Making Phosphorus Fertilizer

Find innovative production technology for making phosphorus fertilizer and connect directly with world-leading specialists

Phosphorous is literally at the root of the food industry. An essential ingredient in agriculture, it contributes to plant seed formation and root development. But farmers do not simply give their soil a dose of the chemical element. Instead, phosphorous fertilizer processing equipment blends it with other materials to manufacture effective formulas.

Select your phosphorus fertilizer process

Tell us about your production challenge

Reduce chlorine content with freshwater

Phosphate occurs naturally in the phosphate rock, but it is not available to plants in its raw form. Instead, the extracted mineral is ground finely and chemically treated to produce phosphate fertilizer.

Beneficiation is the production process to remove impurities from the ore. Besides undesired metals or clay, the rock may contain substantial chlorine traces that lead to corrosion further down the production line. Wash the raw material with freshwater to minimize its chlorine content before processing.

Manufacture high-quality phosphate fertilizer by calcinating ore

The dry fertilizer production technique subjects the pre-processed phosphate material to high heat. Treat the ore with silica in a furnace, then distill the remaining elemental phosphorus and dissolve it in water to obtain white acid.

This type of phosphoric acid produces a high-purity compound suitable for food-grade applications, including toothpaste and detergents.

Phosphorus fertilizer processing equipment to make green acid

Despite its content purity, producing white acid is energy-intensive. An alternative method is to react the phosphate feed with a chemical to generate green acid.

Treat the ore with sulfuric acid in a reaction tank to trigger the formation of phosphoric acid. The wet process develops gypsum as a by-product that a filtration system discards. Purify the remaining material with steam, but remove moisture content with an evaporator before sending it to the formulation blender machine.

Blend phosphoric acid with ammonium to enhance its nutrient properties

Phosphoric acid produced by either the dry or wet methods is reheated to raise the substance concentration. This superphosphoric acid has a phosphate content between 72% and 76%.

But soils are not treated with pure phosphate fertilizers. Superphosphoric acid is blended with ammonium to increase availability and improve the physical attributes of the final product. To manufacture solid granular fertilizers, mix the dry ingredients in a granulator.

Processing steps involved in phosphorus fertilizer making

Which phosphorus fertilizer technology do you need?

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while ...

Loss-in-weight feeder for poor flowing bulk solids

Efficiently handle poorly flowing bulk solids with unparalleled precis...

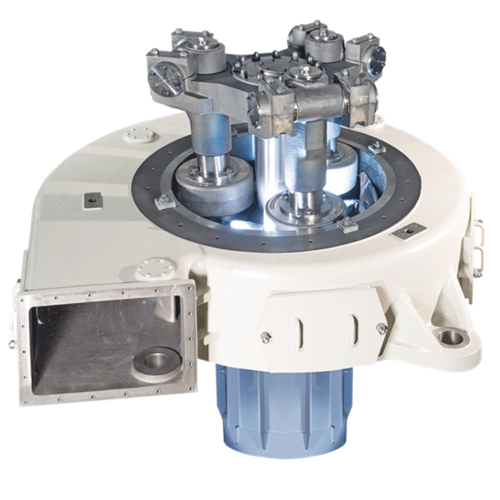

Bead mill for crop protection

To optimize qualities like particle size, distribution, solubility, and miscibility of active ...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Vertical form fill seal machine

There is an increasing demand for a range of different package sizes of the same product. If...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

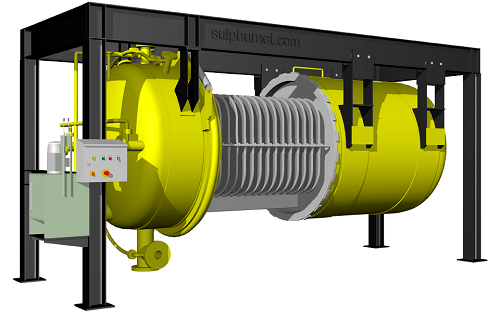

Self-cleaning filter for sulphur

If you are a small-scale business, the cleaning of moving parts in a traditional filtration...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

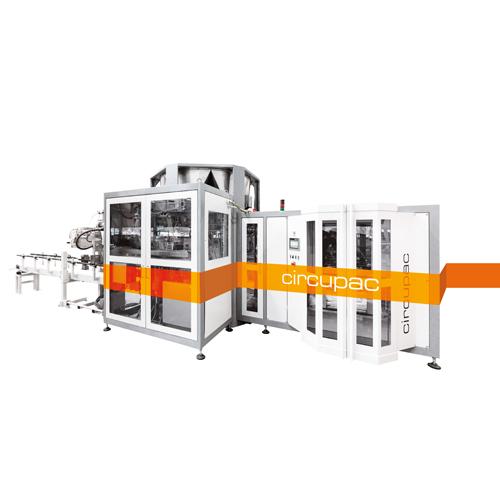

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Bagger for open mouth bags

Where a stand-alone bagger is required for filling large, open mouth bags, a delivery method is n...

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....