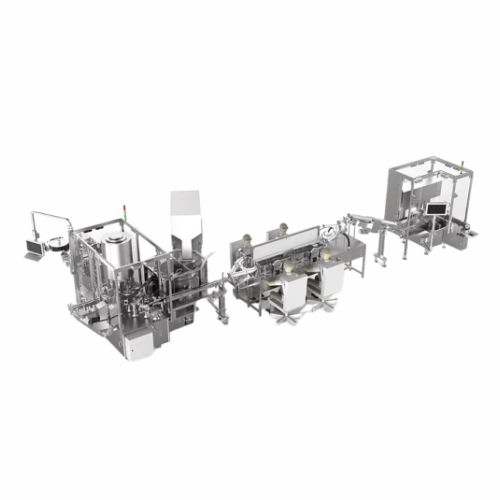

Syringe assembly system for plunger rod, label, and safety device

Ensure precise handling and assembly of pharmaceutical syringes with modular systems for plunger rods, labeling, and safety devices, streamlining your workflow for seamless production.

Assembles and Inspects Pharmaceutical Syringes and Containers

Groninger’s Syringe Assembly Machines offer an integrated solution for the precise assembly and inspection of pharmaceutical primary packaging, including syringes, vials, and cartridges. These machines excel in handling delicate processes such as plunger rod insertion, labeling, and safety device assembly, ensuring the integrity of prefilled syringes used for a range of medical applications, from insulin delivery to vaccination. Capable of processing up to 600 objects per minute, these machines boast a modular design that allows for easy line integration and expansion with features like backstop mounting and advanced inspection systems. Their electromotive mechanisms ensure minimal energy consumption while maintaining high precision assembly. Stainless steel construction provides durability and compliance with GMP and FDA standards. Cleaning is simplified with an integrated tray loading and buffering system, complemented by comprehensive engineering support for customization to meet specific production requirements.

Benefits

- Ensures product integrity with non-contact transfer and precise assembly.

- Enhances production flexibility with modular and customizable design.

- Increases efficiency with high-speed processing of up to 600 objects per minute.

- Minimizes errors through advanced inspection and labeling systems.

- Complies with GMP and FDA standards, ensuring regulatory adherence.

- Applications

- Vials, Ready-to-use syringes, Vial filling, Cartridges, Prefilled syringes, Aseptic filling, Cartridge filling, Pharmaceutical primary packaging

- End products

- Pediatric dosing syringes, Insulin prefilled syringes, Antibiotic vials, Vaccination vials, Biologic drug cartridges, Hormone therapy cartridges, Pain management prefilled syringes, Chemotherapy vials, Anticoagulant prefilled syringes, Emergency medication cartridges

- Steps before

- Washing, Sterilizing, Filling, Tray Loading, Buffering

- Steps after

- Inspection, Labeling, Safety Device Assembly, Packing

- Input ingredients

- syringes, vials, cartridges, plunger rods, labels, safety devices, backstops, finger flanges

- Output ingredients

- assembled syringes, labeled pharmaceutical packaging, pre-filled syringes with safety components, processed primary packaging

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Automation

- Modular, PLC-controlled

- Speed

- Up to 600 objects per minute

- Capacity

- 3 in 1 processing of syringes, vials, cartridges

- Inspection methods

- Sensors/image processing systems

- Labeling process

- Integrated removal of bad labels

- Plunger Rod Assembly

- Patented electromotive

- Safety Device Assembly

- Modular expansion

- Handling Systems

- Feeding, tray loading, buffering

- Printer Integration

- Integration of all common printers

- Splicing Unit

- Automatic at full capacity

- Automation level

- High-speed / Semi-automated

- Batch vs. continuous operation

- Modular / Inline Continuous

- Changeover time

- Minimal due to modular design

- CIP/SIP

- Non-contact cleaning

- Energy efficiency

- Optimized for high throughput

- Cleaning method

- Non-contact / Gentle handling

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Regular pharmaceutical powder and liquid

- Compact footprint

- Modular and compact design

- Discharge method

- Non-contact transfer system

- Control panel type

- Customizable HMI

- Integration possibilities

- Modular expansion for process modules

- Compact footprint

- Yes