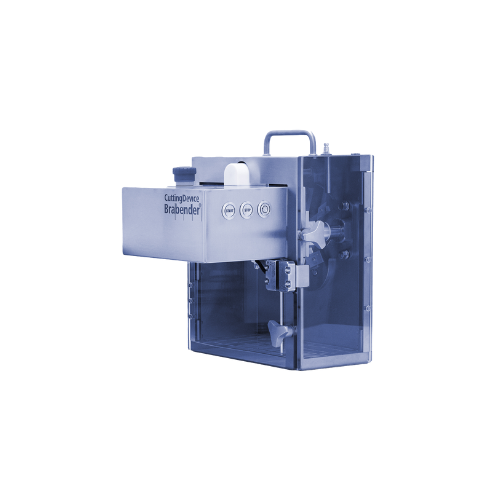

Laboratory cutting device for extrudates

For precise shaping of snack or feed extrudates, this compact cutting solution ensures optimal control and flexibility in laboratory settings, catering to diverse material trimming needs with exceptional hygiene and ease of use.

Trims and Cuts Extrudates Precisely

The Brabender Cutting Device is specifically designed for precise trimming of extrudates in laboratory and industrial settings. This device caters to snack, feed, and chemical production, including polymers and cosmetics, where exact lengths are crucial. Equipped with an adjustable blade holder, the device accommodates four or eight blades, achieving cutting frequencies of up to 9,000 cuts per minute. Its flexible design enables easy integration with Brabender single- and twin-screw extruders, supporting both manual and continuous operations. The cutting process is continuously observable through a Plexiglas pane, ensuring safe and efficient operation. The device also prioritizes hygiene and maintenance with straightforward access for cleaning, while its durable blades are easily replaceable, enhancing longevity and efficiency in high-speed production environments.

Benefits

- Enhances production efficiency with up to 9,000 cuts per minute.

- Facilitates adaptability with configurable blade setups for diverse applications.

- Simplifies maintenance with easy access for cleaning and quick blade replacement.

- Increases safety with blade positioning that avoids direct die contact.

- Optimizes workflow by integrating seamlessly with existing extruder systems.

- Applications

- Academic research, Polymers, Antifreezing agents, Cosmetics and body care products, Feed extrudates, Organic chemicals, Snack extrudates, Elastomers, Additives, Paints

- End products

- Engine coolant tablets, Hydraulic fluid additives, Potato chips, Biodegradable packing peanuts, Pet food kibble, Acrylic paints, Lip balm, Silicone rubber seals

- Steps before

- Extrusion, Preheating

- Steps after

- Cooling, Packaging

- Input ingredients

- snack extrudates, feed extrudates

- Output ingredients

- trimmed snack extrudates, trimmed feed extrudates

- Market info

- Brabender is renowned for producing high-quality, engineered-to-order lab equipment for material testing, particularly in food and plastics industries, specializing in precision instruments for measuring, preparation, and processing.

- Knife speed

- 4, 500 cuts/min (4 knives), 9, 000 cuts/min (8 knives)

- Knife holder capacity

- 4 to 8 knives

- Blade width

- 19 mm

- Adjustment mechanism

- Manual handle for blade-die gap

- Viewability

- Plexiglas pane observation

- Safety feature

- Zero position away from die

- Knife speed control

- Software-controlled

- Knife holder extension

- 4 to 8 knives

- Cutting frequency

- 4500 to 9000 cuts/min

- Blade observation

- Plexiglas pane view

- Ease of cleaning

- Easy access to parts

- Safety stop position

- Zero position away from die

- Compact footprint

- Optimal dimensions for laboratory operation

- Discharge method

- Container provided for extrudates

- Control panel type

- Software-controlled knife speed

- Knife holder extendability

- Extendable from 4 to 8 knives

- Blade width

- 19 mm

- Control panel type

- Software-controlled

- Integration possibilities

- Compatible with Brabender single- and twin-screw extruders

- Knife holder extension

- 4 to 8 blades

- Blade replacement

- Easy replacement of wider cutting blades (19 mm)