Making Paints

Find innovative production technology for making paint and connect directly with world-leading specialists

Painting as an integral aspect of the human tradition dates to thousand years ago. Of the many properties of the product, the drying time is important to consumers. The thickness of the paint and environmental factors like humidity affect this parameter. Paint manufacturing equipment must include a humidity test chamber to assess the behavior of paint under different weather conditions.

Stories about paint

Tell us about your production challenge

Water-based paints versus oil-based paints

Years ago, nearly all available paints were oil-based, but today consumers have the option of a water-based coating. In the process of paint manufacturing, the solvent determines the paint type. Oil-based paints contain oil as their solvent, while water-based paints use mainly water. Oil- or solvent-based paints have a much higher level of organic compounds than their counterpart. These compounds enhance their application, drying time, and durability. However, they release strong odor and toxic volatile organic compounds that negatively impact the environment.

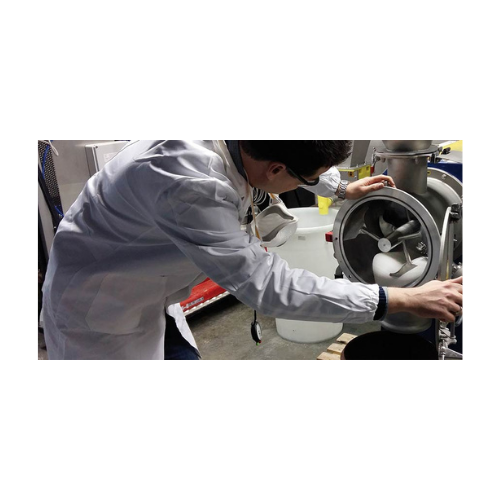

Recently, technological advancements have led to the manufacture of water-based paints that have excellent drying time with far less odor. The common paint manufacturing equipment used for both include mixers, mills, and filters.

Mixers are important for solid-liquid mixing. Mills are used to damage any coagulated particles while filters purify the paint. The choice between both depends on what you want to achieve. Generally, water-based paints retain their colors for a long time and are better for outdoor painting, while rust-resistant oil-based paints go better with moldings and trims.

The impact of Volatile Organic Compounds on the environment

As paints dry, they release Volatile Organic Compounds (VOC), chemical compounds that evaporate at room temperature. When they do it, they negatively impact human health and the environment. Once they are in the air, they play significant roles in forming ozone. These compounds also trigger conditions like allergies, asthmatic reactions, and skin and eyes inflammation.

Water-based paints solve these concerns because they don’t contain organic compounds. As a regulatory measure, the European Union has published a test standard that uniformly controls the emission rate from products. This authorizes manufacturers to test and indicate emission measurements from their products.

Standard tests made from paint manufacturing equipment

Paint manufacturers must ensure the solvent they use aligns with quality control standards. They do this by testing various parameters. Some of these tests include a density test which checks if the solvent is mixed with other components or not. A pigment test helps to know the amount of binder and resin required to absorb a specific amount of pigment. A fineness test checks how smooth painted surfaces will be, while the gloss test determines the degree of shine for the paint. Other tests are washability and impact resistance. They ascertain the paint’s resistance to washing and measure the film’s resistance against hard shocks, respectively.

Application of paints, defined by their constituents

End-products from a paint manufacturing machine differ in their application depending on their constituents. Oil-based coatings are tougher than water-based paints and are used for residential furniture, metal railings, and industrial steel equipment.

Enamel additive makes the dried surface harder and less porous. Most water-based flooring paints contain enamel additives.

Urethane additives offer superior water and abrasion resistance and are common in industrial coatings, where durability is of utmost importance. Epoxy coatings are easy to apply, dry quickly, and form protective coatings. You can apply them to concrete and steel to offer resistance to water, alkali, and acids.

Processing steps involved in paint making

Which paint technology do you need?

Laboratory drum mill for large sample volumes

Efficiently process large volumes of diverse materials into precise particle...

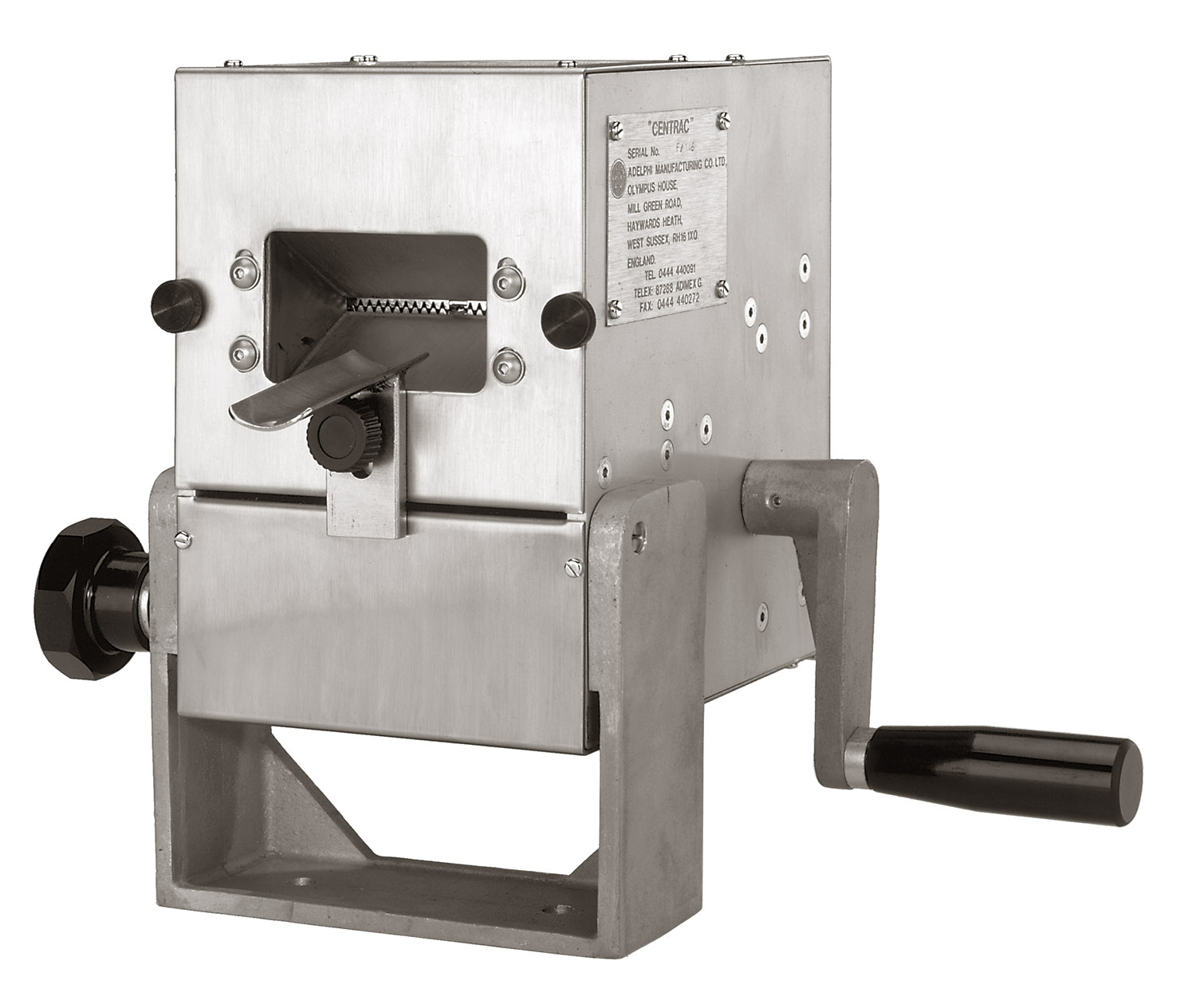

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

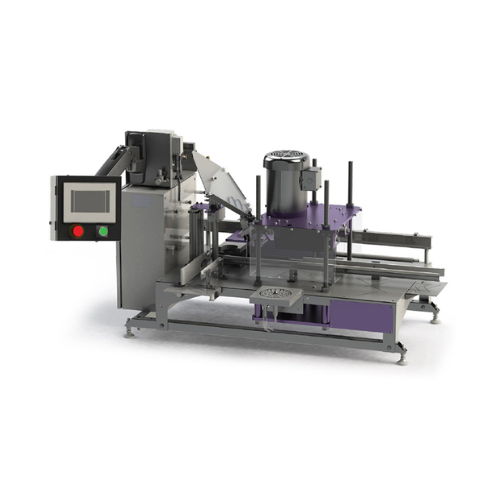

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

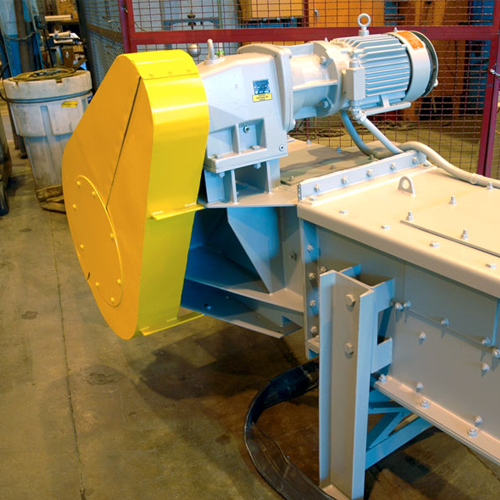

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while ...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

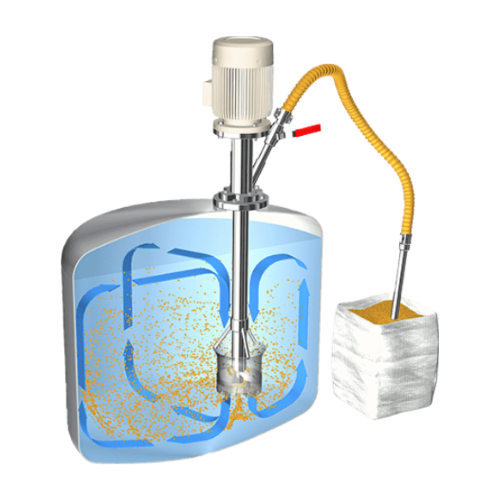

Powder dissolver for large liquid quantities

Achieve uniform powder blending swiftly with a vacuum-assisted system that pr...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

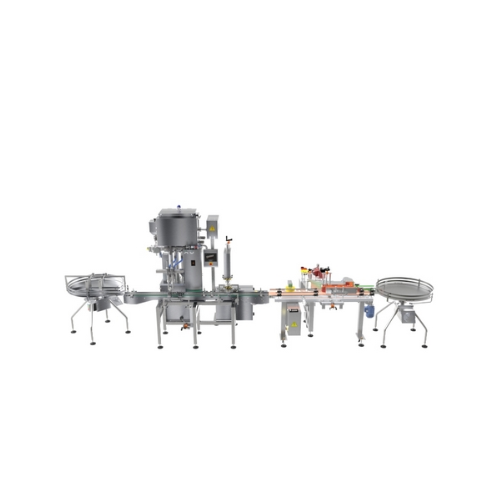

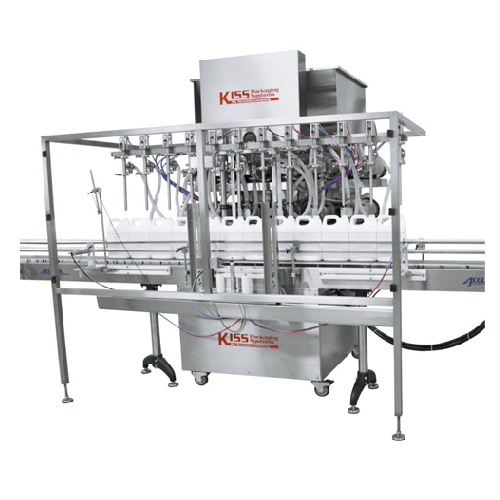

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

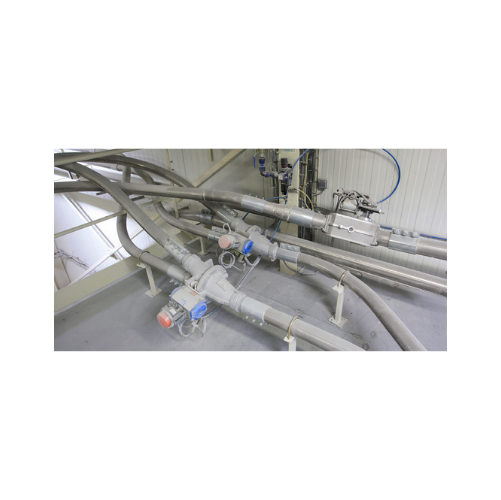

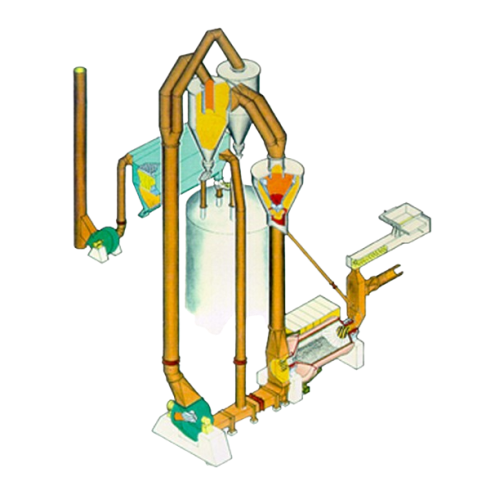

Pneumatic conveying systems for industrial applications

Efficiently transport bulk materials or liquids across your produ...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

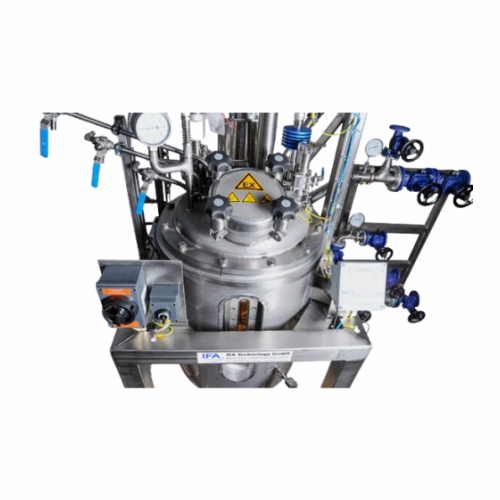

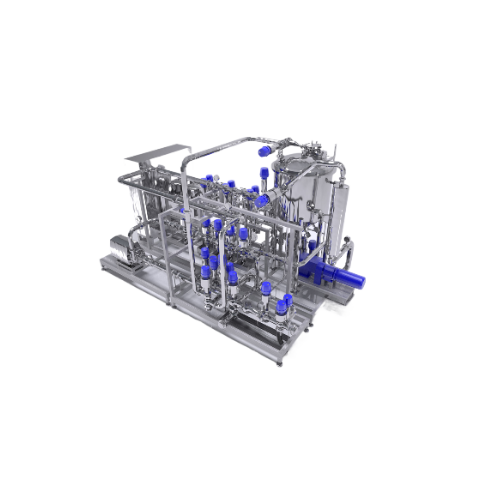

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Customised tank systems for liquid and bulk material storage

Ensure safe and compliant storage of liquids and bulk mater...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

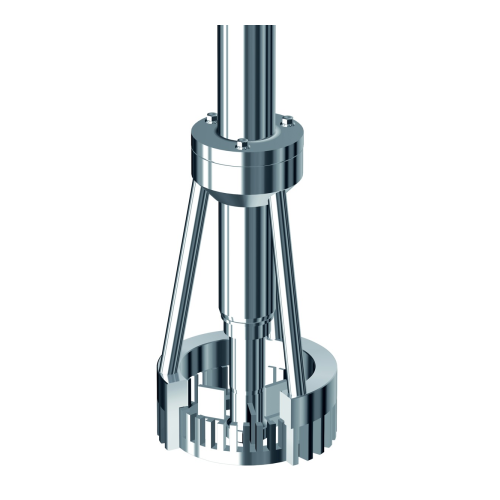

Immersion mill for pail and drum-sized batches

Streamline your production with a versatile solution that efficiently handl...

Immersion mill for particle reduction

Achieve streamlined particle size reduction and enhanced mixture homogeneity with imm...

Cylindro conical mixer for batch mixing

Maximize mixing efficiency in compact spaces with this versatile solution, ideal fo...

Horizontal pilot centrifuge for pharmaceutical applications

Achieve precise separation of solid and liquid phases with c...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Coaxial mixer for high viscosity liquids

Achieve seamless blending of high-viscosity materials with a coaxial mixer designe...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Heavy duty analytical sieve shaker for coarse-grained materials

Need precise particle size distribution for large minera...

Tapped density tester for pharmaceutical and chemical powders

Ensure precise density measurements for pharmaceuticals an...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Dipping centrifuge for precision coating processes

Achieve precise coating and oiling with customizable dipping and centr...

Industrial exhaust air treatment for food processing

Effectively eliminate volatile organic compounds and odors while max...

High temperature laboratory oven for precise heating

Achieve precise temperature control and uniformity essential for hea...

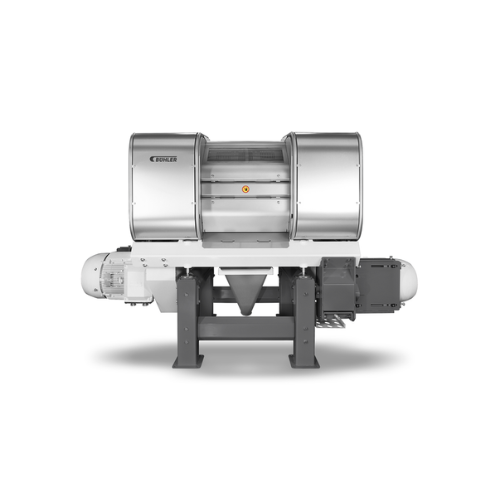

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

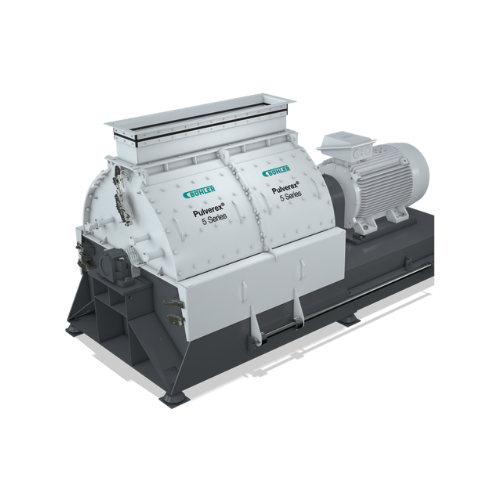

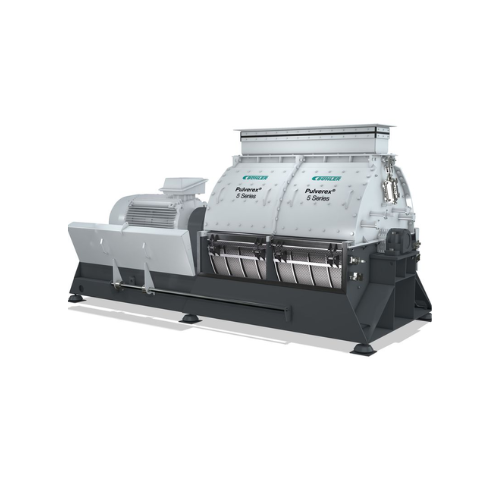

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Full-volume bead mill for wet grinding applications

Achieve superior dispersion and particle size consistency with advanc...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

Hammer mill for animal feed grinding

Achieve precise granulation with high throughput and energy efficiency, while reducing...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

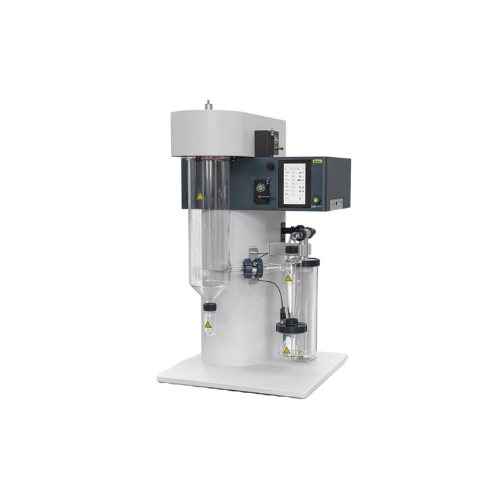

Laboratory spray dryer for organic solvent samples

Experience precise particle control and enhanced safety when convertin...

Inert loop for safe organic solvent spray drying

Ensure safe handling and efficient recovery of organic solvents in spray ...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

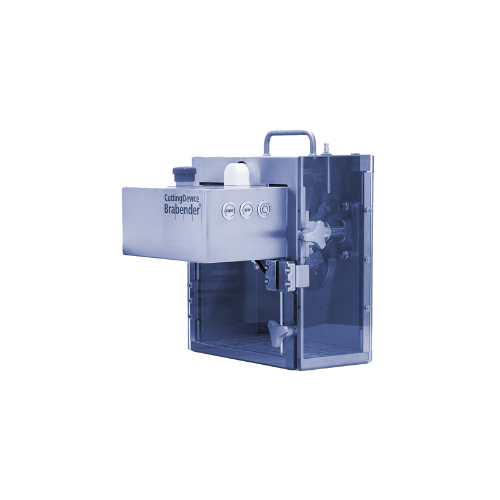

Laboratory cutting device for extrudates

For precise shaping of snack or feed extrudates, this compact cutting solution ens...

Crossflow filtration with sieve filter for difficult suspensions

Achieve precise separation and recovery in challenging ...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Pressure drum filter for ultra fine-grained products

When traditional filtration methods fall short, ensure ultra-fine pr...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with conti...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Ammonia chiller for industrial refrigeration

Achieve optimal energy efficiency and reduced operational costs in your cooli...

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditional...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

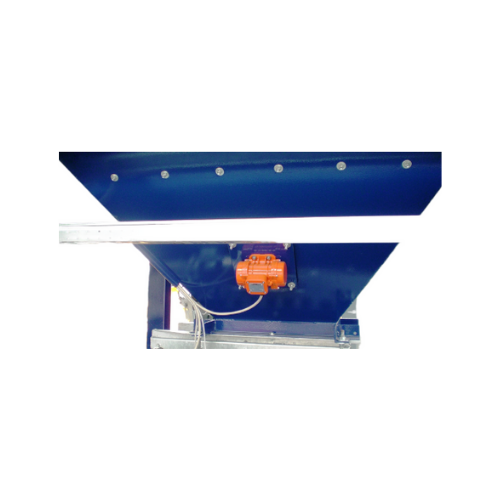

Precise discharge and dosing module for silos and containers

Ensure seamless material flow and accurate dosing with adva...

Bulk materials discharge solution for silos and containers

Ensure reliable material flow with a robust discharge solutio...

Powder wetting and dispersion system

Revolutionize your production with a system that seamlessly inducts, wets, and dispers...

Laboratory disperser for powder induction and wetting

Optimize your pilot and laboratory processes with a high-speed disp...

Inline disperser for homogeneous emulsions and suspensions

Achieve precise control over particle size and distribution w...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

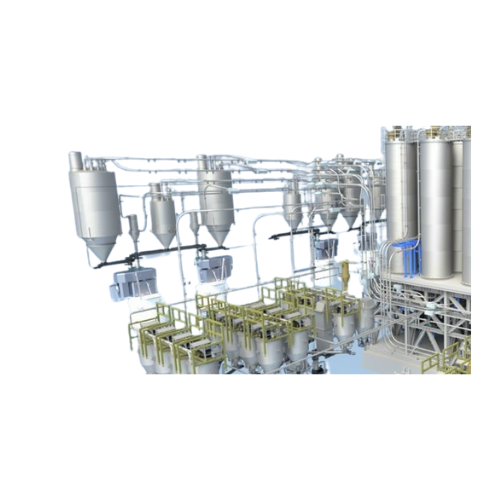

Dispersion paint production systems

Achieve 100% color accuracy and flexible production with our advanced system, ensuring ...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

High-shear batch disperser for chemical and food industries

Achieve unmatched dispersion and emulsification precision wi...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Dissolver for high-viscosity products through floor installation

Optimize production of ultra-high viscosity products wi...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Dispersing system for high-viscous products

Achieve precise mixing and dispersing of high-viscous products with advanced f...

Top-mounted disperser for high-viscosity products

Achieve rapid, uniform dispersion of ultra-high viscosity materials wit...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Basket mill for paint and varnish production

Achieve optimal particle size and product consistency with this advanced bask...

Laboratory basket mill for fine grinding in industrial applications

Optimize your laboratory’s efficiency with hi...

Milling beads for wet grinding in paint industry

Enhance product uniformity and grinding efficiency with specialized milli...

Continuous mill for nano range fine grinding

Achieve ultra-fine particle size in continuous processes, ensuring consistent...

High-efficiency disperser for viscous products

Achieve precise control over the mixing and dispersing of high-viscosity ma...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

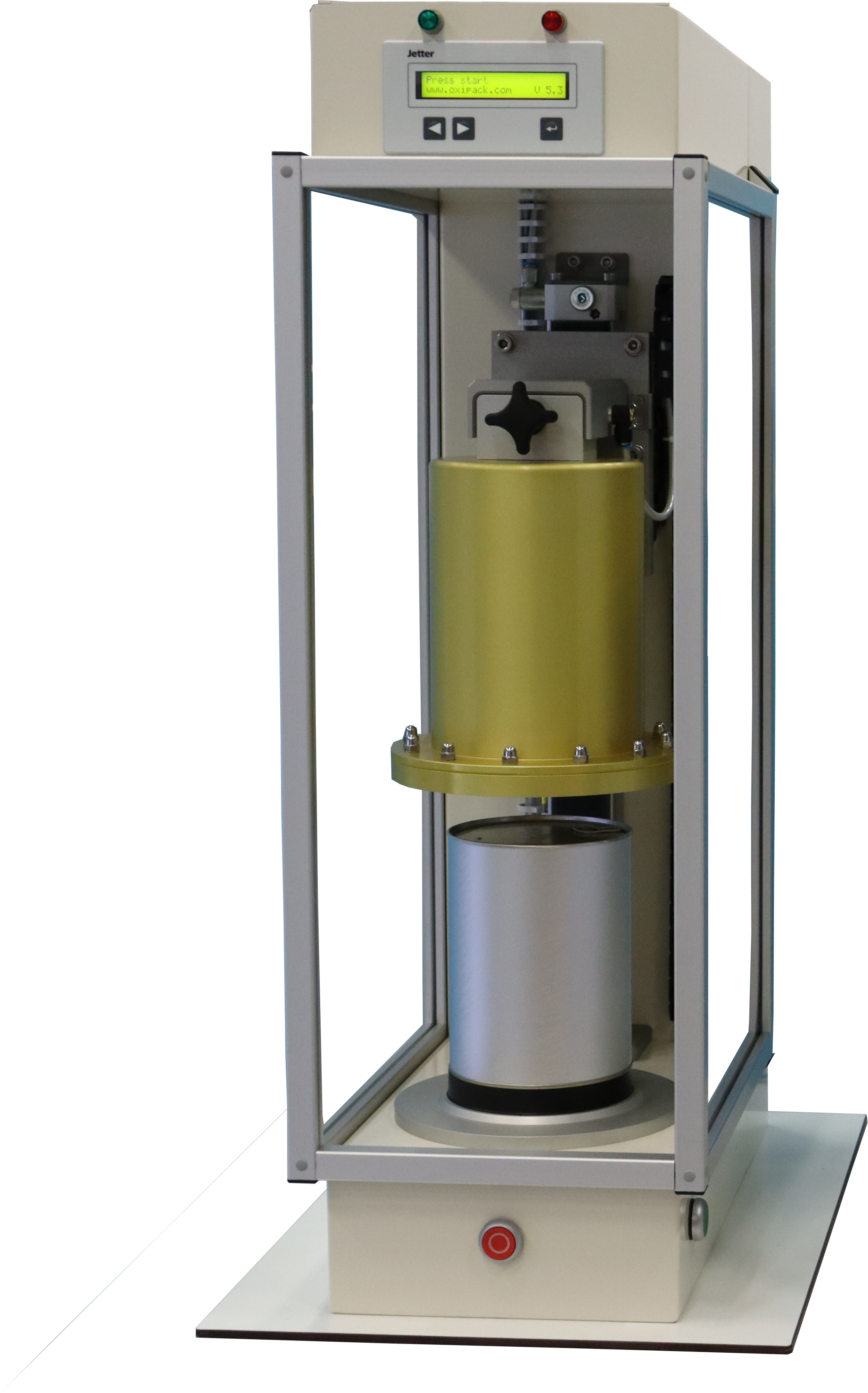

Leak testing system for aerosol cans

Ensure the integrity of your aerosol and metal packaging with a high-speed leak testin...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Continuous single shaft mixer for waste treatment

Achieve consistent mixing homogeneity and prevent dead spots in your pr...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Single shaft screw feeders for consistent material feeding

Tackle challenging materials with poor flow characteristics b...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

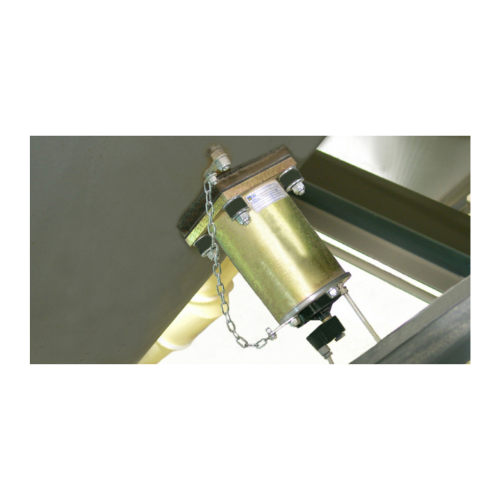

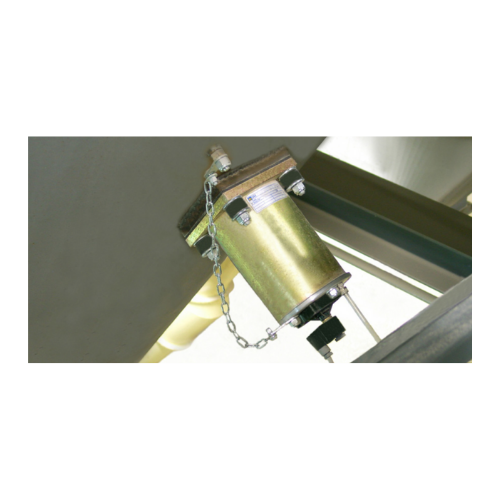

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Continuous impact vibrators for bulk solids discharging

Optimize your discharging process with vibrators that effectively...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Loading bellows for drums and Ibcs

Ensure dust-free loading of bulk solids into confined spaces with compact, pneumatically...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

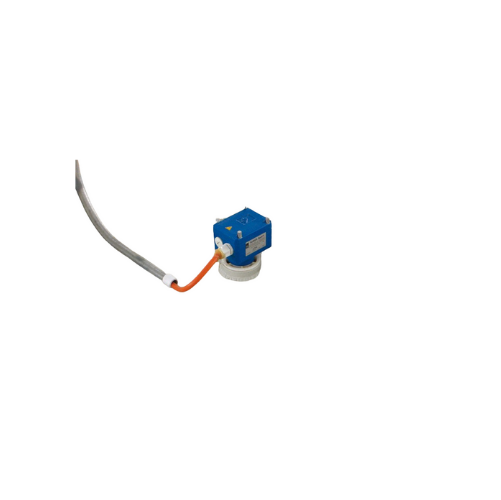

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Vertical conveyor for fine aggregates and minerals

Optimize the handling of abrasive materials with a vertical conveying ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

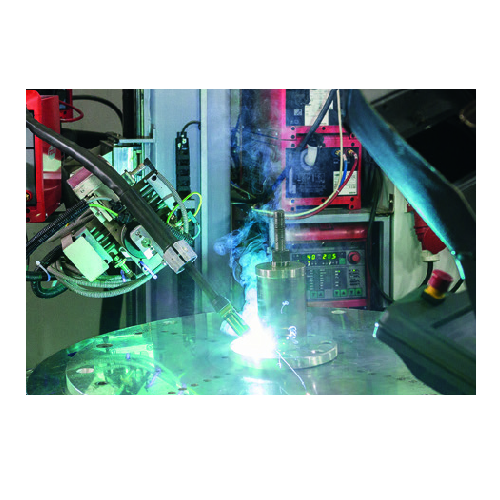

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Vacuum dispersion system for high-viscosity products

Eliminate air inclusions during production with a modular vacuum sys...

Vacuum basket mill for high-viscosity product processing

Achieve exceptional fine milling results while preventing air in...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Vacuum disperser for high-viscosity products

Optimize high-viscosity product dispersion and prevent air inclusions with a ...

Vacuum dissolving system for high-viscosity products

Achieve flawless dispersion of high-viscosity substances under vacuu...

Production dissolver for high-viscosity products

Achieve optimal dispersion and grinding of high-viscosity substances with...

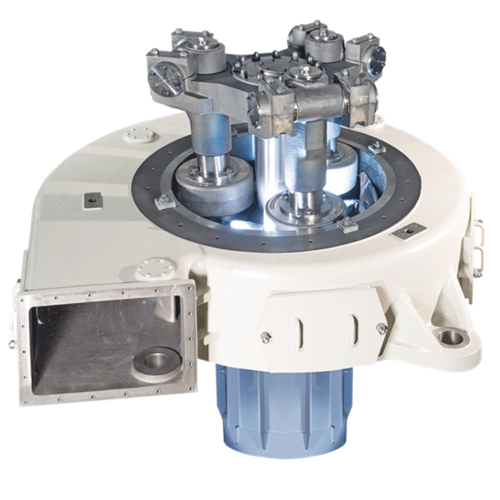

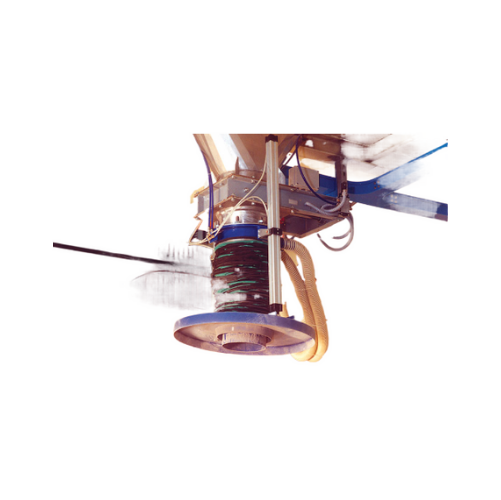

Rotary homogenizer for high shear mixing

Achieve precise homogenization of various viscosities with advanced rotor-stator t...

Rotor-stator homogenizer for high shear batch processing

Achieve ultra-fine particle distribution and stable emulsions wi...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

Explosion-proof horizontal bead mill for paint production

Ensure ultra-fine particle size and consistent quality with an...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

High-capacity dissolvers for industrial mixing

Enhance your production line with precision mixing, achieving consistent di...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

Explosion-proof production vacuum disperser for viscous products

Achieve precise and reliable dispersion of high-viscosi...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

High-efficiency immersion mill for medium viscosity products

Achieve precise particle size reduction and superior disper...

High-efficient industrial immersion mill

Achieve rapid, efficient dispersion and fine grinding in demanding production envi...

High-performance dissolver for industrial dispersion processes

Optimize your dispersion processes with this advanced dis...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Dissolving system for high-viscosity products

Optimize the dispersion of high-viscosity liquids and pastes with this versa...

Production dissolver with scraper for high-viscosity products

Efficiently tackle high-viscosity material processing with...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

Explosion-proof dissolver for high viscosity products

Optimize your high-viscosity material processing with an explosion-...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high-viscosity products

Optimize your production by eliminating air inclusions and ...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Explosion-proof basket mill for large scale production

Enhance your production line with an explosion-proof basket mill t...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Efficient high-volume dissolver with scraper

For high-viscosity formulations, this advanced dissolver with integrated scra...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Laboratory bead mill for sample dispersion

Ensure precise particle size reduction with versatility and ease, enabling effi...

Nano bead mill for laboratory wet grinding

Achieve ultra-fine particle dispersion and consistent milling results with this...

Homogenizer for high viscosity liquids and solid suspensions

Struggling with homogenizing high-viscosity ingredients and...

Agitator for horizontal storage tanks

Efficiently blend various viscosities in horizontal tanks, ensuring optimized flow pa...

Mobile stainless steel tank agitator for various industries

Optimize liquid blending processes with this mobile tank agi...

Homogenizer for low to medium viscosity media

Achieve uniform mixing and prevent air entrapment in low to medium viscosity...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Drum blender for closed barrels

Efficiently mix liquids and slurries inside closed drums with a specialized agitator designe...

Industrial mixer for facade paint and plaster

Optimize your facade paint and plaster production with this mixer designed f...

Semi-automatic stands blender for facade paints

Optimize your paint production with a versatile stirring system designed f...

Industrial mixer for product-critical processes

When dealing with high-hygiene requirements and complex mixing tasks acros...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Quickchange systems for vibratory separator screen changes

Streamline your production with a system that enables rapid s...

Vibratory finishing and deburring technology

Achieve precise surface finishing and deburring with advanced vibratory motio...

Portable and fixed mount mixing system

Optimize your mixing operations with a versatile system that adapts seamlessly betwe...

Continuous drying for cohesive and non-cohesive pastes

Transform high-viscosity liquids and pastes into fine, flowable po...

Dosing system for packaging lines

For producers looking to optimize their packaging lines, this dosing system offers precis...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

Versatile rotary filler-capper for liquid products

Optimize your liquid product production with a versatile solution that...

Anti-corrosion filling system for aggressive liquids

When dealing with corrosive liquids, ensure durability and safety wi...

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

Pet bottle production for small and medium outputs

Optimize your production line by manufacturing PET bottles in-house, r...

Space-saving packaging solution for high-velocity production

Optimize your manufacturing floor space with a versatile in...

Semi-automatic weight filling system for liquid products

Achieve precise and versatile liquid filling performance with th...

Blow-fill-cap solution for low/medium batch production

Streamline your production line with a compact blow-fill-cap syste...

High hygienic filler for chilled beverages

Enhance cold beverage production with a modular, hygienic filler offering chemi...

Yoghurt and dairy desserts filling solution

Maximize efficiency in filling and sealing multi-product dairy desserts and be...

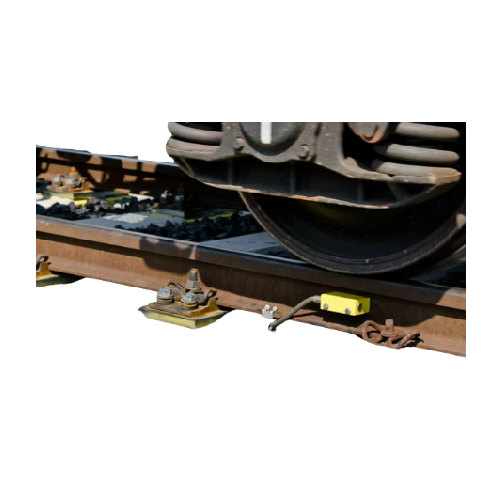

Pit scales for industrial weighing

Optimize material flow and ensure precise load determination with a robust pit scale sol...

Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide lega...

Scale hopper for bulk solid material handling

Ensure precise measurement and efficient transport of bulk solid materials w...

Crane weighing system for precision measurement

Ensure precise and temperature-resistant weighing during high-demand opera...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Bin weighing system kits for precise weight control

Ensure accurate material measurement in challenging environments with...

Industrial grinding solution for hard and abrasive materials

Efficiently grind and mill a spectrum of materials from coa...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Vertical ring-roll mill for pulverizing minerals

Achieve precise particle size control and efficient material processing w...

Ultrafine powder mill for coatings and pigments

Optimize your ultra-fine powder production with this precise grinding and ...

Solids flow meter for bulk solid streams

Ensure precise bulk material measurement with a system designed for accuracy and r...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Loss-in-weight feeder for small volume bulk solids

Achieve precision feeding for small volume bulk solids with this advan...

Apron weighfeeder for sticky bulk materials

Optimally handle challenging, sticky materials with precision and consistency ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

U-belt conveyor for bulk material transport

Optimize your high-speed bulk material transport with this space-saving convey...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Loss-in-weight feeder for poor flowing bulk solids

Efficiently handle poorly flowing bulk solids with unparalleled precis...

Multipurpose feed station for bulk solids

Optimize your production line with a versatile feeding station designed for simu...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

En-masse chain conveyor for bulk material handling

Streamline your bulk material handling with a gentle, efficient system...

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in de...

High volume 3D shaker mixer for ceramics

Achieving consistent homogeneity and the logistics of handling and introducing lar...

Self-cleaning bead mill for highly viscous materials

To prevent blockages, clogging, and cross-contamination coming from ...

Horizontal disc bead mill for liquid chemicals

Processing toxic chemicals requires high compliance with safety standards a...

Inline solid-liquid mixer for chemicals and paints

Incorporating solids into liquids is a critical process in producing p...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

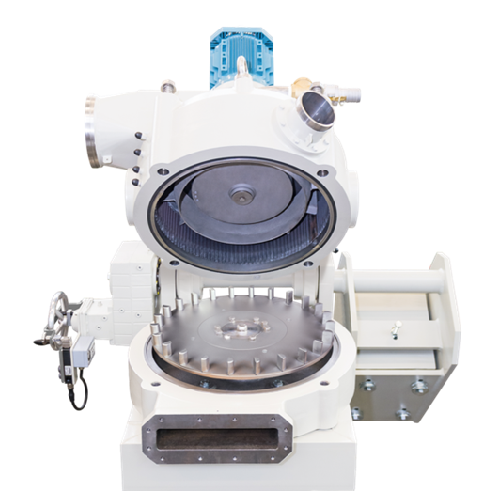

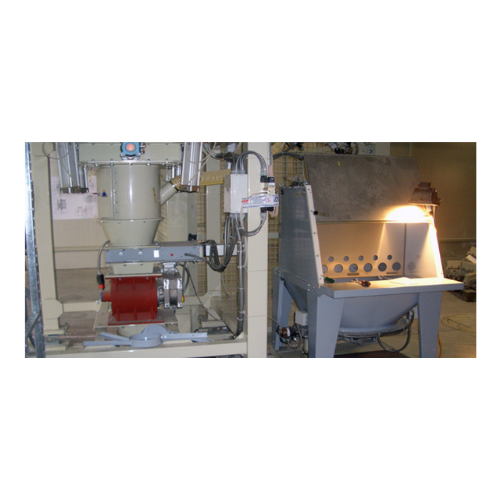

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Automatic can sealer

If you need to cap paint, glues, and solvents containers and are currently manually placing the lids, yo...

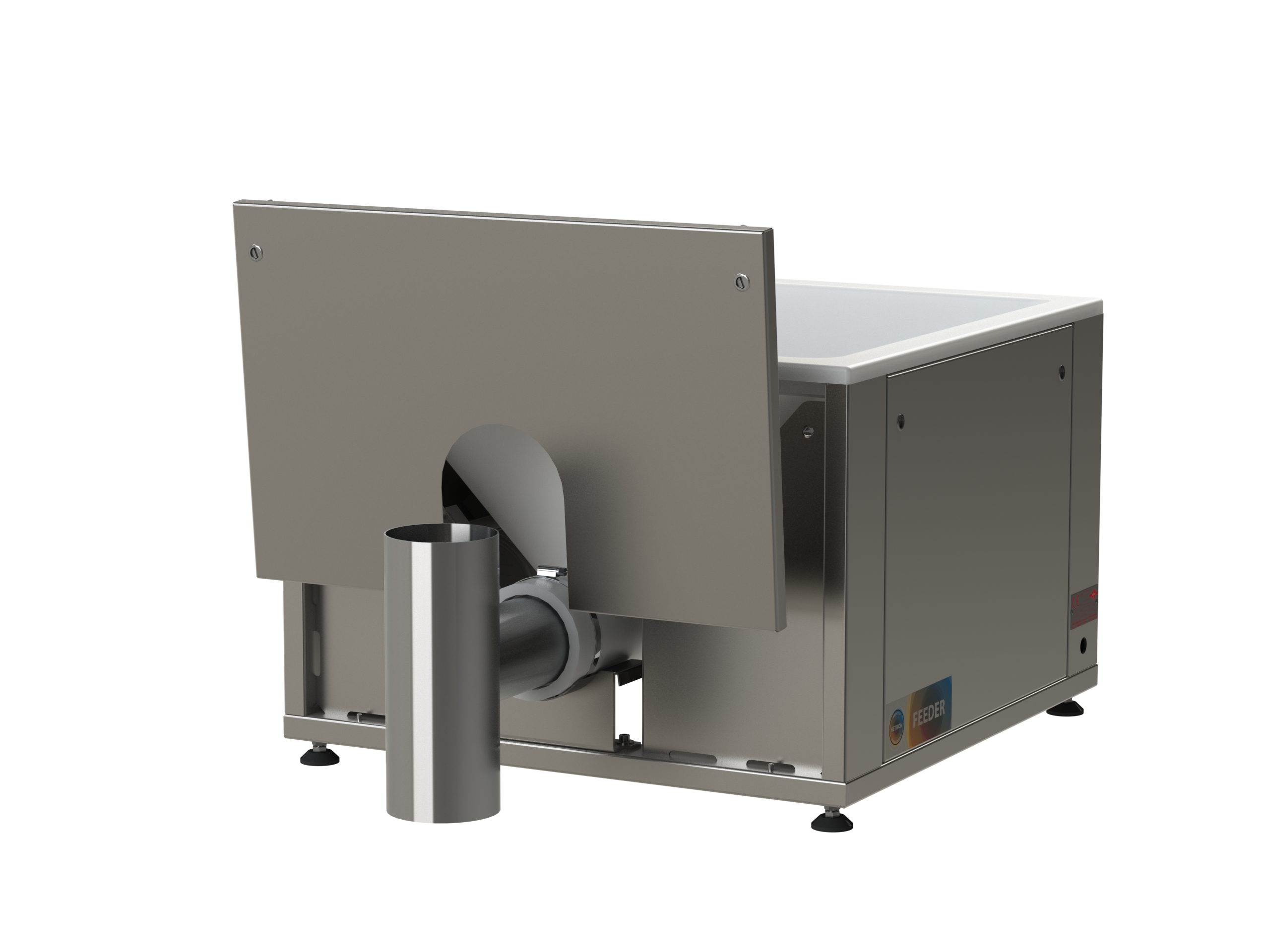

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Vertical scraper centrifuges

Vertical Bottom discharge Centrifuges work discontinuously, discharging the solids to the botto...