Soft bag form-fill-seal system for large volume injection

Streamline your production of intravenous and nutritional fluids with an efficient form-fill-seal system, ensuring precise bag forming, filling, and sealing while maintaining sterility and reducing contamination risks.

Forms, Fills, and Seals Soft Bags

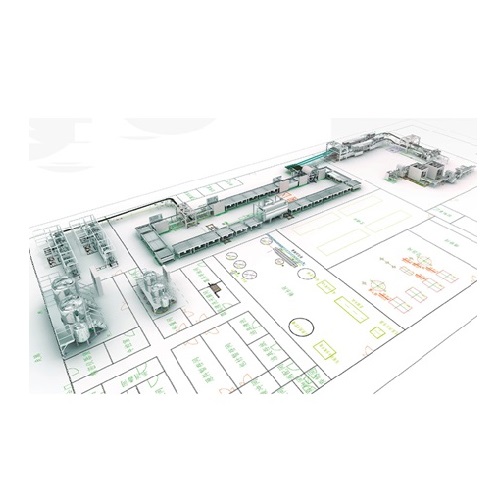

The Soft Bag FFS Machine from Shinva is engineered for pharmaceutical manufacturers requiring efficient production of large volume injections. It specializes in forming, filling, and sealing soft bags in a seamless process, ensuring sterile intravenous saline, dextrose, and nutritional bags. This machine operates on a continuous, automatic production line with a PLC-controlled system for precise, high-volume output.

Capable of integrating with upstream sterilization systems and downstream packing, palletizing, and warehousing steps, it offers a complete turnkey solution. Its energy-efficient design minimizes utility consumption, while sophisticated inspection systems ensure each product meets stringent quality standards.

Constructed from corrosion-resistant materials, the machine is GMP and FDA compliant, supports CIP (Clean-In-Place) for hygienic operations, and can be tailored to specific production needs with customizable configurations.

Benefits

- Enhances production efficiency with continuous, streamlined bag forming and filling.

- Cuts operational costs by integrating energy-saving features.

- Ensures product sterility and safety through seamless sealing and inspection processes.

- Facilitates compliance with GMP and FDA regulations for pharmaceutical manufacturing.

- Minimizes labor input with automated, PLC-controlled operation.

- Applications

- Soft bag form-fill-seal, Dental equipment, Laboratory equipment, Pharmaceutical equipment, Radiotherapy solutions, In vitro diagnostics, Large volume injections, Medical device manufacturing, Surgical instruments, Biosafety solutions

- End products

- Medical diagnostic kits, Sterilization pouches, Nasal cannulas, Orthopedic surgical kits, Hemodialysis filters, Radiopharmaceuticals, Dental autoclaves, Intravenous saline bags, Dextrose injection bags, Endotracheal tubes, Sterile packaging containers, Dental units, Chemotherapy bags, Nutritional iv bags, Antibiotic injection bags, Capillary dialyzers

- Steps before

- Water preparation, Bag form-fill-seal preparation

- Steps after

- Sterilization, Water removal, Light inspection, Packing, Palletizing, Warehousing

- Input ingredients

- water, medical-grade polymers, sterilization agents, packaging materials

- Output ingredients

- large volume injection solutions, filled soft bags, sterilized products, packaged medical instruments

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Automation

- PLC-controlled

- Bag type

- Soft Bag FFS

- Filling speed

- 10k–150k/hr

- Filling volume

- 1 ml – 5 L

- Sterilization method

- Autoclave

- Water system

- Included

- Palletizing system

- Automatic

- Light inspection system

- Integrated

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP / SIP

- Cleaning method

- CIP / Manual

- Integrated steps

- Form-fill-seal, Sterilization, Packaging

- Working mechanism

- Form-fill-seal