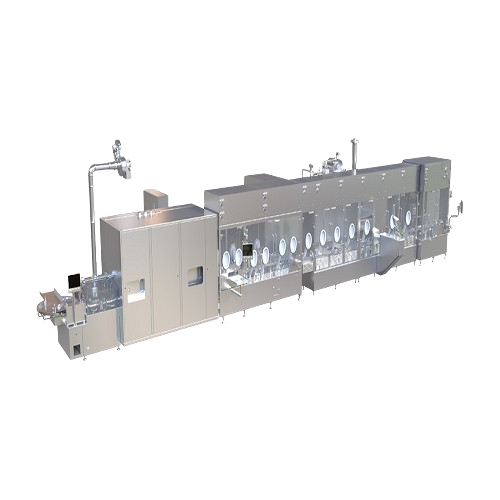

Sterile filling line for liquid and powder

Achieve seamless integration of filling, sterilization, and packaging with this versatile line, designed to handle both liquid and powder formulations, ensuring precise sterility and integrity for high-value pharmaceuticals.

Fills, Lyophilizes, Inspects, and Packages Sterile Products

Leveraging strategic collaborations with Germany’s ROTA and the USA’s M&O Perry, AUSTAR’s integrated sterile filling and freeze-drying system is designed to meet the rigorous demands of pharmaceutical and biopharmaceutical production. This system excels in handling both liquid and powder formulations, ensuring ultimate sterility and precision. It combines advanced washing, filling, and lyophilization processes with seamless automation and high throughput, suitable for producing a variety of end products, including lyophilized injectables, sterile liquid vials, and freeze-dried vaccines. With PLC-controlled operations and remote monitoring capabilities, it integrates effortlessly into existing production lines, while ensuring GMP compliance and reduced contamination risks. Available in corrosion-resistant materials, it supports clean-in-place (CIP) systems for efficient maintenance, offering customizable configurations to fit specific production needs.

Benefits

- Enhances sterility assurance with integrated washing and filling processes.

- Optimizes production efficiency through high-speed, continuous operation.

- Reduces operational costs by minimizing clean room space requirements.

- Ensures regulatory compliance with GMP and industry standards.

- Simplifies maintenance with CIP systems and easy-to-adjust design.

- Applications

- Liquid formulations, Pharmaceutical powder, Development, Biopharmaceuticals, Laboratory research

- End products

- Freeze-dried vaccines, Sterile liquid vials, Monoclonal antibodies, Cell culture media, Powdered antibiotics, Small-batch pharmaceutical formulations, Protein therapies, Clinical trial samples, Lyophilized injectables, Research-grade reagents

- Steps before

- Washing, Cleaning, Container Sterilization

- Steps after

- Capping, Visual Inspection, Sterile Packaging

- Input ingredients

- liquid, powder, containers, WFI, sterile compressed air

- Output ingredients

- sterile filling, lyophilized powder, clean containers, capped containers

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Cleaning method

- Recycled water, WFI and sterile compressed air

- Sterilization efficiency

- Enhanced by differential pressure fast balance system

- Automation

- Integrated freeze-dryer with automatic loading and unloading

- View angle

- 360-degree

- Container handling

- 2R-15R container handling without changing main transport format parts

- Transportation system

- Advanced transport system

- Transport mode

- Prism rail transport mode

- Stoppering technology

- Unique pick-place stoppering technology

- View angle

- 360-degree

- Capping design

- External single blade capping

- Batch size

- Small-lot production

- Filling method

- Manual "needle" filling method

- Filling accuracy

- 100% IPC weighing

- Pressure balance system

- Differential pressure fast balance

- Zone air circulation

- Individual air circulation in infeed, heating, and cooling zones

- Sterile filling capability

- Liquid and Powder

- Automation level

- Integrated automatic loading and unloading

- Changeover capability

- 2R-15R containers without changing parts

- Energy efficiency

- Unique air circulation in heating tunnel

- Breakage rate

- Very low due to unique pincer and servo control

- Container Size and Shape

- 2R-15R containers

- Machine footprint

- Compact

- Viewing angle

- 360-degree

- Container size handling

- 2R-15R

- Design

- Exquisitely designed

- Discharge method

- Pick-place stoppering

- Air circulation zones

- Three zones

- Pincer design

- Unique

- Rail transport mode

- Prism

- Capping design

- Single blade

- Frame size

- Small dimension

- Control panel type

- Advanced transport system

- Integration possibilities

- Integrated with freeze-dryer and automatic loading/unloading device

- Compact footprint

- Small dimension with 360-degree view

- Unique design elements

- Unique pincer design and prism rail transport mode

- Loading/unloading device compatibility

- Automatic

- Stoppering technology

- Pick-place stoppering technology

- Capping adjustment

- Single blade capping design

- Needle filling method

- Manual needle filling