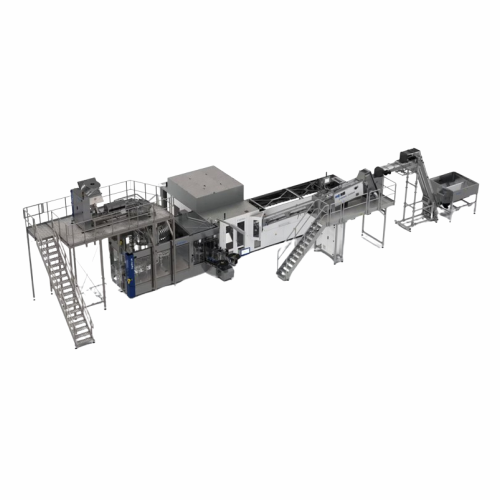

Wet-section block solution for non-carbonated water

Streamline your bottling operations with a compact solution that efficiently performs blow molding, labeling, filling, and capping for non-carbonated water, drastically reducing space requirements and operational costs while enhancing production continuity and sustainability with advanced recycling and energy-saving technologies.

Integrated Bottling of Non-Carbonated Water

The ErgoBloc LM from Krones is an advanced wet-section block designed for the seamless integration of stretch blow moulding, labelling, filling, and capping processes within non-carbonated water bottling lines. Uniquely engineered to optimize space and efficiency, it operates at speeds up to 55,000 containers per hour, accommodating PET and rPET in volumes ranging from 0.2 to 2.0 litres. This system minimizes energy consumption through features like highly-efficient infrared heating and the Air Wizard Triple compressed air recycling. Its modular design includes a single HMI for operational simplicity and requires only one operator, significantly reducing overhead. Ideal for food and beverage industries focused on sustainability, the ErgoBloc LM offers customization options, ensuring alignment with specific production requirements while promoting hygienic design and efficient material handling.

Benefits

- Maximizes production efficiency by integrating blow moulding, labelling, filling, and capping into a single process.

- Reduces operational costs with compact design and centralized control, requiring only one operator.

- Enhances sustainability with significant energy savings and eco-friendly compressed air recycling.

- Supports lightweight and recycled PET containers, aligning with sustainability goals.

- Ensures optimal product quality with precise dosing and minimal contamination risk through state-of-the-art hygienic design.

- Applications

- Non-carbonated water, Beverage containers, Pet containers, Lightweight containers, Recycled pet (rpet) containers

- End products

- Lightweight bottled drinking water, Bottled table water, Recycled pet bottled spring water, Ozonised non-carbonated bottled water, Pet bottled mineral water

- Steps before

- Preform manufacturing, Preform heating, Container cleaning

- Steps after

- Bottle capping, Quality inspection, Packing and palletizing

- Input ingredients

- Cylindrical PET containers, Standard PET containers, Lightweight PET containers, Ozonised non-carbonated water, Plastic reel-fed labels, rPET containers

- Output ingredients

- Labelled bottles, Capped bottles, Filled bottles, Non-carbonated water bottles, Up to 55, 000 containers per hour, 0.2 to 2.0 litre container volumes

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Output

- Up to 55, 000 containers per hour

- Processing Range

- Non-carbonated water (ozonised)

- Container Type

- PET

- Container Volume

- 0.2 to 2.0 litres

- RPET Compatibility

- Up to 100 percent

- Label Type

- Plastic reel-fed labels

- Automation

- Central HMI, PLC-controlled

- Energy Efficiency

- Infrared heating technology

- Compressed Air Recycling

- Air Wizard Triple

- Filling Valve

- Fully-electronic PFR with variable control

- Synchronized Motors

- Five high-precision Monotec servo motors

- Label Application

- No bottle – no label

- Drive Control

- Lubrication-free drive

- Compressed Air Usage

- No compressed-air consumption during filling

- Environmental Compatibility

- Enviro-compliant lubricants

- Automation level

- Single operator with central control

- CIP/SIP

- Automatic self-optimisation

- Batch vs. continuous operation

- Continuous

- Changeover time

- Minimal with skip-and-run technology

- Energy efficiency

- High with Air Wizard Triple system

- Cleaning method

- Automatic internal cleaning system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Up to 30% less space requirement compared to conventional block variants

- Container compatibility

- PET, cylindrical containers, up to 100% rPET

- Container volume

- 0.2 to 2.0 liters

- Control panel type

- Central HMI for complete operation

- Number of components

- Stretch blow moulder, Labeller, Filler

- Platform type

- Torsion-resistant platform

- Operator requirement

- One single operator

- Component transfer points

- Only four internal horizontal transfer points

- Heating technology

- Highly-efficient infrared heating

- Gripper type

- Actively controlled transfer grippers

- Servo motor type

- Five high-precision Monotec servo motors

- Reflector type

- Ceramic reflectors, Parabolic for top infrared emitter

- Compressed air system

- Air Wizard Triple with intermediate pressure levels

- No bottle functions

- "No bottle – no label" function

- Compact footprint

- Up to 30 percent less space requirement

- Control panel type

- Central HMI for complete operation

- Drive system

- Maintenance-free system with servo motors

- Integration possibilities

- Single integrated unit design

- Energy efficiency customization

- Air Wizard Triple compressed air recycling system

- Label application method

- Selective labelling

- Blow moulding station capacity

- Up to 2, 750 containers per hour

- Filling valve type

- Fully-electronic PFR filling valve

- Labelling process

- "No bottle – no label" function

- Maintenance requirement

- Maintenance-free ceramic reflectors

- Sustainability features

- Use of enviro-compliant lubricants

- Bottle handling improvement

- Highly-efficient infrared heating technology