Making Prefilled Syringes

Find innovative production technology for making pre-filled syringes and connect directly with world-leading specialists

A pre-filled syringe or PFS is a single-dose disposable syringe that is supplied loaded with the substance to be injected. By using a pre-filled syringe filling machine, you can have excellent dosage accuracy due to the exact filling of medications. During administration, safety from potential contaminants is also ensured as they are directly injected after opening. To further minimize the risk of contamination, pre-filled syringes are often filled and sealed in a sterile environment using stainless steel equipment.

Select your pre-filled syringes process

Tell us about your production challenge

Rising demand for sophisticated forms of drug delivery

Pre-filled syringes are gaining popularity over traditional syringes and vials and are considered one of the fastest-growing markets in drug delivery and pharmaceutical packaging industries. Pre-filled syringes address most of the issues from the traditional vial and syringe drug delivery such as less risk of contamination during administration as there is no need to draw out substances from a separate container and elimination of on-site vial cleaning and depyrogenation. Additionally, the exact fill volume of pre-filled syringes ensures that the correct dosage is administered to the patient, thereby minimizing potential dosage errors.

For healthcare providers, prefilled syringes provide the exact dosage for injection, preventing potential dosage error and offering quick and convenient drug administration. For pharmaceutical companies, pre-filled syringes eliminate drug overfill with its correct dosage. This means less waste of drugs and better efficiency in manufacturing since vials are usually overfilled to ensure that the transfer of drugs from vial to syringe is adequate.

Less contamination, safer application, from a material called Cyclo Olefin Polymer

Most prefilled syringes still use glass materials, but in some parts of the world like Japan, plastic-based materials are becoming more common due to their improved break resistance and less surface reaction from chemicals. New materials for syringes have been developed to improve safety from contamination using a material called Cyclo Olefin Polymer (COP) that looks and feels like glass but tougher. The piston in pre-filled syringes made of COP material is resistant to delamination, and its properties are retained at cryogenic temperatures, and it requires no lubricants or processing aids.

It is tungsten-free, which means it has fewer chances of health hazard due to tungsten exposure – tungsten can cause nausea and irritation to the lungs, eyes, and skin. COP is resistant to delamination; its properties are retained at cryogenic temperatures and require no lubricants or processing aids. This material can also be sterilized with gamma, ethylene oxide, and steam.

Administration of vaccines: tried-and-tested or new-and-improved?

Typical delivery methods for vaccines use multi-dose vials especially in mass vaccination programs. However, with the pre-filled syringes gaining market share, there is a shift towards using pre-filled syringes rather than multi-dose vials for vaccines. Based on global data of evaluation of vaccine presentation, pre-filled syringes can save time in mass immunization clinics. A study conducted by Scheifele and colleagues in Canada shows that, for every 1000 vaccine doses, vials took 36 hours while pre-filled syringes only took 27 hours.

This means that man-hours charged for labor costs are significantly lowered by 25 to 33 percent. Other advantages of using pre-filled syringes include the reduction of vaccine waste as it removes the variation inherent in drawing from a vial. There is also an increase in the consistency of administrating medicines across all locations as some healthcare workers are more adept than others in drawing medicines from a vial.

Pre-filled syringe filling machine for bubble-free liquid contents

Pharmaceutical companies that manufacture complex biologics require less headspace by using the bubble-free filling method. This is done by a stoppering technique called vacuum placement. A vacuum is pulled in each syringe that causes a differential pressure. The pressure draws the plunger into the syringe, leaving minimal headspace between the product and the plunger.

Advantages of a bubble-free pre-filled syringe filling machine are dosing accuracy with the removal of air bubbles, assurance of sterility because of fewer chances of plunger movement during shipping, and biologic stability due to less oxygen content that can affect oxygen-sensitive drugs. In addition to the filling machine, a labeling machine can also be used to apply labels to pre-filled syringes. This ensures that the syringes are properly labeled, which is important for tracking and tracing purposes.

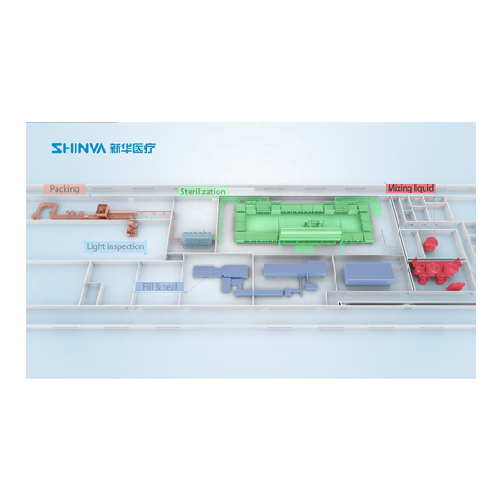

Processing steps involved in pre-filled Syringes making

Which pre-filled syringes technology do you need?

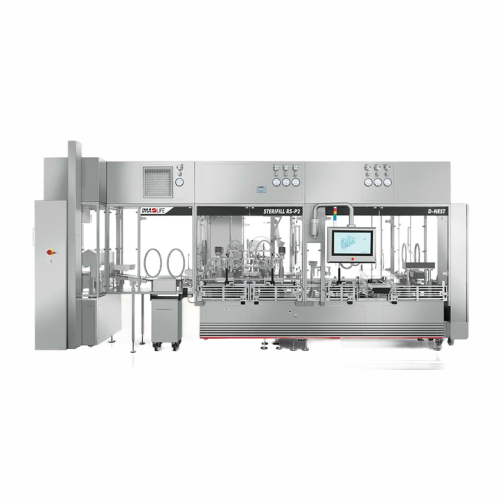

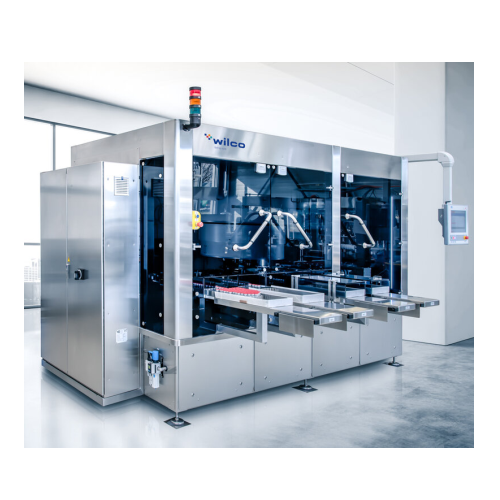

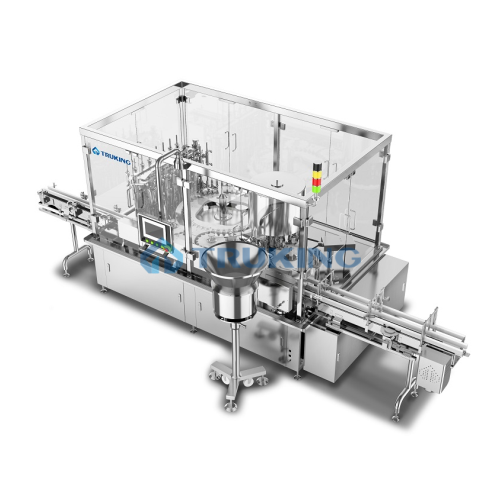

Aseptic filling system for biopharmaceutical products

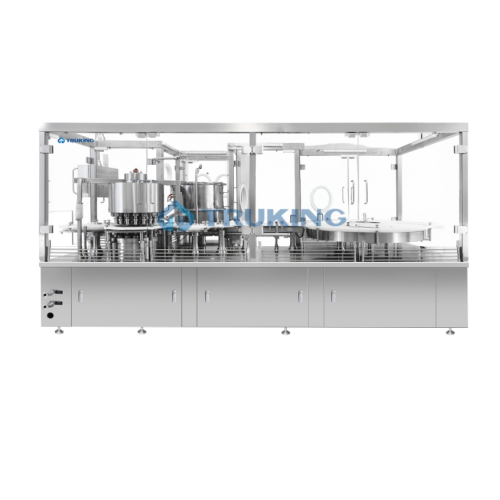

This system ensures sterility in high-volume aseptic filling operat...

Automatic syringe de-nesting solution

Streamline syringe handling with a high-speed solution designed to optimize de-nestin...

Automatic system for arranging inspected syringes in rondo-trays

Streamline syringe handling and packaging with this hig...

Oxygen headspace analyzer for container closure integrity testing

Ensure the integrity of oxygen-sensitive products wit...

Moisture and pressure headspace analysis for sealed parenteral containers

Ensure accurate moisture and pressure assess...

High-speed decontamination tunnel for pharmaceutical Rtu material

Ensure 100% sterility of ready-to-use materials with ...

Syringe assembly for pre-filled glass syringes

In the precise world of pre-filled syringe production, ensuring seamless as...

Linear vial washer for injectable drug containers

Achieve sterile conditions by efficiently removing contaminants from va...

Denesting system for Rtu syringes and vials

Need efficient denesting of sensitive pharmaceutical containers? Streamline yo...

Robotic sterile package opening system

Achieve sterile precision with a fully robotic system that streamlines primary packa...

Semi-automatic sterile primary packaging opener

Ensure sterile integrity in pharmaceutical packaging with this solution, w...

Depyrogenating tunnel for glass containers

Ensure the sterility of injectable medications by achieving reliable endotoxin ...

Thermoforming solution for clinical trials

Designed for precision and flexibility, this compact thermoforming machine stre...

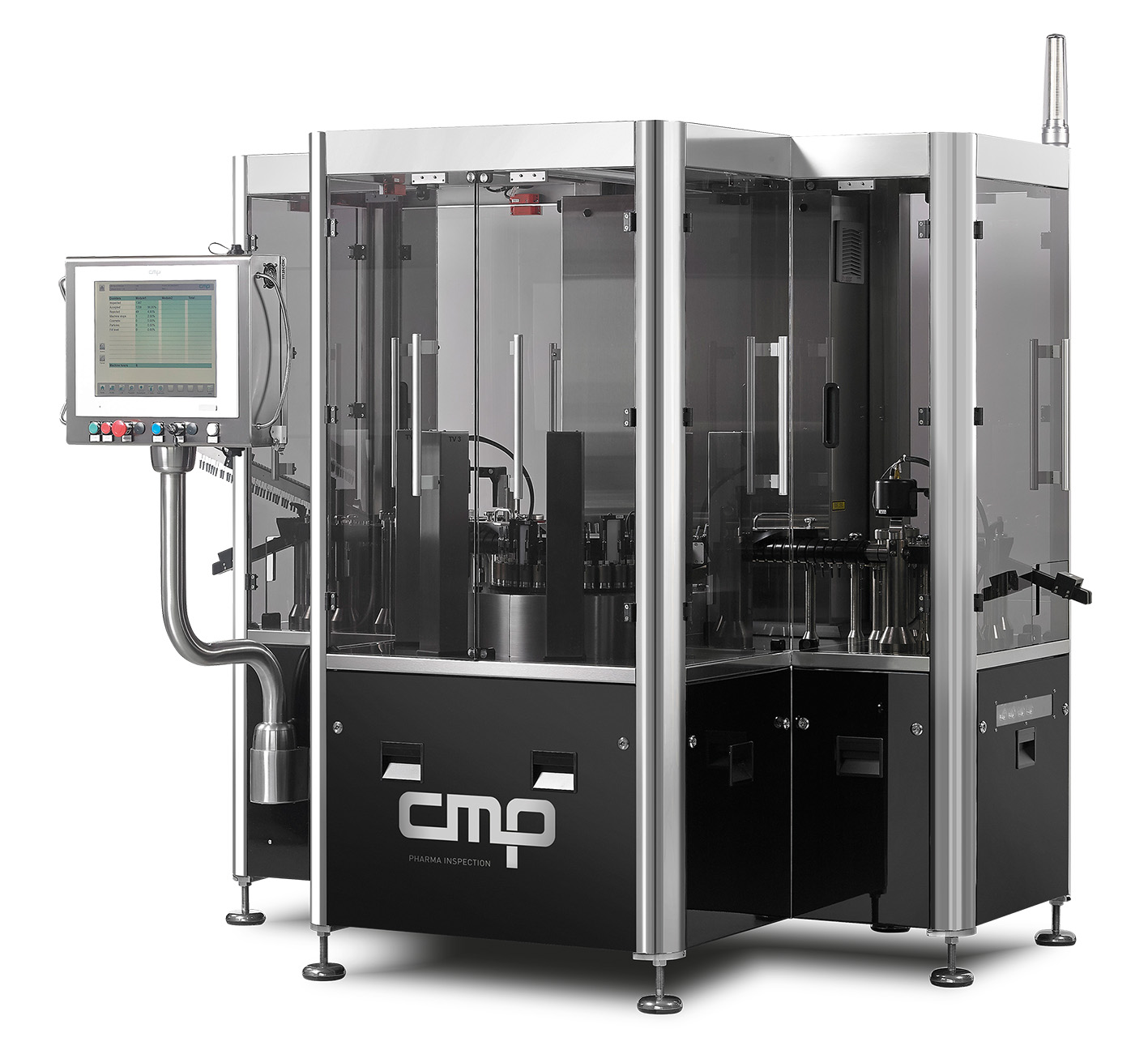

Syringe and cannula inspection system

Ensure flawless quality in injectable products with advanced inspection technology th...

Double bagging solution for sealed tubs

Achieve sterile packaging for medical and pharmaceutical products with a compact, e...

End-of-line casepacker for shipping boxes

Streamline your packaging line efficiency with this versatile casepacker, design...

Uv Dod Cmyk label and packaging film printer

Achieve high-precision, on-demand printing for narrow-web packaging films and...

Syringe assembly system for plunger rod, label, and safety device

Ensure precise handling and assembly of pharmaceutica...

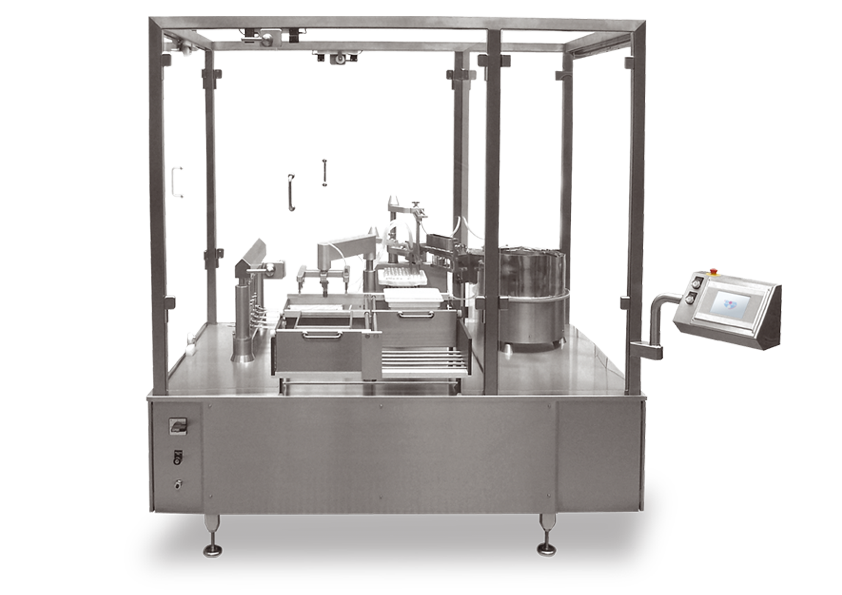

Aseptic syringe filling solution for Rtu containers

Streamline your pharmaceutical liquid filling operations with precise...

Benchtop filling solutions for small batch liquid medicine

Streamline your small batch liquid medicine production with p...

Sterile and nonsterile filling for injectable solutions

Efficiently fill and stopper injectable solutions in both sterile...

Sterility testing isolator for pharmaceutical labs

Ensure reliable sterility testing in a controlled sterile environment ...

Sterilizer loading solutions for biopharma and research laboratories

Streamline your sterilization process with ergonom...

Pharmaceutical sterilization with steam/air mixture

Achieve sterile, dry, and ready-to-use pharmaceutical products with p...

Steam sterilizer for pharmaceutical production

Ensure consistent, contamination-free sterilization of pharmaceutical compo...

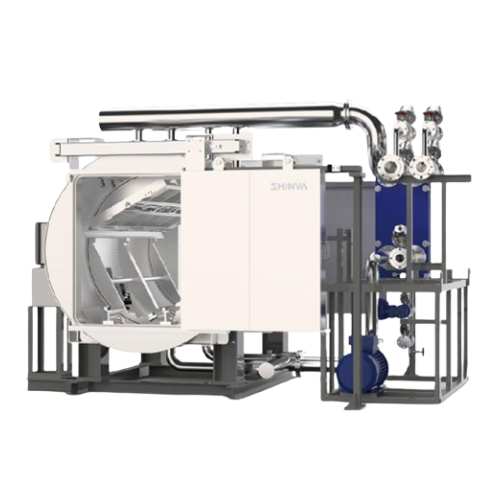

Superheated water sterilizer for large volume parenterals

When sterilizing large volumes of liquid products, achieving p...

Iso 5 Hepa cart for aseptic material transfer

Ensure aseptic conditions during storage and transfer with this compact HEPA...

Steam air sterilizer for aqueous solutions

Overcome the pressure challenge in sterilizing aqueous solutions, effectively p...

Modular cleanroom panel systems

Transform your cleanroom projects with modular panel systems that streamline installation an...

Custom automation for drug-device filling and assembly

Efficiently integrate precise filling and assembly for biopharmace...

Modular sterility testing isolator for pharmaceuticals

Achieve uncompromised sterility with modular isolators designed fo...

High-throughput aseptic isolator for syringes and vials filling

Streamline your aseptic filling process with a high-spee...

High quality sterile filling system

Experience unparalleled precision in aseptic filling with this advanced system, designe...

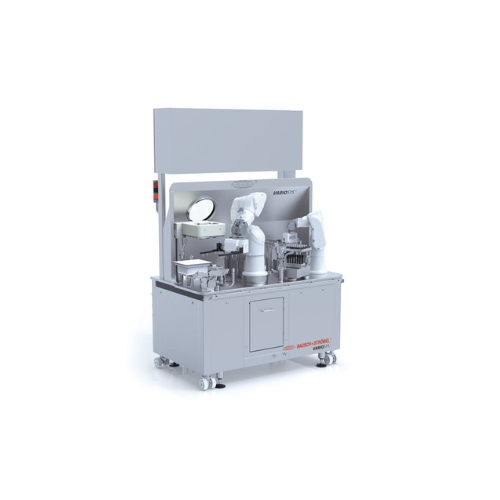

Sterile robotic filling for ready-to-use vials and syringes

Achieve precise and contamination-free filling for biopharma...

Compact aseptic vial filling system

Optimize your aseptic liquid filling with a compact system designed for seamless integr...

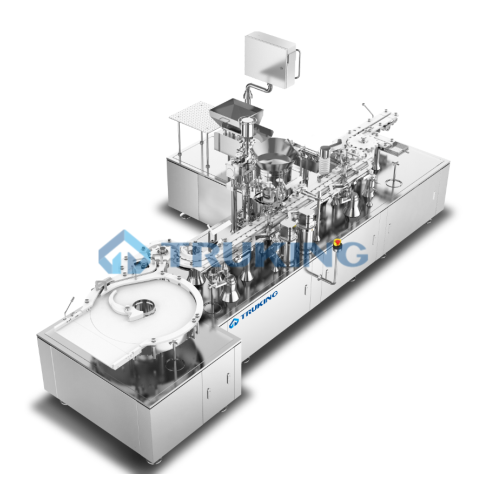

High-speed syringe assembler and labeller

Streamline your syringe production with a high-speed solution that assembles and...

Automated container loading system for ampoules and syringes

Ensure precise loading and nesting of sterile containers in...

Cartridge and disposable syringe closing solution

Ensure precise closing of pre-filled syringes and cartridges with custo...

Silicone spraying unit for laboratory and small-scale production

Ensure precise silicone application for cartridges, syr...

Automatic tub opening and denesting module

Optimize sterile vial processing by efficiently opening and denesting tubs for ...

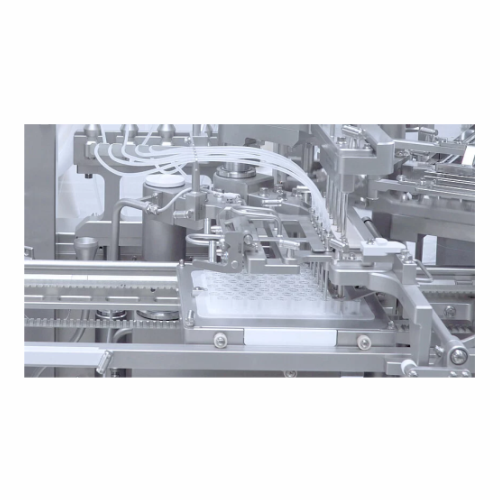

Filling and closing system for nested containers

Optimize liquid formulation packaging with a high-speed system designed f...

Automatic tub de-bagging and de-nesting solution

Efficiently prepare your RTU containers by seamlessly integrating de-bagg...

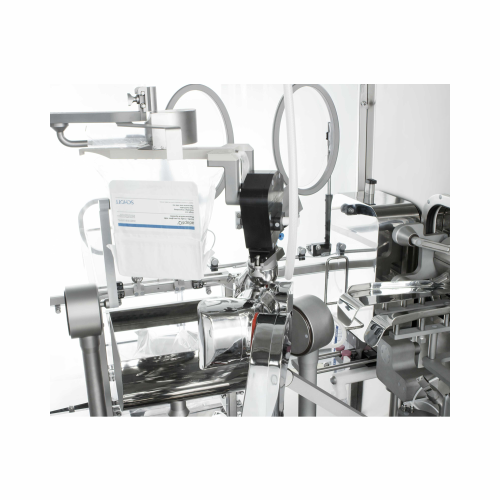

Labeling and assembly for disposable syringes

Ensure precise labeling and assembly of disposable syringes with a compact, ...

Tray loader for pharmaceutical containers

Maximize efficiency in aseptic fill-finish lines with precise and rapid tray loa...

Wet cleaning system for pharmaceutical cartridges

For optimal sterile product outcomes, this system ensures precise and e...

Vial and cartridge filling and closing system

Optimize your aseptic fill-finish process with high-speed, continuous operat...

Automatic labeling system for pharmaceutical containers

Streamline your pharmaceutical packaging with precision labeling,...

Fully automatic linear labeling system for bottles

Optimize your bottle labeling process with precision and speed, ensuri...

Automated washing system for vials, syringes, cartridges, and ampoules

Achieve sterile conditions with this high-speed ...

High-speed washing system for ampoules and vials

Ensure contamination-free ampoules and syringes with this advanced washin...

Hot air sterilization for glass containers

Ensure precise and uniform sterilization of glass ampoules, vials, and syringes...

Sterile transfer chamber for pharmaceutical components

Ensure the sterility of your components rapidly with an enclosed c...

High-speed syringe plunger rod assembly

Achieve seamless syringe preparation with high-speed plunger rod assembly, ensuring...

Closure system for aseptic containment

Achieve secure and verifiable seals for sterile pharmaceuticals with advanced closur...

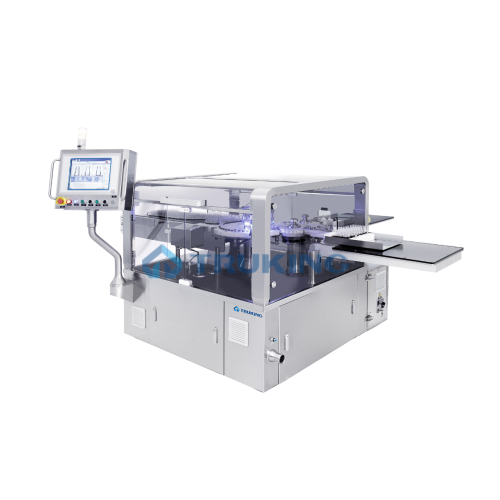

Automatic visual inspection for sterile preparations

Ensure the integrity of sterile products with precise visual inspect...

Customized Hvac system for pharmaceutical clean rooms

Achieve seamless sterilization and contamination control in clean r...

Vhp biodecontamination passbox for laboratory equipment

Ensure effective decontamination for heat-sensitive and non-autoc...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

Syringe needle inspection module for pre-filled syringes

Ensure precise needle geometry with high-speed X-ray inspection,...

X-ray inspection module for pre-filled syringe needles

Ensure sterility and product integrity in high-speed syringe produ...

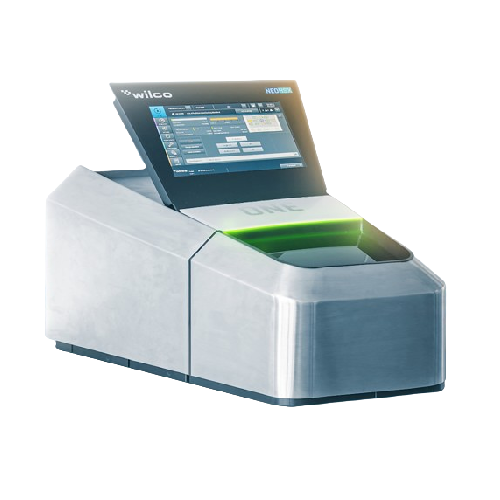

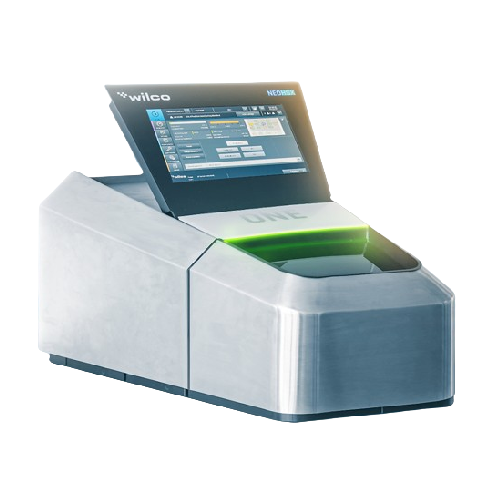

Lab headspace analyzer for small volume parenterals

Enhance your quality control with precise gas concentration measureme...

Headspace analyzer for small volume parenterals

Ensure precise gas concentration measurements in sterile pharmaceutical pa...

Headspace analyzing system for small volume parenterals

Ensure the integrity of sterile pharmaceuticals with precise head...

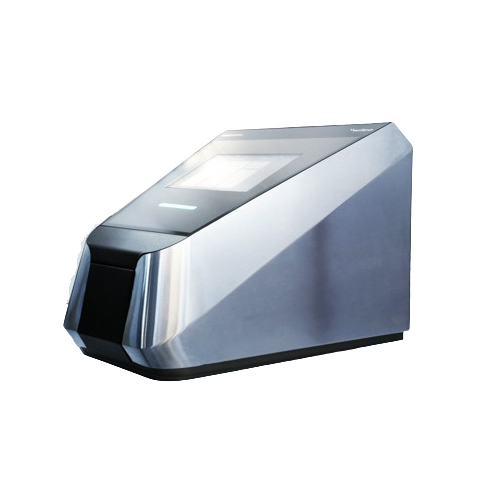

Automated container closure integrity tester

Ensure the integrity of your sterile pharmaceutical containers with high-spee...

Automated headspace analyzer for small volume parenterals

Optimize container closure integrity with high-speed, non-dest...

Blow/fill/seal packaging for laboratory and clinical trials

Streamline your small-scale pharmaceutical production with p...

Vial capping machine for pharmaceutical production

Ensure precise and reliable vial sealing in high-throughput pharmaceut...

Vial powder dispensing system

Optimize your aseptic fill process with high-precision powder dispensing that minimizes contam...

Superheated water sterilizer for pharmaceutical applications

Ensure precise sterilization with real-time monitoring and ...

Pharmaceutical autoclave for terminal sterilization

Optimize your sterile production with high-precision terminal sterili...

Washing machine for pharmaceutical rubber stoppers

Ensure sterile sealing and siliconization in rubber stopper processing...

Washing machine for pharmaceutical stoppers and caps

Streamline your aseptic processing with precise washing, sterilizati...

Sterilizing and depyrogenization tunnel for ampoules

Ensure sterile and pyrogen-free ampoules with precision control in d...

High-speed ampoule filling unit

Ensure precision and speed with this cutting-edge solution designed for efficient filling an...

Vial filling and stoppering system for aseptic production

Streamline aseptic production by integrating high-speed vial f...

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Feeding isolator for liquid preparation in pharmaceuticals

Ensure precise and contamination-free preparation of liquid p...

Active pharmaceutical ingredient isolation system

Ensure the aseptic production of pharmaceuticals while protecting perso...

Sterility testing isolator for aseptic environment

Ensure precise sterility testing and prevent contamination with an iso...

Hot press distilled water unit for pharmaceutical applications

Ensure superior water purity in pharmaceutical production...

Pure steam generator for pharmaceutical and biotech industries

Ensure optimal steam quality and compliance with stringen...

Aseptic blow fill seal system

Ensure sterile, high-speed production of liquid pharmaceuticals by integrating a cutting-edge ...

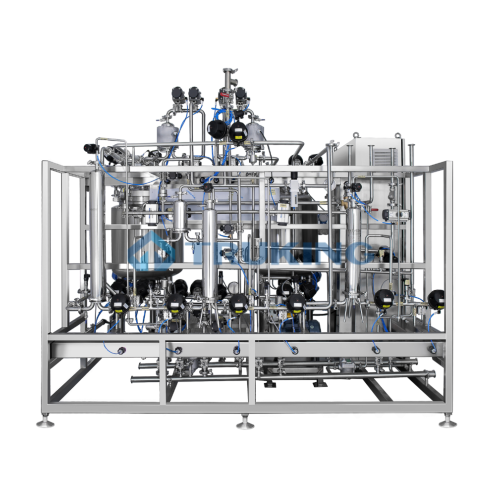

Production-level ultrafiltration system for industrial applications

Achieve precise concentration and separation of val...

Pharmaceutical preparation system

Achieve seamless integration in pharmaceutical processes with a preparation system that o...

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsul...

Comprehensive auxiliary system for online cleaning and temperature control

Ensure reliable and precise control in phar...

Isolator for sterility testing in pharmaceutical manufacturing

Ensure precise sterility testing with advanced isolators ...

Automatic inspection system for ampoules and vials

Ensure precision in pharmaceutical production with a comprehensive ins...

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

Automatic inspection system for sealing defects in ampoules

Ensure flawless ampoule sealing with a high-precision inspec...

Automatic inspection and leak test for pharma containers

Ensure container integrity for injectables with high-speed inspe...

Automatic leak detection system for pharmaceutical containers

Ensure the integrity of pharmaceutical containers with pre...

Sterilizing and drying tunnel for pharmaceutical vials

Ensure precise sterilization and depyrogenation of pharmaceutical ...

Vertical ultrasonic washing system for oral liquid bottles

Ensure optimal cleaning and sterilization with a compact vert...

Fully automatic hard capsule filling machine

Enhance pharmaceutical production with precise capsule filling, ensuring opti...

High-purity nitrogen generator for pharmaceutical and food industries

Achieve ultra-high purity levels in your producti...

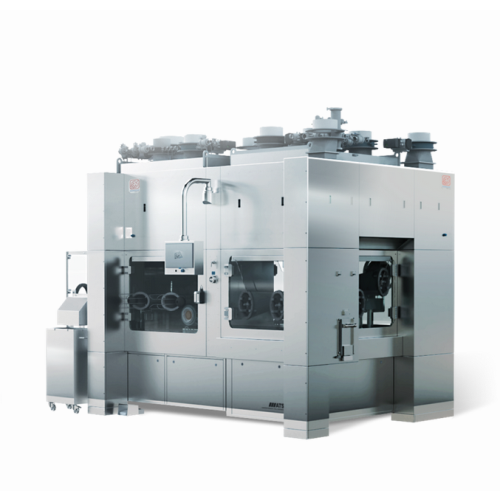

Industrial freeze dryer for pharmaceutical applications

Enhance your production line with precision cleaning solutions fo...

Sterilization and drying tunnel for glass bottles

Ensure aseptic integrity and regulatory compliance in injectable produc...

Gravity rotary filling for large infusion bottles

Ensure precise filling and secure stoppering of large infusion bottles ...

High capacity automatic blister packaging system

Streamline your production line with a high-speed blister packaging syste...

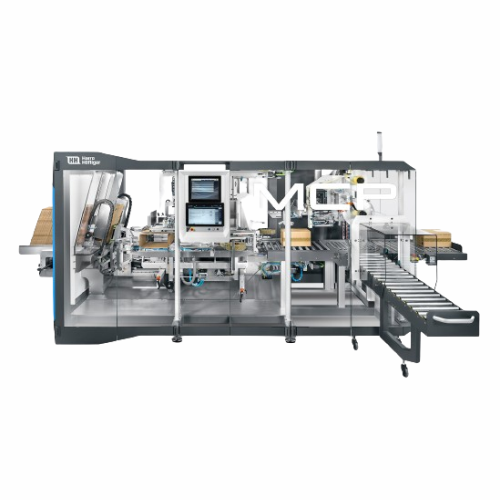

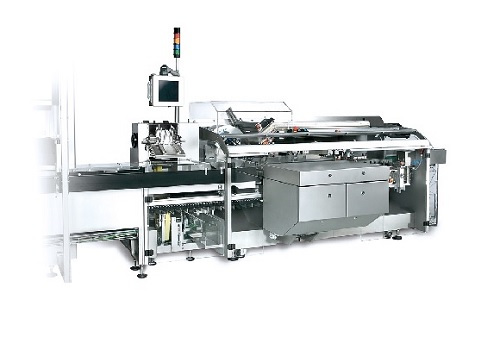

Secondary packaging cartoner for ampoules and vials

Optimize your aseptic production with efficient high-capacity carton ...

Automatic case packer for pharmaceutical industry

Optimize your packaging process with a versatile case packer designed t...

Pre-filled syringe plunger rod insertion and labeling system

Ensure precise labeling and efficient pre-filled syringe ha...

Large volume oral liquid filling system

Ensure precision and efficiency in liquid filling with a system designed to handle ...

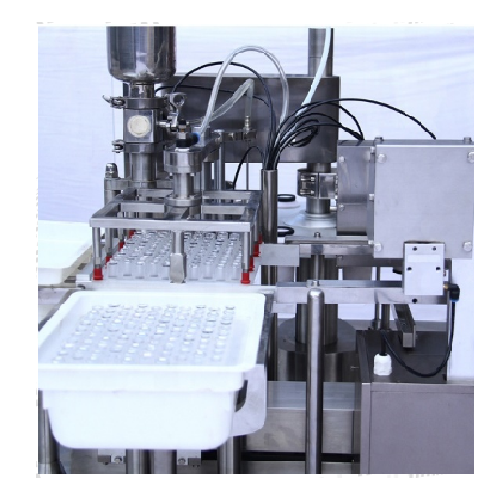

Diagnostic reagent filling system for accurate and efficient processing

Streamline the production of diagnostic reagent...

Industrial freeze dryer for pharma

Optimize moisture removal in lyophilized products with precise thermal conduction and ef...

Auto loading & unloading system for freeze dryers

Efficiently manage vial handling in freeze-drying processes with automa...

Mobile transfer loading system for freeze dryers

Streamline your lyophilization process with a high-capacity mobile loadin...

Laboratory freeze dryer for research and development

Optimize moisture removal with precision control during research and...

Ultrasonic pre-washing system for large infusion glass bottles

Optimize your cleaning process with an ultrasonic pre-was...

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for...

Steam & air mixture sterilizer for parenteral solutions

Achieve robust and effective sterilization for delicate pharmaceu...

Aseptic syringe filling isolator system

Ensure product sterility and precision with a cutting-edge solution for aseptic syr...

Two lyophiliser unloading isolators for hygroscopic products

Ensure precise moisture control and sterility for hygroscop...

Sterility test isolators for continuous batch testing

Ensure aseptic integrity during high-throughput sterility testing w...

Medical device assembly and labeling solutions

Streamline assembly and labeling processes for medical devices with technol...

Assembly solutions for medical devices

Optimize your medical device production with specialized assembly solutions that ens...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Steam air autoclave for pharmaceutical industry

Ensure precise sterilization of sensitive pharmaceutical products while ma...

Hydrogen peroxide vapor biodecontamination unit for cleanrooms

Ensure a sterile environment by effectively biodecontamin...

Pharmaceutical labeling for syringes and cartridges

Ensure precision and sterility in your labeling process with advanced...

Automatic syringe de-nester for pharmaceutical production

Streamline your syringe production line with high-speed de-nes...

Plastic bottle blowing-filling-sealing system

Optimize sterile liquid packaging with integrated blowing, filling, and seal...

Blow-fill-seal system for small volume injection production

Ensure precise aseptic liquid packaging with integrated blow...

Moist heat sterilizer for liquid preparation

Ensure precise sterilization of pharmaceutical liquids and injectable biologi...

Multi-lane sachet packaging machine

Optimize your packaging line with this multi-lane sachet packaging machine, designed to...

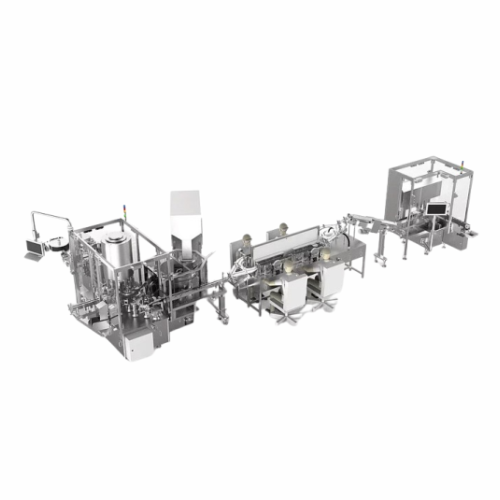

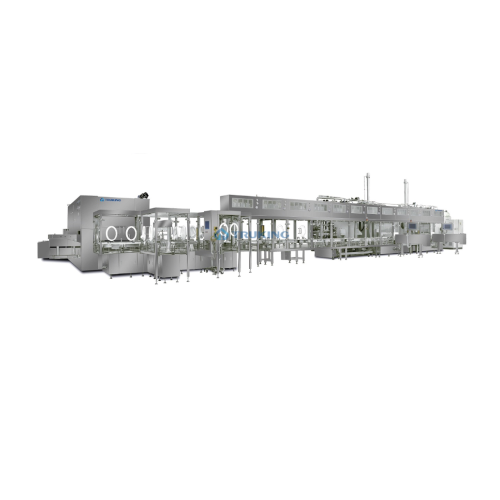

Intelligent pre-filled syringe production line

Optimize your sterile liquid medication production with a streamlined pre-f...

Automatic loading and unloading system for freeze-drying

Eliminate contamination risks and improve operational efficiency...

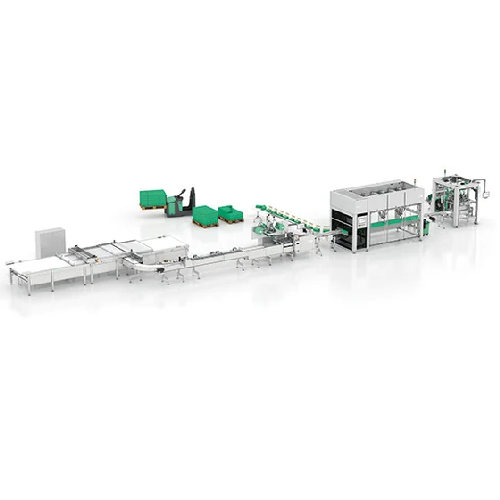

Modular assembly line for healthcare products

Assembly setups need to be constantly rethought and reconfigured to adapt qu...

Manual stoppering equipment for pre-filled syringes

Air present in the empty space of pre-filled syringes may prevent you...

R&D bottle washer

When you pack your products in bottles, vials, syringes, and test tubes you need to wash them before fillin...

Aseptic filling machine for liquids and powders

Aseptic filling of containers such as vials, syringes, bottles, and cartri...

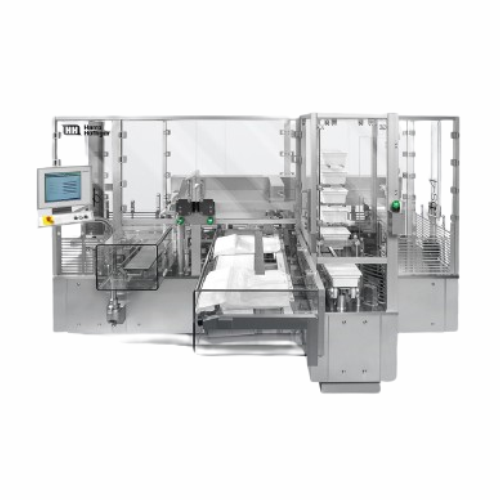

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

Automatic forming and sealing blister machine for packing syringes

Controlling contamination is on every manufacturer&#...

Cold forming aluminum blister machine for capsules

Aluminum blisters are mainly used for packaging products that are sens...

Easy to validate capsule filler

Staying competitive in today’s highly dynamic and highly regulated pharmaceutical prod...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Ethylene oxide sterilizer

When medical devices like syringes, catheters, dialysis cartridges, plastic dressings and sutures ...

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

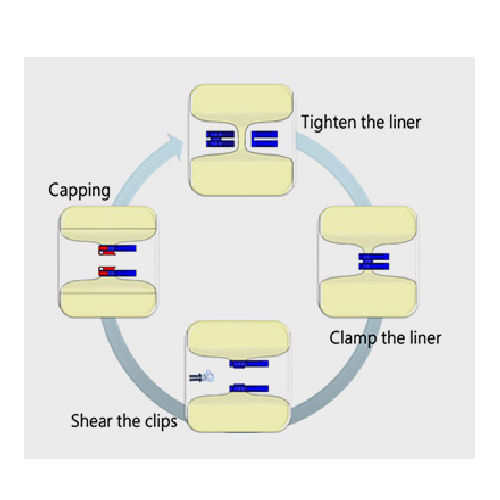

High containment closing system

Pharma and biopharma laboratories need fast effective solutions for tightly sealing bags for...

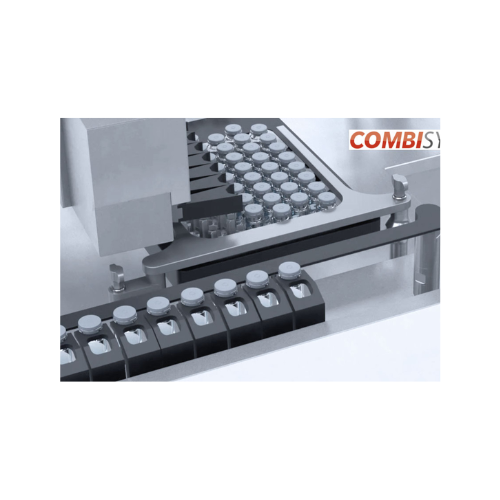

Packaging machine for syringes in trays

Pre-dosed syringes are rapidly becoming the method of choice for the delivery of in...

Entry-level blister packaging machine

Blister packaging is a popular packing method in the pharmaceutical industry thanks t...

Horizontal cartoner for pharmaceutical applications

Automatic cartoning for cosmetic or pharmaceutical products is a requ...

Start-up sterile filling line for injectables

For smaller-scale production of vials and syringes for the injectables marke...

Table top sterile filling line for injectables

Where a compact solution is required for filling vials for the injectables ...

Cleaning and sterilization systems

An increasingly vital part of high quality pharmaceutical production is a dedicated Clea...

Vial sterilization tunnel

Sterilization of vials, ampoules and syringes before filling is a vital step in the production of ...

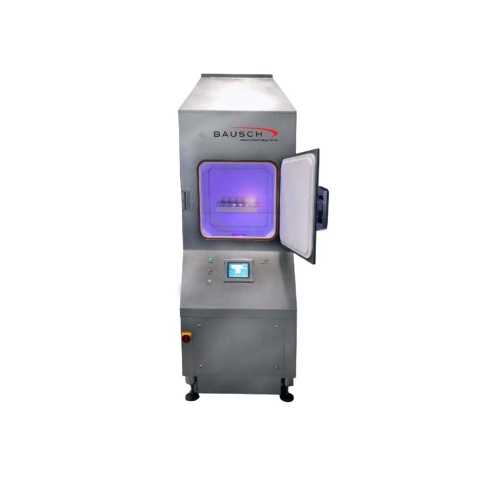

Syringe tub sterilizer

A common challenge is how to transfer nested syringe tubs to the aseptic filling area without compromi...

Sterile compounding system

Hospitals and compounding centres have traditionally used manual aseptic compounding processes. A...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Microencapsulation system for your drug delivery system

Whether you want to improve the stability of nutrients, protect a...

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

Flexible automatic inspection machine for ampoules, vials, cartridges

If you are looking to improve the efficiency of y...

Flexible automatic inspection machine for syringes

Manufacture of pre-filled syringes requires the highest quality inspec...

Small automatic inspector for ampoules, vials, or cartridges

Inspect small batch production of ampoules, vials, or cartr...

Semi-automatic inspection machine for ampoules, vials or cartridges

If you need to increase the efficiency of your manu...

Visual and HVLD inspection for ampoules, vials and cartridges

Do you need to improve the efficiency and capability of yo...

Filling and closing machine for parenterals

Any pre-filled syringe can be filled and closed with this fast and easy machin...

Bellows for pharmaceutical powders

Thermal and mechanical changes can lead to stresses in industrial piping systems. These ...

Sterile filling line for injectables

Sterile filling of liquids and powders for the pharmaceutical and cosmetic industries ...

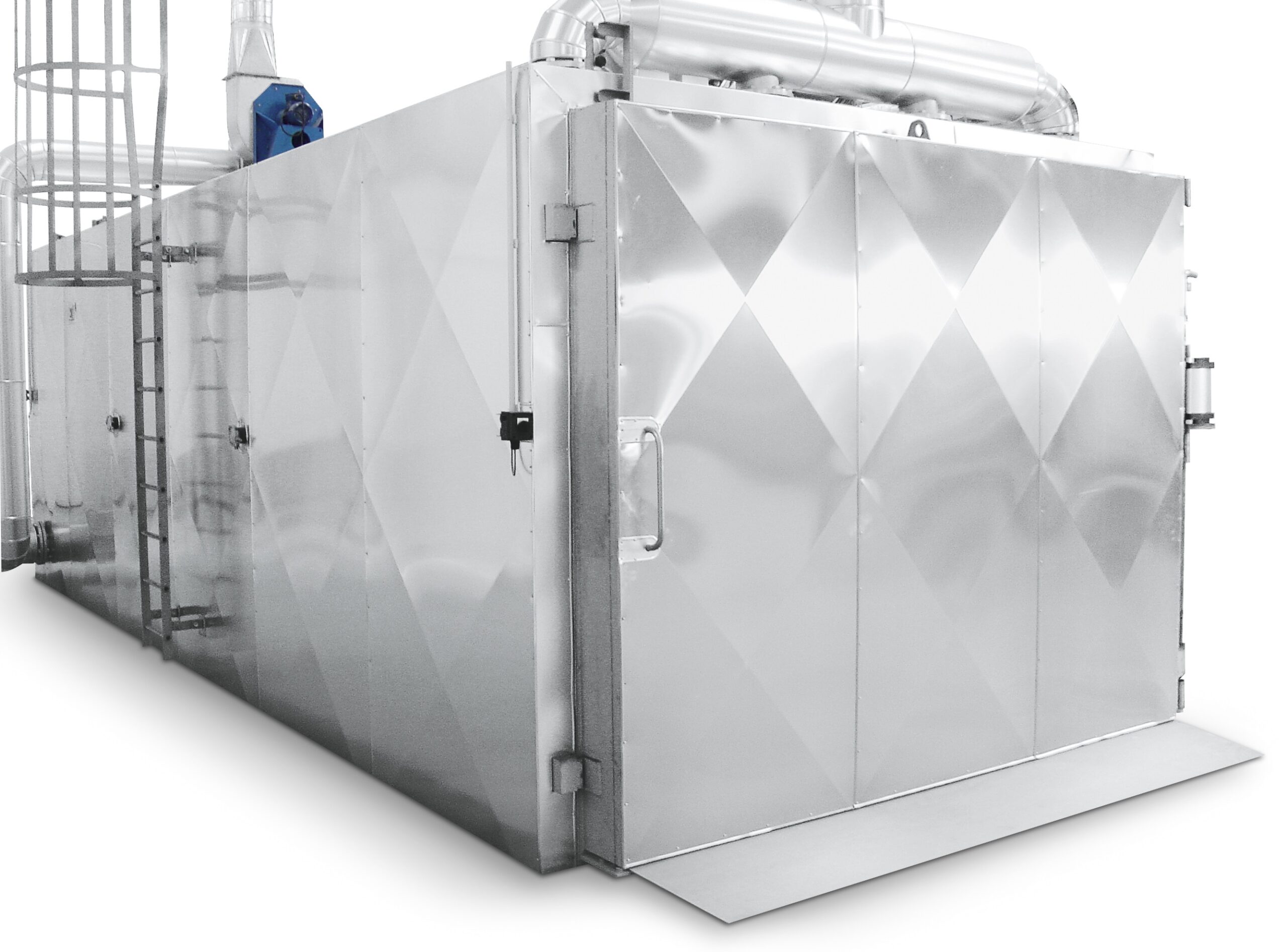

Ethylene oxide sterilization chamber

Designed for the terminal sterilization of temperature sensitive medical-health produc...

Sterility test isolators

Designed to avoid this risk and protect the product from both the process and externally generated f...

Flexible contained drum transfer system

Transferring powders from drums to process equipment such as reactors or mills can ...