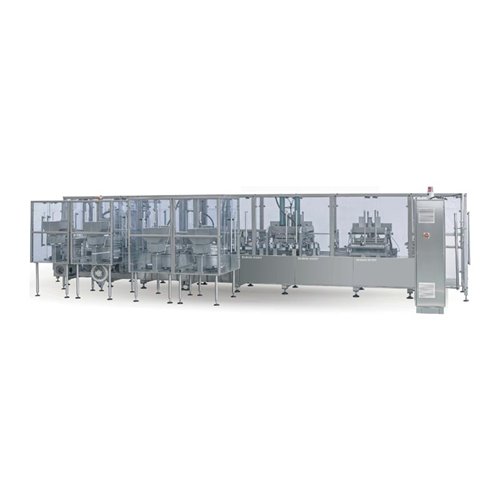

Non Pvc soft bag form fill seal system

Efficiently form, fill, and seal non-PVC infusion bags while ensuring precision and reliability in the packaging of pharmaceutical solutions, enhancing product integrity and reducing contamination risks.

Forms, Fills, and Seals Infusion Bags

The Non PVC Soft Bag Form Fill Seal Machine is a cutting-edge solution from Shinva, tailored for pharmaceutical manufacturers and healthcare institutions. This machine excels in forming, filling, and sealing non-PVC infusion bags, handling both single and multi-chamber designs for products like parenteral nutrient and peritoneal dialysis solutions. It employs a sophisticated oxygen replacement system to enhance product stability and integrates nitrogen charging for controlled film tension and reduced residual oxygen content. Capabilities extend to powder filling and AL foil sealing, catering to the diverse needs of pharmaceutical production.

With a focus on efficiency, this equipment supports high-speed continuous operations, ensuring reliable, stable outputs. Its design accommodates various packaging materials and offers multiple port configuration options for greater flexibility. The system is engineered for seamless integration into existing production lines, using a PLC-controlled interface for ease of automation and remote monitoring. Built with durable, corrosion-resistant materials, it complies with stringent GMP standards, promoting safety and hygiene. The machine’s cleaning process is streamlined with its compact design and accessible components, reducing downtime and maintenance efforts. Shinva offers customization and engineering support to tailor specifications and enhance operational compatibility, ensuring that the machine meets precise production requirements.

Benefits

- Increases production efficiency with high-speed continuous operation.

- Enhances product quality with precise oxygen and nitrogen control systems.

- Reduces operational costs through customizable configurations and easy integration.

- Complies with GMP standards to meet regulatory requirements for safety and hygiene.

- Minimizes maintenance downtime with streamlined cleaning processes and durable construction.

- Applications

- Parenteral nutrient solutions, Flushing fluids, Infusion products, Peritoneal dialysis fluid, Pharmaceuticals

- End products

- Single-chamber infusion bags, Multi-chamber infusion bags, Peritoneal dialysis solution bags, Flushing fluid bags, Parenteral nutrient solution bags

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Filling, AL foil sealing

- Input ingredients

- non PVC materials, packaging materials, anaerobic product, liquid, powder, parenteral nutrient solution, peritoneal dialysis fluid, flushing fluid

- Output ingredients

- single-chamber bags, multi-chamber bags, hard port, soft port, liquid-liquid multi-chamber bag, powder-liquid double-chamber bags, large volume bag

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Bag Forming Process

- Advanced DM mould coating, uniform temperature distribution

- Welding Process

- Three times port welding, double drive

- Packaging Material Compatibility

- Suitable for all kinds of packaging materials

- Bag Type

- Single-chamber / Multi-chamber

- Output Capacity

- High capacity, high cost performance

- Port Type

- Single/double hard port(s), SPT, double soft ports

- Functionality

- Weak welding and nitrogen charging functions

- Operation Stability

- High operation stability with multiple patent designs

- Bag Volume

- Single-chamber, multi-chamber, large volume bag

- Bag forming process

- Mature design, uniform temperature distribution

- Automation level

- Double drive, PLC-controlled

- Changeover time

- Stable and reliable

- Bag oxygen replacement system

- Used for anaerobic product

- Port welding

- Three times port welding

- Form,Fill,Seal process

- Single-chamber or multi-chamber bags

- Film tension control

- Multi-chamber liquid-liquid bags

- Oxygen content control

- Nitrogen charging functions

- Bag-forming to filling head ratio

- 1

- Operation stability

- High operation stability

- Product packaging versatility

- Suitable for various packaging materials

- Packaging material compatibility

- Single-chamber or multi-chamber bags

- Temperature distribution compatibility

- Uniform temperature distribution

- Oxygen replacement compatibility

- Designed for anaerobic products

- Port type compatibility

- Single/double hard port(s), SPT, double soft ports

- Bag type

- Single-chamber / Multi-chamber

- Port type

- Single / Double hard port(s) / Double soft ports

- Bag oxygen replacement system

- Anaerobic product compatibility

- Discharge method

- Form-Fill-Seal process

- Bag port type

- Single/double hard port(s), SPT, double soft ports

- Bag oxygen replacement system

- Anaerobic product capable

- Bag type

- Single-chamber or multi-chamber

- Filling capability

- Liquid-liquid or powder-liquid bags

- Port type

- Diversified combination of port and stopper