Making Flax Seeds

Find innovative production technology for making flax seeds and connect directly with world-leading specialists

You process flax seeds to produce linseed oil, which is used as a preservative finish for wooden materials like varnishes or paints. People also consume flax seeds as a whole seed or ground. Flax seeds production goes through drying, de-hulling or milling, and separation processes to extract the kernels, which are cleaned and ready for consumption. For oil extraction of seeds, you need to further process the kernels by pressing and refining.

Select your flax seeds process

Tell us about your production challenge

Chew it whole or grind and mix

Flax seeds are a variety of seed that comes from the Flax plant. The flax seeds are processed into many forms for food consumption. To get whole flax seeds, dry the flax plants and de-hull the shell that contains the flax seeds or kernels. Then separate the seeds from impurities and clean them. Next step is to either pack them for consumption or process them further to produce ground flaxseed and flaxseed oil. You produce ground flax seeds by milling the whole seeds. Between the whole and the ground flax seed, the latter provides better health benefits since our bodies cannot easily digest whole flax seeds. They can, on the other hand, easily absorb the nutrients from the ground flax seeds, such as omega 3 oil and antioxidants.

Most health-conscious consumers prefer to purchase whole seeds and ground them using a food processor to make sure they know exactly what they are eating. Ground flax seed may also go rancid if exposed to air at room temperature for a week.

Flax seed oil on an industrial scale

Flax seeds contain about 40 to 45% oil, also known as linseed oil. It is primarily used in industrial applications such as paints, varnishes, resins, and inks due to its drying properties. There are two methods of extracting oil from flax seed: cold press and hot press. Cold press only requires a mechanical press to extract the oil and filters to remove impurities. For hot press method, you heat the seeds and press them to extract the oil. Then, you process the cake further by adding a solvent to extract more oil. After that, you remove the solvents by distillation.

The oil undergoes degumming process before adding sodium hydroxide; then a centrifuge separates more impurities. After a bleaching process, to give a clear appearance before cooling it at a very low temperature to remove the wax, the oil goes through filtration, and the final product is refined linseed oil.

Environmental impact of flax seeds

Flax seed production is sustainable and does not have negative impacts on the environment. The flax fibers from the stem of the plant can be used to produce linen, and the seeds can be processed to produce food and oil. Growing flax seeds has moderate water footprint and little carbon footprint. It leaves no damage to air, water, soil, and other wildlife as long as pesticides and fungicides are well-controlled.

Processing steps involved in flax seeds making

Which flax seeds technology do you need?

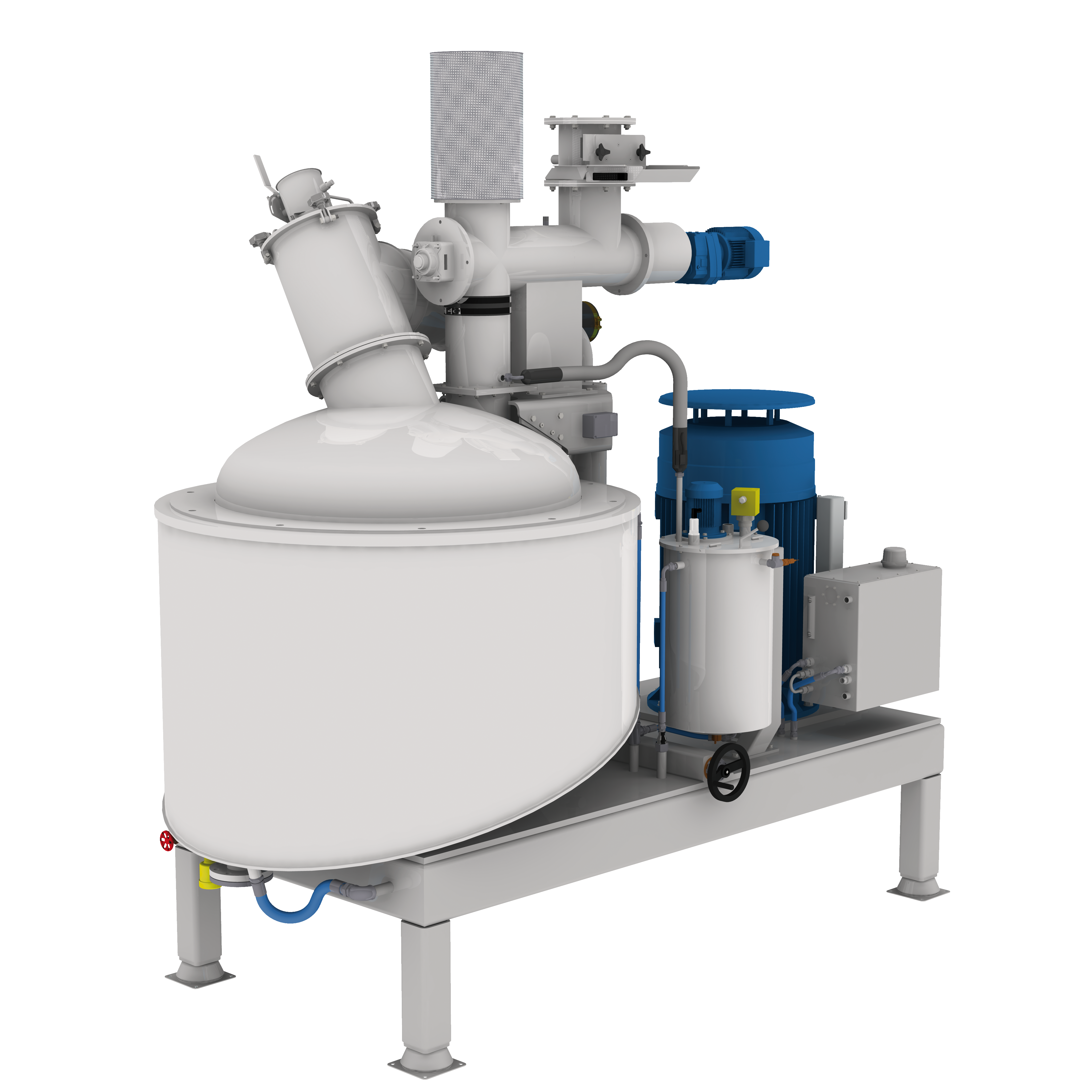

Exergy pressurized superheated steam dryer

Traditional dryers and heat transfer systems, like belt-, drum- or bed dryers a...

Cocoa liquor grinding line

After roasting and cracking chocolate beans (without husks), the following process is the grindin...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

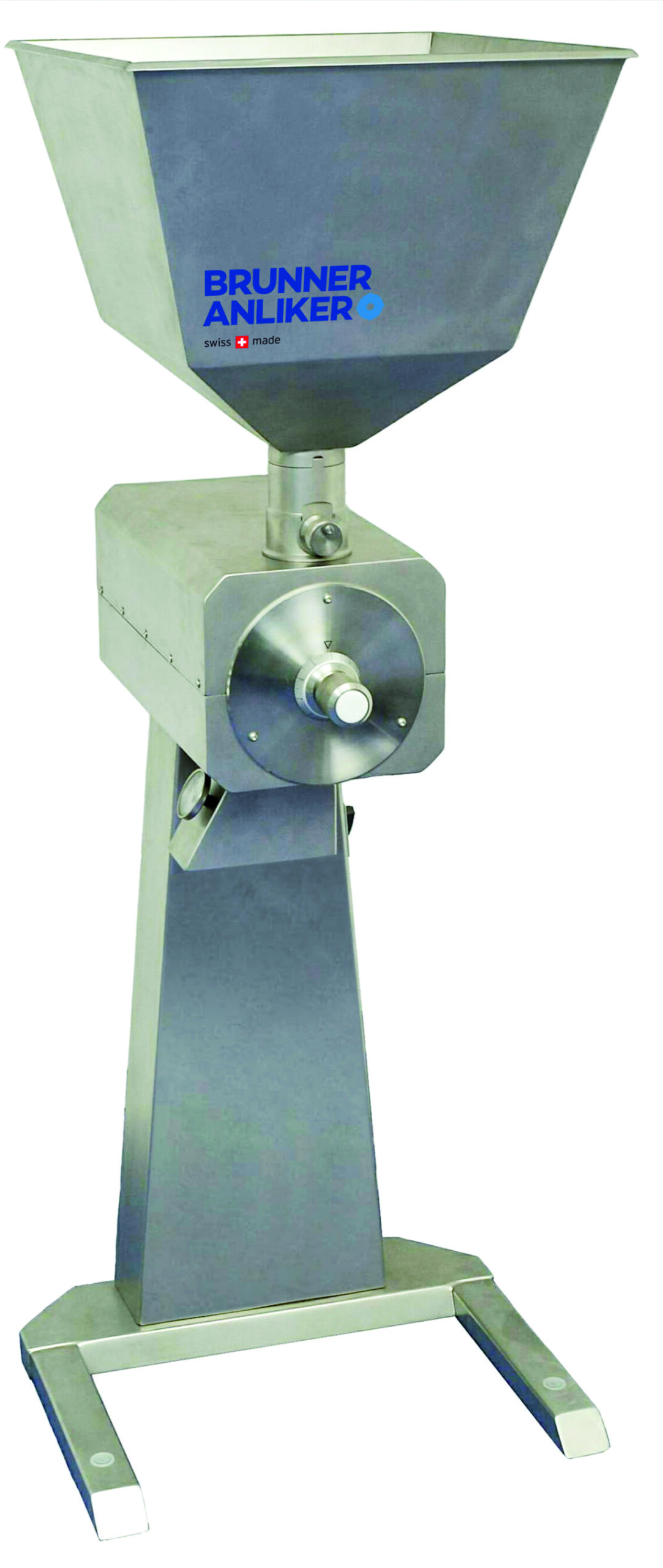

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...