Automatic tuna can filler

Streamline your high-speed canning operations with precision-engineered fillers that maintain optimal portion accuracy and consistency, maximizing your throughput and minimizing waste in tuna processing.

Automatically Fills and Portions Pre-Cooked Tuna

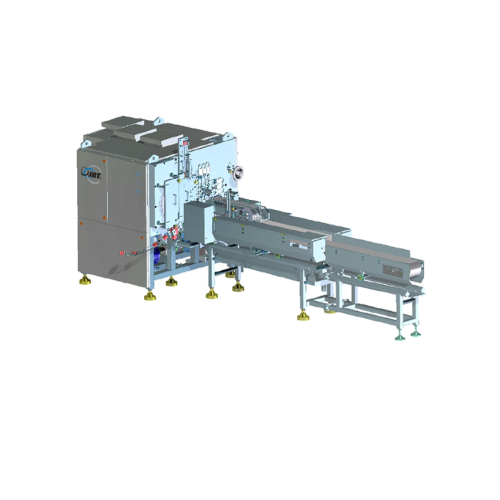

The Triple Can Tuna Filler Model 3866 from JBT FoodTech is an advanced rotary filler system engineered for high-speed, automatic filling of pre-cooked tuna into various can sizes. It integrates seamlessly into your food or seafood processing line, optimizing throughput with precision portioning. Its continuous operation ensures efficiency in tuna and seafood canning, making tuna salad kits, canned seafood mixes, and pre-cooked fish portions more accessible. The system is designed to handle solid products with high accuracy, utilizing a robust rotary mechanism that maintains constant fill rates and precise weight control. Constructed with durable materials suitable for food and seafood industries, it offers excellent corrosion resistance to ensure longevity and reliability. Featuring a PLC-controlled interface, the 3866 model supports remote monitoring and easy integration with existing systems. Further, it complies with industry standards for hygiene and safety, providing peace of mind in meeting regulatory requirements.

Benefits

- Enhances production efficiency by allowing high-speed, continuous filling.

- Ensures precise portioning, minimizing product waste and ensuring consistent can weights.

- Reduces labor involvement with automated, PLC-controlled operation.

- Seamlessly integrates with existing systems, facilitating smooth production line operation.

- Made with corrosion-resistant materials, ensuring durability and long-term reliability.

- Applications

- Tuna, Canned food, Pre-cooked fish, Seafood

- End products

- Pre-cooked fish portions, Pre-cooked tuna fillets, Canned tuna, Tuna salad kits, Canned seafood mix

- Steps before

- Pre-cooking, Brine Preparation

- Steps after

- Can Seaming, Sterilization

- Input ingredients

- pre-cooked tuna, open-top cans

- Output ingredients

- filled tuna cans

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Filling speed

- High production speeds

- Can size compatibility

- Various sizes

- Automation

- Automatic filling

- Filling precision

- High accuracy

- Drain weight control

- High drain weight

- Automation level

- Manual / PLC / SCADA

- Changeover time

- Minimized due to design

- CIP/SIP

- CIP available

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Optimized for high-speed filling

- Air incorporation control

- Automatic adjustment

- Machine footprint

- Compact design

- Discharge method

- Automatic

- Tuna can sizes

- Various sizes including large format

- Control panel type

- Automated control interface

- Machine model

- Triple Can Tuna Filler Model 3866, Model 3466, Model 3266

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / ERP

- Machine configuration

- Single / Triple can

- Filling head type

- Volumetric / Multi-head

- Customizable can size

- 100–1000 ml