Plastic bottle blowing-filling-sealing system

Optimize sterile liquid packaging with integrated blowing, filling, and sealing for high-volume pharmaceutical production. Elevate your line’s efficiency and ensure product integrity with seamless operations tailored for medical-grade bottles and containers.

Blow-Fills-Seals Sterile Liquid Containers

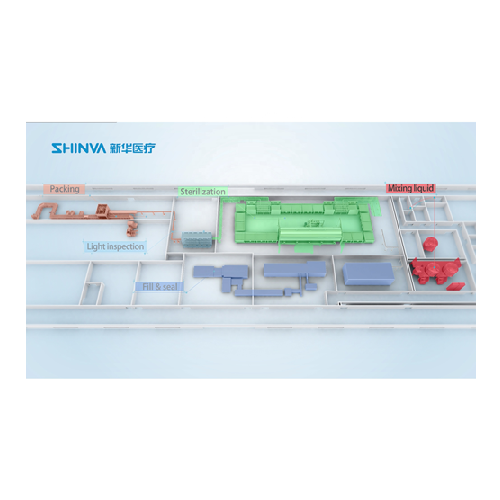

The Plastic Bottle Blow-Fill-Seal (BFS) Machine from Shinva Medical is a cutting-edge solution designed for pharmaceutical and medical device manufacturers requiring high-purity and contamination-free packaging. This specialized system integrates the blow, fill, and seal processes into a single, seamless operation, specifically tailored for sterile liquid containers, including PP infusion bottles and diagnostic reagent containers.

Operating on a continuous production line, it utilizes advanced PLC control with remote monitoring capabilities, ensuring precision and efficiency in high-speed production environments. The machine’s design emphasizes energy efficiency, reducing consumption by 20% through optimized motor control.

Constructed from corrosion-resistant materials, it meets stringent GMP and FDA standards, making it suitable for sterile and sensitive medical applications. Offering impressive throughput, it is capable of processing substantial volumes to meet the demands of large-scale manufacturing. Additionally, its integration capabilities allow seamless connectivity with existing production lines, from liquid preparation systems to packing logistics equipment.

Maintenance is simplified with an integrated Clean-In-Place (CIP) system, ensuring quick, thorough, and contamination-free cleaning. For those requiring specific operational adaptations, Shinva Medical supports customization and offers engineering assistance to tailor machine specifications to unique production needs.

Benefits

- Ensures contamination-free packaging, safeguarding product integrity and patient safety.

- Increases production efficiency with integrated blow-fill-seal operations.

- Minimizes operational costs with energy-efficient design, reducing consumption by 20%.

- Complies with GMP and FDA standards, ensuring regulatory adherence.

- Facilitates quick, efficient cleaning with an integrated CIP system, reducing downtime.

- Applications

- Medical consumables, Medical devices, Dental equipment, Infection control, Water making systems, Laboratory equipment, Pharmaceutical equipment, Biopharmaceuticals, In vitro diagnostics, Sterilization solutions, Surgical instruments, Injection solutions, Radiotherapy equipment

- End products

- Sterile water for injection, Blood sample tubes, Diagnostic reagent containers, Pp infusion bottles, Surgical instrument sterilization pouches, Iv bags, Oral medication bottles, Laboratory reagent bottles, Plastic medical vials, Pre-filled syringes, Dental impression trays, Dialysis fluid bags, Sterile saline solutions, Ophthalmic solution bottles

- Steps before

- Injection Molding, Liquid Preparation, Water Making

- Steps after

- Sterilization, Labeling, Packing, Palletizing

- Input ingredients

- PP material, preform, plastic pellets, water, labeling materials, cartons

- Output ingredients

- ISBM PP bottles, packed PP bottles, labeled PP bottles, sterilized PP bottles

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Bottle Blowing Machine

- N/A

- Injection Molding Machine

- N/A

- Wash-Fill-Seal Machine

- N/A

- Carton Erector

- N/A

- Liquid Preparation System

- N/A

- Water Making System

- N/A

- Palletizer

- N/A

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- N/A

- Tank Shape and Size

- N/A

- Feed Method

- N/A

- Discharge Method

- N/A

- Control panel type

- HMI/Touchscreen

- Integration possibilities

- SCADA/PLC

- Customization level

- Engineered-to-order

- Footprint customization

- Compact/Standard

- Operation mode

- Automatic/Manual