Headspace analyzing system for small volume parenterals

Ensure the integrity of sterile pharmaceuticals with precise headspace analysis and container closure integrity testing, ideal for improving safety in the packaging of sensitive products such as vaccines and injectable treatments.

Measures Gas Concentrations and Ensures Packaging Integrity

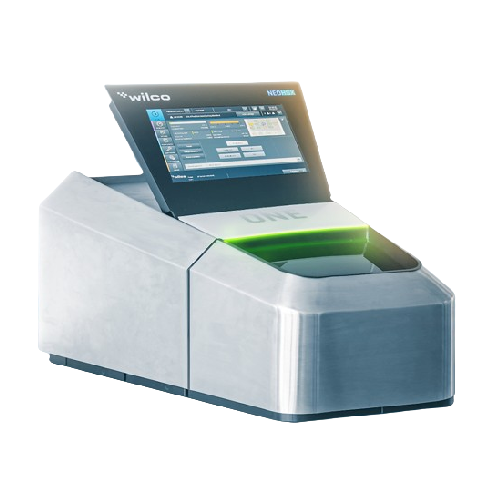

The NEO HSX Series by WILCO AG offers a sophisticated solution for headspace analysis in pharmaceutical and biopharmaceutical applications. Utilizing cutting-edge laser absorption spectroscopy, these analyzers precisely measure oxygen and carbon dioxide concentrations in sterile pharmaceutical packaging such as vials, syringes, and ampoules. The NEO HSX DUO, featuring dual laser heads, allows simultaneous O2 and CO2 detection, enhancing processing accuracy.

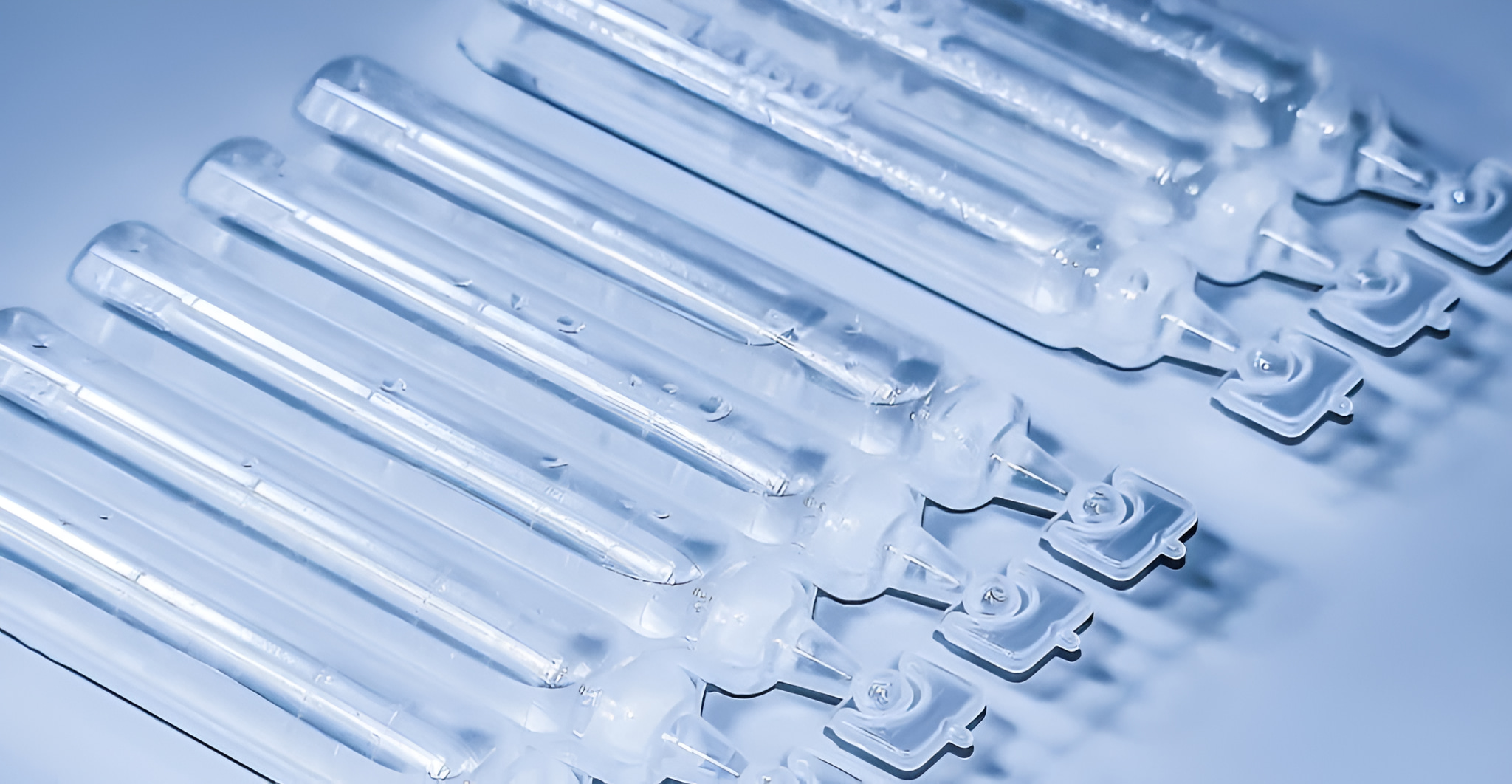

This series is integral to ensuring container closure integrity across various products, from vaccines to monoclonal antibodies and BFS nasal sprays. With the ability to process multiple packaging types manually or with robotic support, the NEO HSX Series accommodates capacities for vials ranging from 1 to 100 ml and syringes from 0.5 to 10 ml.

Automated via the MAVIS operating system, these analyzers offer intuitive user interaction and high operator friendliness, with features like exchangeable holders and position monitoring for maximum flexibility and process safety. The system’s plug-and-play sample holders and customizable interface enhance adaptability and process reliability.

Certified to meet GMP and FDA standards, the NEO HSX Series is 21 CFR part 11 compliant and designed for use in ISO Class 7 environments. With built-in UPS to prevent data loss and the ability to integrate with MES and SCADA systems, this equipment sets a benchmark in efficiency and compliance for quality control in sterile pharmaceutical productions.

Benefits

- Enhances measurement accuracy with up to 50% higher precision, ensuring product quality.

- Streamlines operations with intuitive MAVIS interface, minimizing user error and training time.

- Supports diverse packaging types, promoting operational flexibility and adaptability.

- Ensures compliance with GMP and 21 CFR part 11 standards, facilitating regulatory approval.

- Prevents data loss with integrated UPS, ensuring consistent and reliable quality control.

- Applications

- Bfs bottles, Syringes, Iv bags, Lyophilized vials, Bfs cards, Vials, Biopharmaceuticals, Ampoules, Sterile pharmaceuticals, Pharmaceutical packaging, Auto-injectors, Small volume parenterals, Large volume parenterals

- End products

- Bfs ophthalmic solutions, Antibiotic vials, Injectable hormonal treatments, Vaccines, Lyophilized protein drugs, Anticoagulant ampoules, Monoclonal antibodies, Bfs oral liquids, Chemotherapy drugs, Insulin pens, Iv saline solutions, Pre-filled syringes, Bfs nasal sprays, Contrast agents

- Steps before

- Development, R, D testing, Container preparation, Headspace conditioning, Sample loading

- Steps after

- Quality Control, Data analysis, Packaging, Storage, Distribution

- Input ingredients

- small volume parenterals, large volume parenterals, BFS cards, BFS bottles, IV bags, vials, ampoules, syringes, pharmaceutical packaging, compressed air, carbon dioxide, trace gases

- Output ingredients

- non-destructive measurement data, gas concentration data, oxygen analysis, carbon dioxide analysis, CCI testing results, inspection results, process safety validation, leak detection results

- Market info

- Laser Head Generation

- 4th generation

- Measurement Type

- Non-destructive gas concentration

- Measurement Lasers

- O2 and CO2

- Sample Size

- Vials 1 - 100 ml, Ampoules 1 - 20 ml, Syringes 0.5 - 10 ml

- Precision

- Up to 50% higher precision

- Display

- 12.1" color display

- Operation System

- MAVIS interface

- Compliance

- 21 CFR part 11

- Environment

- ISO Class 7

- Automation

- PLC system with MES and SCADA connectivity

- Operation Modes

- Development and GMP mode

- Process Reliability

- Position monitoring of sample holders

- Headspace Analysis

- Laser absorption spectroscopy

- Non-destructive Testing

- Yes

- Inspection Method

- Laser Absorption Spectroscopy

- Sample Types

- Vials, Syringes, Ampoules

- Automation Level

- Manual/Robot Supported

- Process Safety

- Position Monitoring System

- Operator Guidance

- Intuitive, MAVIS System

- Test Modes

- Development/GMP Area

- Changeover Flexibility

- Exchangeable Sample Holders

- Sensitivity Level

- High, 4th Generation Laser

- Compliance

- 21 CFR Part 11, ISO Class 7

- Batch vs. Continuous Operation

- Batch

- Energy Efficiency

- Integrated UPS

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Vials / Ampoules / Syringes

- Size range

- 1 ml – 100 ml

- Container Closure Integrity

- Leak detection

- Headspace gas analysis

- Oxygen / Carbon Dioxide

- Non-destructive testing

- Headspace Analysis

- Parenteral type

- SVP / LVP / BFS bottles / IV bags

- Laser type

- Single / Dual

- Automation level

- Manual / Robot-supported

- Testing mode

- GMP / Development

- Test method

- Headspace Analysis / Differential Pressure

- GMP Compliance

- Yes

- 21 CFR Part 11 Compliance

- Yes

- ISO Class 7 Certification

- Yes

- USP 1207 Compliance

- Yes

- Control panel type

- Intuitive MAVIS operation system

- Discharge method

- Manual / Robot supported

- Sample holder

- Exchangeable

- With position monitoring

- Laser configuration

- One or two laserheads for O2 and CO2

- Display size

- 12.1" color display

- Operation mode

- Desktop system

- Automation level

- Intuitive

- Operator-friendly

- Control panel type

- MAVIS operation system

- Interface customization

- Widgets for personalization

- Sample holders

- Exchangeable, position monitoring

- Inspection lasers

- Different wavelengths for O2 and CO2

- Recipe management

- Versioning and release