Meat And Bone Meal

Find innovative production technology for making meat and bone meal and connect directly with world-leading specialists

Meat and bone meal production is used in pet food and animal feed, but the risks of mad cow disease make it unsuitable for ruminant feed. Bone meal and meat meal are by-products from slaughterhouses and livestock farms. They can come as separate meals or mixed into meat and bone meal (MBM) which offers more nutrients and increases amino acids in animal feed formulations. But besides feed, MBM can also be used as fertilizer and fuel.

Tell us about your production challenge

Meat and bone meal production from by-products of the animal meat industry

Meat and bone meal is a processed by-product of the animal meat industry. MBM is produced mainly from cattle, poultry, and swine slaughterhouse leftovers such as bone, meat, organs, tissues, and fat. It contains protein, minerals such as phosphorus and calcium, and amino acids, contributing to a rich diet for poultry, swine, and sometimes for fish. In fact, it can replace up to 50% of fishmeal in some fish diets.

Meat and bone meal production gives an economical and viable source of nutrients for the animal feed and pet food industry. However, the protein, vitamins, and minerals content varies depending on the quality of the raw material and the proportion of meat, bones, and other organs.

Apply heat treatment for the rendering process

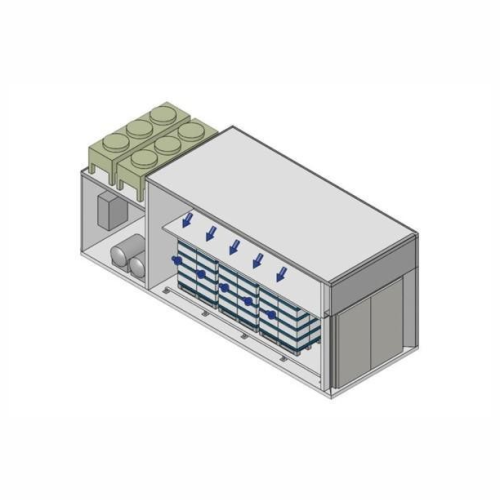

Heat treatment is necessary to avoid spoilage by killing hazardous microorganisms in the raw material that will be transformed into meat and bone meal. The heat treatment in the rendering process can be wet or dry. In the wet process, fat is separated from the other organs when boiling in water. In the dry process, the raw materials go to a steam-jacketed container or cooker, which separates fat with indirect heat. The dry process can be in batch or continuous.

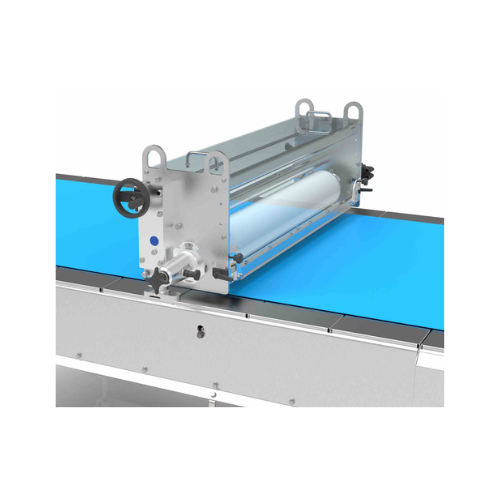

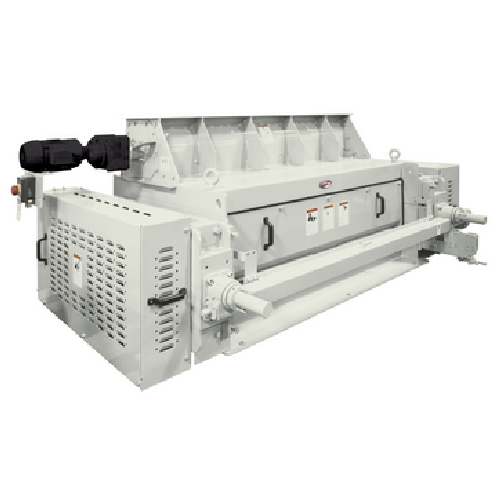

The rendering process to obtain meat and bone meal consists of crushing the flesh, bone, tissues, and organs. Cook the crushed material to separate the fats. Press the mixture to complete the separation of the fats and obtain a protein cake, which is ground into the meal. You can add value to your meat and bone meal if you dry and mill it further. The filtered animal fat can also be used as an animal feed ingredient.

The rendering process is a circular economy solution for the waste generated by the meat industry

Like other meals from the rendering process, making meat and bone meal is a circular economy solution for the waste generated by the meat industry. Slaughterhouses produce millions of tons of animal by-products unsuitable for human consumption, creating an enormous amount of waste that may end in landfills and cause an environmental disaster.

The rendering upcycles meat, bones, blood, feathers, and offal waste, into MBM, blood meal, feather meal, and animal fat, that can be used for animal feed and pet food, as well as for fertilizers. Meanwhile, new studies show that the material can also be used as biofuel.

Processing steps involved in meat and bone meal making

Which meat and bone meal technology do you need?

Portioning system for small and medium-sized meat slices

Achieve precise meat portioning with volumetric forming, optimiz...

Industrial meat mincer with mixing system capacity

Optimize your meat processing workflow with a versatile mincer that se...

Refrigerated meat mincer for hygienic meat processing

Ensure optimal hygiene and extend shelf life with advanced refriger...

Band saw for cutting various heights

Achieve precise cuts and optimize safety in your production line with a versatile band...

Industrial band saw for processing meat and bones

Enhance your meat processing efficiency with precise bone and meat cuts...

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining...

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Industrial brine mixers for meat and poultry processing

Optimize your production line with brine mixers that ensure homog...

High-capacity ring-die pellet mill for animal feed production

Optimize your high-capacity feed production with this pell...

Laboratory pellet press for testing and formulation

Achieve precise pellet formulation and performance testing with versa...

Roller mills for high-demand crushing applications

Optimize your production line with versatile roller mills designed to ...

Efficient barley malt crushing with roller mills

Achieve precise particle size control in your processing line with a robu...

High-capacity pellet crumbler

Achieve precise pellet size reduction with this high-capacity solution, designed for effortles...

Pellet crumbler for animal feed pelleting

Optimize pellet size reduction with precise control and high efficiency, ensurin...

Small-scale pellet mill for animal feed production

Achieve precise pellet formulation for diverse feedstocks with an effi...

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

Industrial feed conditioner for optimal moisture absorption

Achieve precise control of moisture and temperature to enhan...

Industrial weighing and batching system for meat, poultry and seafood

Optimize your production line with a high-precisi...

Decanter centrifuge for protein extraction

Efficiently enhance your recovery of valuable proteins and fats with customizab...

Spiral oven for high-capacity cooking

Optimize your cooking with a compact spiral oven that enhances capacity and hygiene w...

High velocity vertical impingement oven for meat and poultry

Achieve superior cooking uniformity and rapid throughput wi...

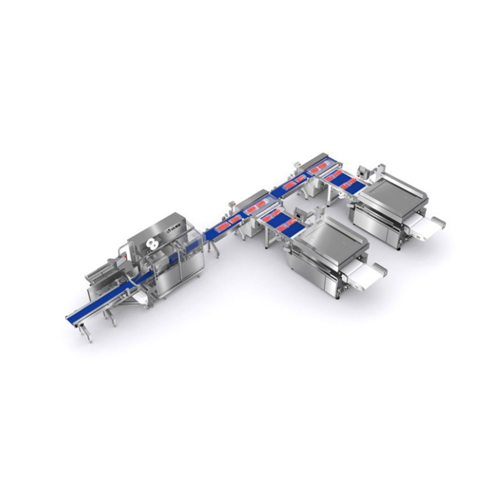

Automated meat portioning and trimming solution

Enhance your production line efficiency with a robotic system that automat...

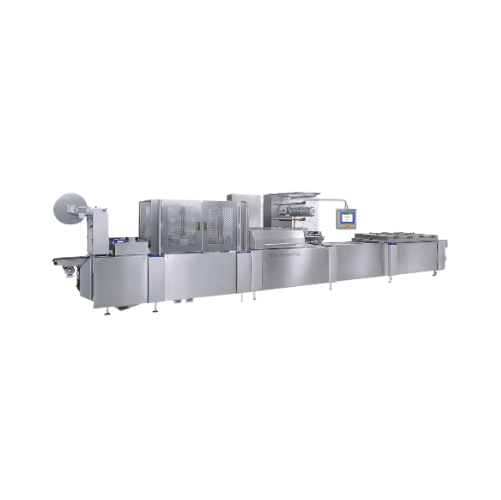

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system d...

3-phase separating decanter for animal by-products

Enhance your recovery processes with a decanter centrifuge designed to...

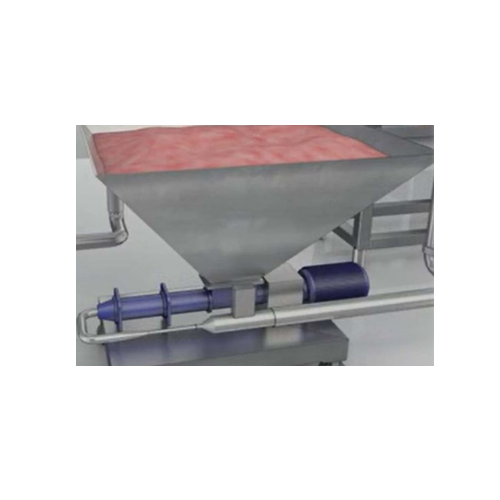

Meat injection system for pet food production

Integrate fresh meat seamlessly into your pet food production line, enhancin...

Energy saving cooling tumbler for meat, poultry, and fish processing

Optimize your meat, poultry, and fish processing w...

Vacuum packaging for industrial cuts of meat

Enhance production efficiency and packaging integrity with a system designed ...

Rendering unit for poultry feces processing

Transform poultry by-products into valuable feed additives efficiently, enhanc...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...