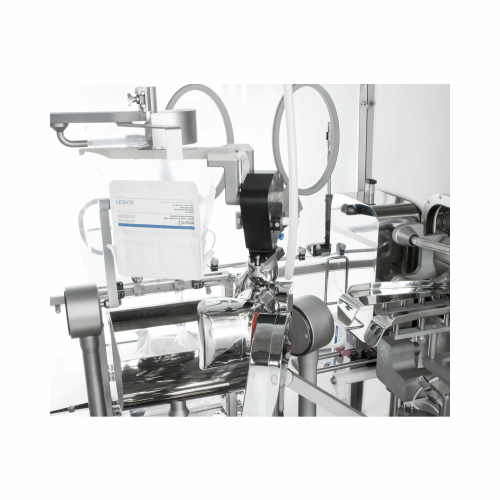

Robotic sterile package opening system

Achieve sterile precision with a fully robotic system that streamlines primary package opening, minimizing contamination risks and ensuring seamless handling in environments demanding rigorous aseptic standards.

Opens and Prepares Sterile Packages

The BAG OPENING AND TUB/TRAY OPENING system from IMA Life is designed for aseptic processing facilities looking for a fully automated solution to handle sterile packaging. It uses robotic technology to efficiently open and de-lid double-bagged packages, ensuring minimal risk of cross-contamination during processing. Commonly utilized in the pharmaceutical and biotech industries, this system processes sterile vials, lyophilized drugs, and other injectable forms with precision.

Operating with continuous automation, the system integrates seamlessly within high-speed production lines. It features restricted barrier systems (RABS) and complies with Annex 1 regulations, confining operations and preserving sterility through every phase. Components like the robotic cutting arm and de-lidding station are engineered for durability and precision, and the entire unit is adaptable to various container configurations. Maintenance is streamlined with an emphasis on reducing operational downtime, making the system integral for modern sterile packaging environments.

Benefits

- Enhances production efficiency by minimizing contamination risks with its fully automated, robotic process.

- Improves safety and compliance with Annex 1 regulations, ensuring a sterile environment throughout the operation.

- Decreases operational costs through reduced manual labor needs and faster processing times.

- Supports high-volume production with seamless integration into existing automated lines.

- Maintains sterility and product integrity with precision-controlled handling of double-bagged packages.

- Applications

- Biopharmaceuticals, Aseptic processing, Pharmaceutical packaging

- End products

- Biologic medications, Sterile ampoules, Unit-dose medication packs, Lyophilized drugs, Pre-filled syringes, Injectable drugs, Sterile vials, Vaccine doses

- Steps before

- Outer bag loading, Inner bag forming

- Steps after

- Decontamination, Tub de-lidding, Liner disposal, In-line downstream handling

- Input ingredients

- sterile primary package, outer bag, inner bag, tub, tray, single-use materials, TyvekTM lid, liner

- Output ingredients

- opened tub, opened tray, disposed outer bag, disposed inner bag, disposed TyvekTM lid, disposed liner

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Automation

- Fully automated

- Bag type

- Single or double bagged

- Capacity

- Medium-high production levels

- Cycle time

- Continuous process

- Robotic Technology

- Robotic cutting arm

- Bag handling

- Inner and Outer bag opening

- De-lidding process

- Robotic

- Compatibility with materials

- Single-use (TyvekTM lid and liner)

- Isolation method

- Restricted Barrier Systems (RABS)

- High-temperature resistant packaging

- Pre-heating option

- Cross-contamination control

- Yes

- Automation level

- Fully robotized

- Batch vs. continuous operation

- Inline Continuous

- Contamination control

- Reduced cross-contamination risks

- Isolation type

- Open/Closed RABS

- Production level suitability

- Medium-high production levels

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bag opening method

- Robotic cutting arm

- Tub/Tray de-lidding method

- Robotic de-lidding station

- Sterile package handling

- Fully automated robotized process

- Barrier system

- Restricted Barrier Systems (RABS)

- Waste disposal method

- Internal system disposal of single-use materials

- Production Level Suitability

- Medium-high production levels

- Bag Configuration

- Single or double bagged package

- De-lidding Process

- Robotic de-lidding station

- Transfer Method

- Internal transfer port

- RABS Configuration

- Open or closed RABS

- Decontamination Unit

- Optional after unwrapping

- Warming Station for Tub/Tray

- Pre-heated perimeter edge on request

- Suction Cups

- Used for bag flap opening