High-speed tea bag knot packaging line

Achieve precision and efficiency in tea packaging with a system designed for high-speed knot technology, ensuring superior product quality and versatility across various packaging types, from naked bags to crimped envelopes.

Packages and Knots Tea Bags Efficiently

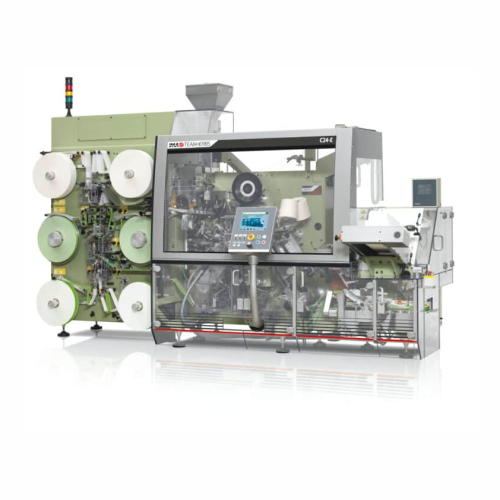

The C24-E from IMA Group is a high-speed tea bag packaging machine featuring knot technology to cater to tea producers and herbal tea manufacturers. This equipment stands out for its versatility in handling various packaging forms, from naked bags to crimped and heatsealed outer envelopes. It operates by employing knot technology, thus eliminating the need for metal staples and enhancing environmental friendliness.

The C24-E can package up to 400 tea bags per minute, accommodating different tea varieties, including black, green, and herbal blends, like chamomile and peppermint, with ease. The machine integrates seamlessly into production lines with its automatic splicing system, single bag rejection, and vibrating feeding system, ensuring continuous operation and high throughput. It features a data-rich HMI for process monitoring and allows for multi-row cartoning, providing adaptability to different packaging needs.

Energy efficiency is achieved through smart motor controls and reduced compressed air consumption, while built-in video cameras and sensors maintain high product quality. For durability and compatibility with various production environments, it supports sustainable packaging materials, adhering to eco-friendly practices. The C24-E is designed with the user in mind, incorporating safety guards and maintenance-friendly features to ensure reliability and ease of use.

Benefits

- Enhances production speed and efficiency by packaging up to 400 bags per minute.

- Minimizes waste and environmental impact with knot technology and sustainable materials.

- Maintains high product quality with integrated quality control systems and real-time monitoring.

- Flexible packaging options support various tea types and packaging styles for diverse market needs.

- Reduces operational downtime with an automatic splicing system and user-friendly HMI interface.

- Applications

- Herbal teas, Herbal blends, Loose leaf tea, Tea, Flavored teas

- End products

- Green tea bags, Earl grey tea bags, Black tea bags, Rooibos tea bags, Chamomile tea bags, Hibiscus tea bags, Lemon-flavored tea bags, Peppermint tea bags, Ginger herbal tea bags, Lavender herbal tea bags

- Steps before

- Herb Preparation, Tea Blending, Raw Material Feeding

- Steps after

- Quality Control, Cartoning, Palletizing

- Input ingredients

- tea, herbs, sustainable packaging materials

- Output ingredients

- naked tea bags, crimped outer envelopes, heatsealed outer envelopes, cartons from flat blanks, eco-friendly packages

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Machine speed

- Up to 400 bags/minute

- Bag type

- Naked bags, crimped and heatsealed outer envelopes

- Tea bag capacity

- Up to approximately 4.0 grams

- Filter bag maximum volume

- Max. 10.5 cubic centimetres

- Power required

- Total installed power 23 kW

- Average power consumption

- 5.5 kW

- Maximum power consumption

- 11.5 kW

- Compressed air pressure

- 6 bar

- Compressed air consumption

- Up to max 650 Nl/min

- Machine net weight

- Max. 4, 250 Kg with crimped/heatsealed outer envelope and cartoning attachment

- Automation

- PC-controlled, motor-driven safety guards

- Efficiency

- Advanced automatic splicing system, single bag rejection

- Sustainability

- Use of sustainable packaging materials

- Working mechanism

- Knot technology

- Automation level

- SMS / HMI controlled with video camera monitoring

- Changeover time

- Not specified

- Energy efficiency

- No metal staples, reduced resource wastage

- Integrated steps

- Weighing, knotting, bag rejection, and packaging

- Batch vs. continuous operation

- Continuous up to 400 bags/minute

- Cleaning method

- Not specified

- Vibrating feeding system

- Minimizes product degradation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PC-controlled, motor-driven safety guards

- Control panel type

- User-friendly HMI with video integration

- Integration possibilities

- PC-controlled motor-driven safety guards

- Packaging versatility

- Naked bags, crimped, and heatsealed envelopes