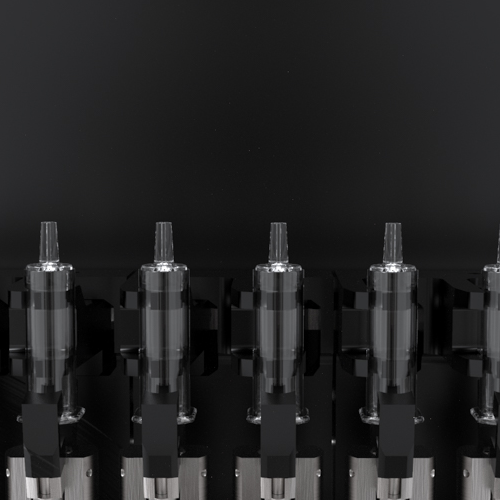

Syringe needle inspection module for pre-filled syringes

Ensure precise needle geometry with high-speed X-ray inspection, detecting defects such as bends and hooks in pre-filled syringes to maintain sterility and integrity.

Inspects Syringe Needles for Defects

The CUBE XRS 500 from WILCO AG is an X-ray-based inspection module designed for precise evaluation of syringe needle integrity in pharmaceutical manufacturing. This state-of-the-art equipment integrates high-resolution X-ray imaging with 360° sample rotation to detect defects such as bent needles and needle hooks. Catering to industries like pharmaceutical and biotech, it ensures the sterility and safety of pre-filled syringes used in applications like insulin and epinephrine auto-injectors. Operating at production speeds of up to 500 syringes per minute, the CUBE XRS 500 fits seamlessly into syringe production lines. Compliant with GMP guidelines, it supports data handling per 21 CFR part 11 and offers toolless format changeover, making it suitable for aseptic environments. The system’s ability to be integrated into WILCO’s Automated Visual Inspection (AVI) systems further enhances its versatility and ensures comprehensive quality control in sterile liquid pharmaceuticals production.

Benefits

- Ensures product safety and sterility through precise needle defect detection.

- Maximizes production efficiency with high-speed operation of up to 500 syringes per minute.

- Enhances quality assurance with 360° inspection and high-resolution imaging.

- Facilitates regulatory compliance with data handling standards adhering to 21 CFR part 11.

- Simplifies maintenance and reduces setup time with toolless format changeover.

- Applications

- Medical devices, Iv bags, Lyophilized products, Sterile liquid pharmaceuticals, Parenterals, Pre-filled syringes, Auto-injectors, Pharmaceuticals

- End products

- Insulin pre-filled syringes, Lyophilized vaccines, Iv saline bags, Lyophilized chemotherapy drugs, Growth hormone pre-filled syringes, Epinephrine auto-injectors, Blood plasma iv bags, Antibiotic syringes, Biologics auto-injectors, Lyophilized protein therapeutics, Heparin auto-injectors, Nutrient iv bags

- Steps before

- Pre-filled syringe assembly, Needle attachment

- Steps after

- Final assembly inspection, Sterilization, Packaging

- Input ingredients

- pre-filled syringes, syringe needles

- Output ingredients

- 360° high-resolution images, inspection results, analyzed needle geometry, detection of bent needles, detection of needle hooks

- Market info

- Inspection Speed

- Up to 500/min

- Inspection Type

- X-ray

- Image Resolution

- High-resolution

- Rotation Angle

- 360°

- Syringe Sizes

- Multiple

- Detection Capabilities

- Bent Needles, Needle Hooks

- Compliance

- 21 CFR Part 11

- Design Standard

- GMP

- Automation

- Image Processing Algorithms

- Area of Use

- Aseptic Area

- Working Mechanism

- X-ray based inspection

- Integrated Steps

- 360° rotation and image capture

- Batch vs Continuous Operation

- Inline Continuous

- Automation Level

- PLC Controlled

- Cleaning Method

- Designed for use in aseptic area

- Line Integration

- Syringe production line integration

- Data Handling

- Compliance with 21 CFR part 11

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- Designed according to GMP guidelines

- 21 CFR Part 11 Compliance

- Data Handling in compliance with 21 CFR part 11

- Inspection type

- X-ray

- 360° inspection

- Yes

- Output rate

- Up to 500/min

- Applicable for syringe sizes

- Multiple

- Integration capability

- Line integration

- Toolless format changeover

- Yes

- Integration possibilities

- Line integration

- Inspection method

- X-ray based

- Sample rotation capability

- 360°

- Image processing tools

- High-resolution, latest algorithms

- Output capacity

- Up to 500/min