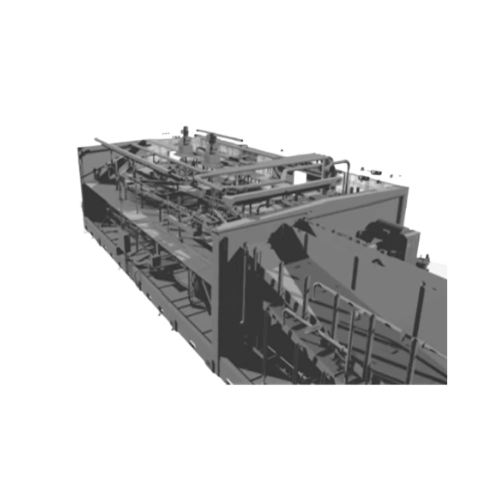

Spiral oven for high-capacity cooking

Optimize your cooking with a compact spiral oven that enhances capacity and hygiene while offering precise control over airflow and humidity for a variety of foods.

Cooks and Self-Stacks High-Capacity Food Products

The Stein GCO II GYRoCOMPACT® Self-Stacking Spiral Oven from Stein harnesses forced convection and self-stacking technology to offer compact, high-capacity cooking solutions for poultry, meat, seafood, and ready meals. This oven employs the innovative FRIGoBELT® conveyor, ensuring hygienic and efficient cooking through dynamic air control and automatic humidity management. Capable of processing a wide range of products, such as grilled chicken and seafood medley trays, it meets large-scale production demands with operations up to 20 tiers. Integrated with a fully automatic Clean in Place (CIP) system, it simplifies maintenance and sanitation. The robust design, featuring a stainless steel thermal fluid heat exchanger, ensures reliable performance, while customizable options accommodate specific production needs.

Benefits

- Maximizes production efficiency with high-capacity self-stacking design, minimizing required floor space.

- Enhances product consistency through precise humidity and thermal control, ensuring optimal cooking quality.

- Reduces sanitation labor with a fully automatic Clean in Place (CIP) system for quick and thorough cleaning.

- Decreases energy consumption with dynamic air control and variable-speed fans, optimizing airflow direction.

- Supports diverse food production with customizable configurations tailored to specific processing requirements.

- Applications

- Seafood, Meat, Ready meals, Poultry

- End products

- Cooked beef patties, Lasagna, Chicken alfredo pasta, Stuffed peppers, Beef stew, Grilled chicken breast, Bbq pork belly, Breaded chicken tenders, Grilled salmon fillets, Seafood medley trays, Shepherd's pie, Roasted turkey slices, Chicken pot pie, Steamed shrimp, Glazed pork ribs

- Steps before

- Portioning, Slicing, Coating, Injection, Marination

- Steps after

- Chilling, Freezing, Packaging, Weighing, X-ray Inspection

- Input ingredients

- coated products, uncoated products, raw poultry, meat, seafood, ready meal components

- Output ingredients

- cooked coated products, cooked uncoated products, cooked poultry, cooked meat, cooked seafood, fully cooked meals

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Conveyor System

- Self-stacking FRIGoBELT®

- Air Flow

- Vertical, reversible up or down

- Heat Transfer Modes

- Multiple

- Heat Exchanger

- Stainless steel thermal fluid

- Clean in Place (CIP)

- Fully automatic

- Humidity Control

- Humitrol III automatic

- Belt Type

- Variable mesh pitch

- Drives

- Electric

- Controls

- ProLINK with Allen Bradley PLC

- Working mechanism

- Self-stacking spiral oven

- Integrated steps

- Cooking

- CIP principles

- Fully automatic Clean in Place (CIP)

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC Controlled with Allen Bradley HMI

- Airflow control

- Dynamic Air Control (DAC) for reversible airflow

- Cleanability

- Fully automatic Clean in Place (CIP)

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Biological compatibility

- Food-grade materials

- Machine footprint

- High capacity in a small footprint

- Enclosure material

- Fully welded stainless steel

- Mesh type

- Variable mesh pitch stainless steel FRIGoBELT®

- Conveyor system

- Self-stacking FRIGoBELT® conveyor system

- Infeed section length

- 4 ft.

- Control panel type

- ProLINK Controls with Allen Bradley PLC based HMI graphic interface