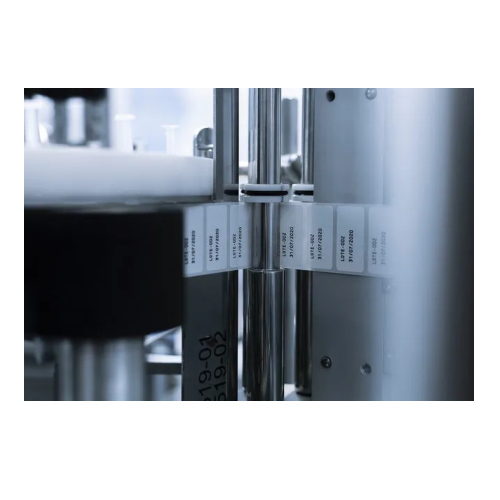

Pharmaceutical labeling for syringes and cartridges

Ensure precision and sterility in your labeling process with advanced dual-function robotics, seamlessly integrating plunger insertion and labeling to maintain consistency and compliance in high-speed, continuous operations.

Inserts Plungers and Labels Syringes

The Hull i-Dositecno SY Pharmaceutical Labeling Machine from i-Dositecno offers an integrated solution for pharmaceutical and biotech manufacturers needing precision in plunger insertion and syringe labeling. Its dual function robotics, combined with servo-driven star wheel technology, ensures high-speed operation without compromising on sterility, essential for producing prefilled syringes and injectables. Engineered to handle up to 6,000 units per hour, it is designed for seamless incorporation within processing and packaging lines, equipped with Siemens or Allen Bradley PLCs for customizable output. The machine supports ready-to-use (RTU) syringes and cartridges, enhancing operational flexibility. Adhering to cGMP, Annex 1, and 21 CFR Part 11 standards, it also features a Staubli Stericlean robot for hydrogen peroxide decontamination, ensuring compliance and safety. Its compact, cleanroom-ready design allows for easy integration with RABS and isolation technology, backed by optional mechanical and validation support from ATS Scientific Products, guaranteeing optimal performance and regulatory compliance.

Benefits

- Enhances production efficiency with high-speed plunger insertion and labeling.

- Ensures product sterility and safety through advanced decontamination capabilities.

- Simplifies compliance with industry standards including cGMP and 21 CFR Part 11.

- Enables seamless integration with existing RABS and isolation systems.

- Customizable for various syringe and cartridge configurations, increasing operational flexibility.

- Applications

- Biopharmaceuticals, Liquid formulations, Human injectables, Pharmaceuticals

- End products

- Biologic injectables, Ready-to-fill vials, Sterile liquid medications, Prefilled syringes, Injectable drug cartridges

- Steps before

- Filling, Assembly

- Steps after

- Sterilization, Packing, Distribution

- Input ingredients

- syringes, cartridges, plungers, ready-to-fill (SCF) tubs, RTU components

- Output ingredients

- labeled syringes, labeled cartridges

- Market info

- Speed

- Up to 6, 000 units per hour

- Compliance

- 21 CFR Part 11, cGMP, Annex 1, GAMP5

- Robot Type

- Staubli Stericlean robot

- Automation

- PLC-controlled

- Components

- Ready-to-use (RTU) syringes and cartridges

- Software

- Dual function robotics

- Cleaning Method

- Hydrogen peroxide decontamination

- Capacity

- Syringe and cartridge filling

- Load capacity per hour

- Up to 6, 000 units per hour

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Changeover time

- Fast

- CIP/SIP

- Sterile conditions ready

- Cleaning method

- Compatible with cleanroom

- GMP Compliance

- Yes

- 21 CFR Part 11 Compliance

- Yes

- IQ/OQ Validation Packages

- Available

- CGMP Compliance

- Yes

- Annex 1 Compliance

- Yes

- GAMP5 Compliance

- Yes

- Machine footprint

- Compact

- Control panel type

- Siemens or Allen Bradley PLC

- Cleanroom compatibility

- Yes

- Discharge method

- Automatic with servo-driven star wheel

- Control panel type

- Siemens or Allen Bradley PLC

- Integration possibilities

- Open RABS, Closed RABS, Isolation Technology