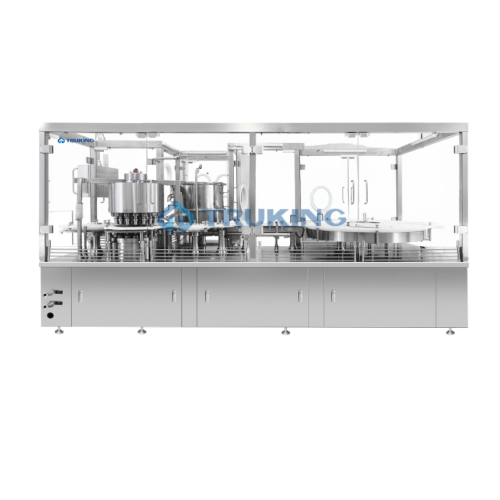

Vial capping machine for pharmaceutical production

Ensure precise and reliable vial sealing in high-throughput pharmaceutical production lines, maintaining strict regulatory compliance while maximizing efficiency and minimizing operational footprint.

Caps and Seals Pharmaceutical Containers

The TRUKINGZG Series from TRUKING Technology is an industrial pharmaceutical capping machine engineered for high-efficiency and precise container sealing. It employs an advanced suction system to maintain a contamination-free environment, crucial for injectable and oral liquid preparations. With the ability to support a throughput of 36,000 units per hour, this capping machine ensures high-speed operation, suited for demanding production lines involving vaccines and diagnostic reagents. Equipped with an automatic turret for quick adjustments, it facilitates seamless integration with various filling lines—such as SVP, LVP, and BFS systems—allowing for smooth transitions in dynamic environments. Constructed from stainless steel SS 316L, it guarantees enhanced cleaning with no dead angles and offers superior resistance to corrosion, making it ideal for diverse pharmaceutical applications. Additionally, the system is compliant with GAMP and cGMP regulations, ensuring adherence to industry standards. TRUKING’s in-house engineering provides customizable options with O-RABS and C-RABS, supporting stringent containment requirements (up to OEL 5) for optimal safety and performance.

Benefits

- Enhances production efficiency by sealing up to 36,000 units per hour.

- Minimizes contamination risks with a specialized aluminum particle suction system.

- Facilitates rapid production line changes with automatic turret adjustments.

- Ensures compliance with strict pharmaceutical regulations, including GAMP and cGMP.

- Optimizes cleanroom space with a compact, modular design.

- Applications

- Injectable, Oral liquid preparations, Lyophilization, Softbag production, Bfs production, Pre-filled syringe production, Ampoule production, Chinese traditional medicine, Diagnostic reagents

- End products

- Oral suspension antibiotic, Vaccines, Pre-filled insulin syringes, Large volume parenterals, Traditional chinese medicine tonic, Diagnostic test kits, Herbal extracts, Freeze-dried pharmaceuticals, Ampoules with saline solution, Blister-packed saline vials

- Steps before

- Vial Washing, Ultrasonic Washing, Drying, Preparation, Extraction, Concentration

- Steps after

- Sterilizing, Packaging, Capping, Inspection, Leakage Testing

- Input ingredients

- ampoule, vial, pre-filled syringe, soft bag, glass bottle, plastic bottle, liquid, freeze drying content

- Output ingredients

- lyophilized product, sterilized vial, sealed ampoule, finished pre-filled syringe, sealed soft bag, sealed glass bottle, sealed plastic bottle, sterilized and capped products

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Automatic Turret motorized adjustment

- Containment Level

- OEL 5

- Footprint Design

- Compact

- Material Contact Design

- SS 316L

- Particle Suction Device

- Aluminum particle suction through vacuum

- Performance

- High throughput of 36000 units per hour

- Regulatory Compliance

- GAMP, cGMP, FDA

- Cleaning Design

- No dead angles

- Control System

- Industrial PC

- Leak Rates

- Optimum

- Modular Customization

- Yes

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Customizable

- FDA materials

- Yes

- SS 316L Product Contact

- Yes

- Compact footprint

- Yes

- Control panel type

- Industrial PC control

- Discharge method

- Automatic

- Footprint

- Compact

- Ergonomic design

- Minimum footprints

- Material contact design

- SS 316L

- Control panel type

- Industrial PC control

- Integration possibilities

- O-RABS, C-RABS, and Isolators

- Compact footprint

- Modular customization to save cleanroom space

- Automation features

- Turret motorized adjustment, remote access, data integrity compliance

- Containment level

- OEL 5 for C-RABS and Isolator