Automatic tub opening and denesting module

Optimize sterile vial processing by efficiently opening and denesting tubs for seamless integration into high-speed pharmaceutical production lines.

Opens and Denests Pharmaceutical Tubs

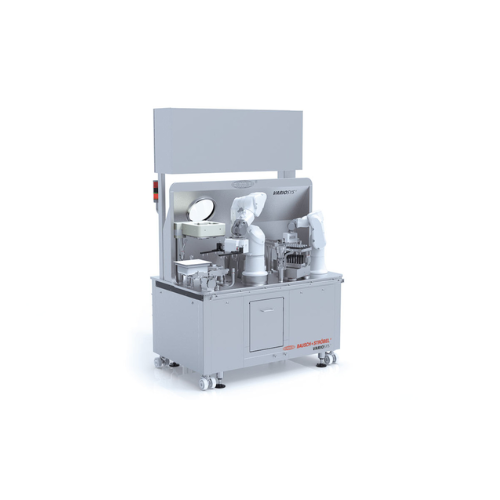

The DDM 9105 from Bausch+Ströbel is a fully automatic module specifically designed for precision tub opening and denesting in pharmaceutical and biotech production environments. Utilizing a patented heating frame, the module efficiently loosens adhesive bonds, ensuring a particle-reduced process ideal for laminar flow environments. Capable of processing up to 60 tubs per hour, it caters to ready-to-use vials, nested containers, and liquid formulations, making it essential for manufacturing sterile injectable vials, pre-filled syringes, and vaccine vials. Seamlessly integrating with upstream and downstream processes, the DDM 9105 operates within a mobile, space-saving isolator system, enabling centralized control and optimal laminar airflow. Optional features like free-standing vacuum pumps and mobile collection bins enhance its versatility, while compliance with pharmaceutical standards guarantees reliability and safety in critical applications.

Benefits

- Enhances productivity by efficiently processing up to 60 tubs per hour.

- Ensures product integrity with particle-reduced handling and optimal laminar airflow.

- Minimizes operational footprint with a mobile, space-saving design.

- Boosts flexibility with optional equipment like vacuum pumps and collection bins.

- Maintains compliance with rigorous pharmaceutical standards for safety and reliability.

- Applications

- Nested containers, Liquid formulations, Biopharmaceuticals, Ready-to-use vials, Pharmaceuticals

- End products

- Cancer treatment vials, Nested vial packs, Pre-filled syringes, Sterile injectable vials, Vaccine vials, Antibody vials, Blood plasma bags, Hormone vials

- Steps before

- Tub debagging

- Steps after

- Further processing in bulk, Downstream processing, Sterilization, Packing

- Input ingredients

- tubs, RTU vials, nested containers

- Output ingredients

- opened tubs, denested vials, nest on transfer track

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- Up to 60 tubs/h

- Processing Range

- Nested containers

- Automation

- Fully automatic

- Cleanroom Compatibility

- Laminar air flow

- Heating Method

- Heating frame

- Particle Reduction

- Reduced particle process

- Automation level

- Fully automatic

- Changeover time

- Quick changeover capability

- Batch vs. continuous operation

- Batch

- Cleaning method

- Optimized for laminar flow

- Energy efficiency

- Optimized design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- RTU vials, Nested containers

- Modular system

- VarioSys production system

- Compact footprint

- Mobile, space-saving

- Control panel type

- Easy and centralized operation

- Discharge method

- Robot-assisted transfer

- Control panel type

- Centralized

- Compact footprint

- Mobile, space-saving

- Integration possibilities

- Seamless VarioSys system integration

- Transfer track customization

- Optional

- Vacuum pump customization

- Free-standing

- Collection bin customization

- Mobile