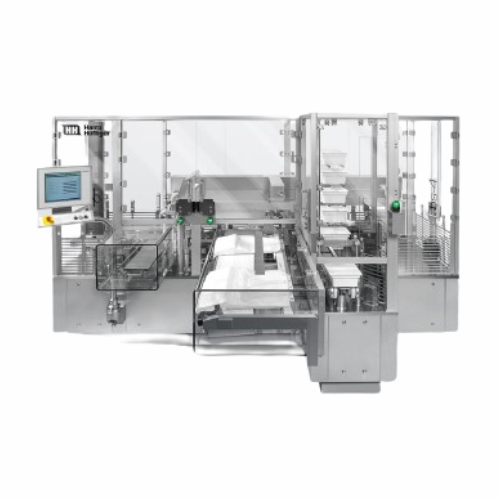

Double bagging solution for sealed tubs

Achieve sterile packaging for medical and pharmaceutical products with a compact, efficient double bagging process, ensuring contamination-free environments for sensitive applications.

Secures Sterile Packaging for RTF Products

The TBS Double Bagging Machine from Harro Höfliger ensures precise, sterile packaging of sealed tubs containing RTF syringes and vials using a compact, efficient design. This machine specializes in double-bagging with only one bag format, ideal for pharmaceutical and medical applications where aseptic conditions are paramount. Operating within ISO 7 clean rooms, the TBS handles vertically stacked Tyvek-sealed tubs, utilizing a mechanical sliding system for transferring tubs into opened bags. With a throughput of up to 4 single-bagged or 3 double-bagged tubs per minute, it supports low, mid, and high-speed operations. Integration into packaging lines is seamless, supporting various companion systems like labeling and control systems. Harro Höfliger’s TBS machine conforms to GMP standards, ensuring compliance with stringent industry regulations. It features aseptic bagging, which incorporates sophisticated sealing and cutting components to maintain sterility across small to large format applications. Customization options and engineering support ensure the machine fits specific production needs, maintaining sterility and product integrity.

Benefits

- Ensures product sterility by maintaining a germ-free packaging process in ISO 7 clean rooms.

- Increases efficiency with double-bagging capability without requiring additional bag formats.

- Seamlessly integrates into existing production lines, enhancing operational continuity.

- Reduces overhead with a compact design that fits restricted spaces.

- Enhances compliance with industry standards, supporting GMP requirements.

- Applications

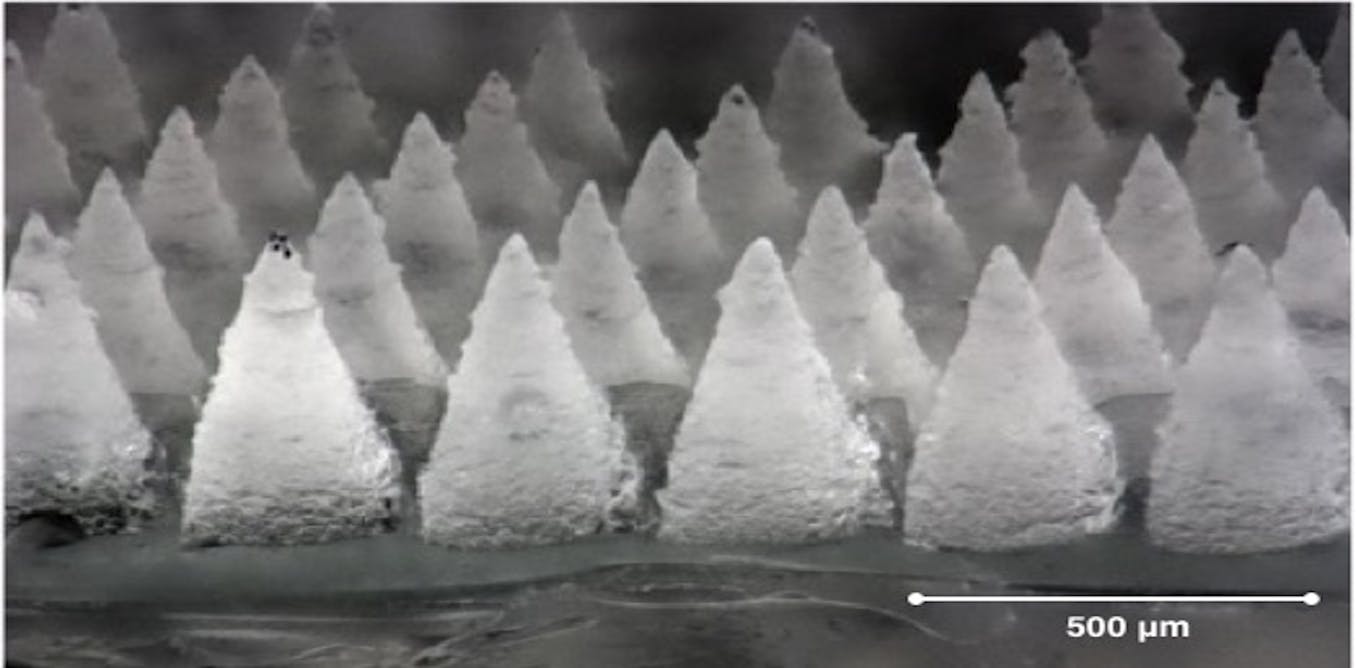

- Aseptic bags, Medical devices, Inhalation products, Rtf vials, Eye care products, Microneedles, Surgical sutures, Transdermal delivery systems, Oral delivery systems, Pharmaceutical products, Skin care products, Diagnostic products, Wound, Rtf syringes

- End products

- Inhalers, Vaccination vials, Nasal sprays, Sterile injection devices, Intradermal microneedle patches, Quick release tablets, Oral dissolving films, Nicotine patches, Sterile bandages, Hormone replacement therapy patches, Prefilled syringes, Contact lens solutions, Prepackaged surgical sutures, Hydrogel wound dressings

- Steps before

- Sterilization, Bag Preparation, Tub Sealing

- Steps after

- Packing, Labeling, Quality Control

- Input ingredients

- sealed tubs, vertically stacked tubs, RTF syringes, RTF vials, tyvek sealed tubs

- Output ingredients

- double-bagged tubs, single-bagged tubs, RTF syringes, RTF vials

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- 4 single-bagged tubs/min, 3 double-bagged tubs/min

- Cleanroom Classification

- ISO 7

- Bag type

- Double bagging with one bag format

- Working mechanism

- Intermittent double bagging

- Integrated steps

- Bag opening, tub insertion, bag sealing

- Batch vs. continuous operation

- Batch

- Automation level

- PLC-controlled

- Changeover time

- Quick bag format change

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- RTF syringes / RTF vials

- ISO Cleanroom Classification

- ISO 7

- Compact footprint

- Compact design

- Control panel type

- Touchscreen/Manual control

- Discharge method

- Mechanical sliding system

- Compact footprint

- Yes

- Control panel type

- HMI / PLC