Moisture and pressure headspace analysis for sealed parenteral containers

Ensure accurate moisture and pressure assessment in sealed parenteral containers to optimize your lyophilization processes and verify container closure integrity effortlessly.

Non-Destructively Analyzes Moisture and Pressure

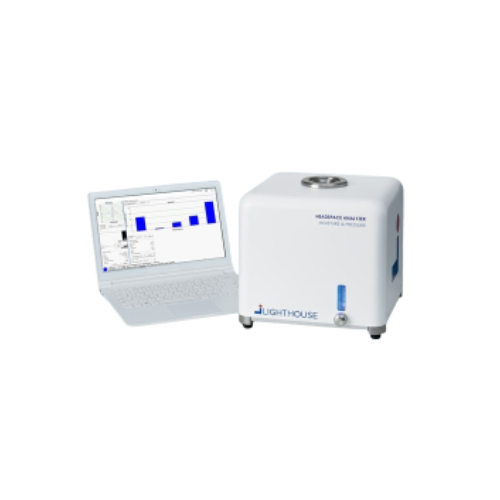

The FMS-Moisture/Pressure Headspace Analyzer from Lighthouse Instruments stands out for its ability to non-destructively monitor moisture partial pressure and total pressure within sealed parenteral containers. This benchtop analyzer excels in applications such as vacuum leak detection and moisture determination for pharmaceuticals, biologics, and lyophilized products. It effectively bridges critical phases of the product life cycle, enhancing product quality and integrity. The analyzer features a measurement range from 0 to 25 torr moisture and up to 1 atm total pressure. Designed for integration in laboratory and processing departments, it accommodates various container types, including syringes, vials, and ampoules, in clear and amber configurations. The equipment supports 21 CFR Part 11 compliance, ensuring adherence to industry standards, and offers configurable options for different diameters, making it versatile for diverse use cases. Additionally, its PLC-controlled system enables seamless integration and operation within automated environments, while adhering to stringent compliance standards essential for pharmaceutical manufacturing.

Benefits

- Ensures product integrity by accurately monitoring moisture and pressure non-destructively.

- Enhances quality assurance through effective vacuum leak detection and container closure integrity testing.

- Reduces compliance risks with 21 CFR Part 11 software for secure data handling.

- Adapts to various container types, facilitating flexible testing scenarios.

- Streamlines operations with seamless integration into automated environments.

- Applications

- Freeze-dried products, Lyophilized products, Dry product, Parenteral containers, Pharmaceuticals

- End products

- Freeze-dried vaccines, Reconstituted antibiotics, Hormone injectables, Injectable medications, Lyophilized protein formulations, Pre-filled syringes, Biologics in ampoules, Parenteral nutrition solutions, Freeze-dried coffee, Dry powder inhalers

- Steps before

- Container sealing, Lyophilization, Dry product preparation

- Steps after

- Vacuum leak detection, Container closure integrity studies, Moisture degradation studies, Packing

- Input ingredients

- sealed parenteral containers, dry product, lyo product, syringes, ampoules, vials, bottles

- Output ingredients

- moisture partial pressure, total pressure, residual moisture content

- Market info

- Lighthouse Instruments is known for its expertise in providing high-precision laser-based inspection and measurement systems, primarily for the pharmaceutical industry, specializing in non-destructive testing solutions for ensuring container integrity and product quality.

- Required Headspace

- 3mm

- Measurement Range (Total Pressure)

- 0 to 1 atm (0 to 760 torr)

- Measurement Range (Moisture)

- 0 to 25 torr

- Configuration Sizes

- 6.85mm to 86mm outer diameter

- Software Compliance

- 21 CFR Part 11 and Annex 11 compliant

- Glass Type

- Tubing, Molded, and Plastics

- Color Type

- Clear and Amber

- Operating Mode

- Batch / Non-destructive

- Automation Level

- 21 CFR Part 11, Annex 11 Compliance

- Measurement Capability

- Moisture Partial Pressure, Total Pressure Monitoring

- Operating Environment

- Syringes, Ampoules, Vials, and Bottles

- Pressure Range

- Total Pressure 0 to 1 atm (0 to 760 torr)

- Glass Type

- Tubing, Molded, Plastics

- Color Type

- Clear, Amber

- Configuration Type

- Syringes, Ampoules, Vials, Bottles

- 21 CFR Part 11 compliance

- Yes

- Annex 11 compliance

- Yes

- Glass Type

- Tubing, Molded, Plastics

- Color Types

- Clear, Amber

- Required Headspace

- 3mm

- Configuration Types

- Syringes, Ampoules, Vials and Bottles

- Configuration Sizes

- 6.85mm to 86mm outer diameter

- Color Types

- Clear and amber

- Glass Types

- Tubing, molded and plastics