Let's make synthetic fertilizer

Find innovative synthetic fertilizer equipment and connect directly with world-leading technology suppliers

Synthetic fertilizers are made of nitrogen, phosphorus and potassium and are often produced as dry pellets or soluble product.

Select your synthetic fertilizer process

What are you making?

Tell us about your production challenge

For growth, a plant needs nitrogen compounds. Proteins are essential for all living organisms and are composed of nitrogen-containing the necessary 21 amino acids. As only a few microorganisms are capable to absorb elemental nitrogen from the air, high-yield agriculture needs fertilizer added to the soil. Apart from nitrogen, phosphorus and potassium are two essential macro elements for plant growth. Phosphorous compounds are needed for the energy transfer of living organisms and potassium is responsible for the osmotic flow in cells. In addition to these main components, a lot of microelements are needed for healthy plant vegetation, these micro compounds are also mixed into the fertilizer.

Synthetic fertilizer processing

Fertilizer plants produce so-called NPK (nitrogen, phosphorus, and potassium) fertilizers, a mixture of the three major elements for good quality and quantity of crops. The most important nitrogen fertilizer is ammonium nitrate. Elemental nitrogen of air and hydrogen of natural gas form ammonia. One part is oxidized to nitrous oxides, absorbed by water to form nitric acid. The reaction of this acid with ammonia forms the base of nitrogen fertilizer. As ammonium nitrate is explosive, to counter this, limestone or dolomite powder is mixed with the melted compound. Another synthetic fertilizer, phosphorus fertilizer, has raw materials that consist mostly of minerals, like several apatites. The insoluble compound is treated with sulphuric acid to form the fertilizer superphosphate. Potassium compounds (mainly chloride, sulfate, and carbonate) are other minerals.

When making fertilizer, the different compounds are granulated and blended together with the help of a rotating drum. The fertilizer now takes its shape in the form of small beads. Any oddly sized beads are then taken out, after which the rest has inert dust applied which helps the fertilizer to keep its moisture. The beads are then dried and transported to a bagging machine.

Blending fertilizer with dolomite for safety

Due to the explosive attributes of ammonium nitrate, limestone or dolomite is blended with the pure compound of nitrogen fertilizer. An additional important side effect of adding this alkaline material is to neutralize the acidification of the soil caused by the fertilizer. The rocks are ground to a fine powder before mixing with fertilizer. High capacity milling can be achieved by a ball mill. By using a classifier, the size of the powder particles can be adjusted to suit the further fertilization-making process.

Transforming powder into dust-free briquettes

A granular product is preferred in the fertilizer market because it can avoid dust generation and lasts longer. Dust can be dangerous for operators and create a harmful working environment. To get dust-free materials, a blend of powder is fed into a compactor where two rollers compress and form briquettes. This briquette technique uses compression forces to remove and entrap air and mechanically bind the fine particles into larger, easy-to-handle material.

Bagging and packing fertilizer

Each end-user asks for a certain type of packaging when it comes to the granulated fertilizer and the bulk material is packed in a bag size that is suited for different demands. Smaller gardeners prefer a bag of one to two kilos, where a bigger customer might require 25-kilo bags. Then there is of course the industrial agricultural partner that requires fertilizer in big bags. For transportation, the bags are placed on a pellet in neat stacks by a robot, wrapped in stretch foil to protect it against possible breakage and spoilage.

Some Background To Synthetic Fertilizers

Synthetic fertilizers are artificially manufactured chemical compounds used to provide essential nutrients to plants. Unlike organic fertilizers, synthetic fertilizers do not contain any organic matter or microbes. Which are crucial for improving soil fertility and soil structure. Although synthetic fertilizers can increase nutrient uptake in plants. They also have several negative impacts on the environment. These negatives include contributing to water pollution and soil degradation. On the other hand, organic fertilizers, such as bone meal, contain natural sources of essential plant nutrients. Thus are able to improve soil fertility and structure by providing organic matter and beneficial microbes to the soil. Therefore, using organic fertilizers is a more sustainable and environmentally friendly way to improve soil health and promote plant growth.

Synthetic fertilizer making videos

Fertilizer bagging and packing

Which synthetic fertilizer technology do you need?

Liquid fertilizer filling and capping monobloc

Production lines for bottling liquid products such as liquid fertilizer, re...

On-line particle size and shape analyzer for industrial processes

Optimize your production line with precise, real-time...

Vacuum belt filters for solid-liquid separation

Ensure high-efficiency solid-liquid separation and maximize filtrate recov...

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains d...

Vacuum table filters for liquid-solid separation

Optimize your liquid-solid separation with vacuum table filters, designed...

Integrally geared centrifugal compressors for process gases

Optimize your production efficiency with our integrally gear...

Vacuum filtration for large suspension volumes

For high-volume slurry filtration, streamline your process with a rotary di...

Manure decanter for nutrient separation

Transform livestock manure into valuable resources by efficiently separating and ex...

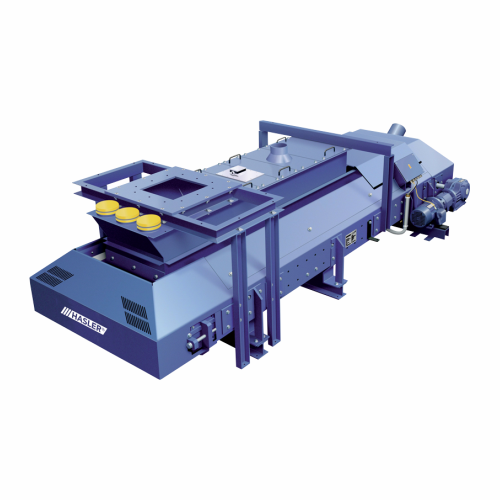

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Bead mill for crop protection

To optimize qualities like particle size, distribution, solubility, and miscibility of active ...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Industrial solution crystallization plants

Optimize your production with tailored crystallization systems designed for eff...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Scale hopper for industrial batch weighing

Optimize your production line with precise batch weighing and mixing, ensuring ...

Loss-in-weight feeder for poor flowing bulk solids

Efficiently handle poorly flowing bulk solids with unparalleled precis...

Exergy pressurized superheated steam dryer

Traditional dryers and heat transfer systems, like belt-, drum- or bed dryers a...

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

High yield filter press

When a saturated slurry or sludge must be dehydrated with high yield results mining and other heavy i...

Overhead filter press

To name just a few of the myriad applications for overhead filter presses: industrial mineral industrie...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Vertical form, fill and seal machine for bags from 5 to 50 kg

To securely create, dose and pack larger quantities of mat...

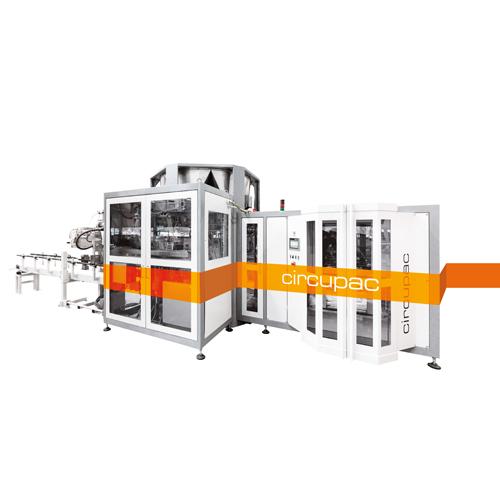

Automatic bagging machine for open mouth bags

Open mouth bags allow for a variety of different products to be packaged, wi...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Vertical peeler centrifuge

A vertical peeler centrifuge is used to separate solids, usually to separate fine particles from ...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....