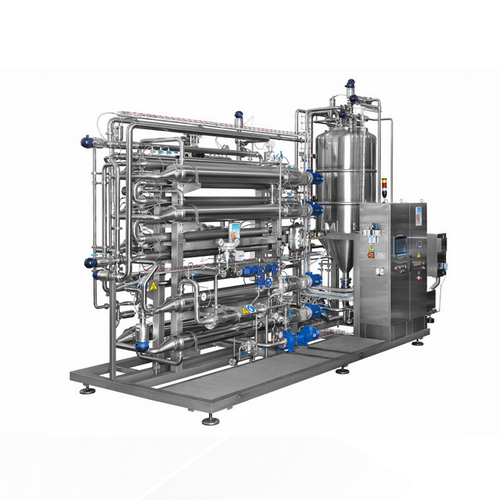

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...