Making Gels

Find innovative production technology for making gels and connect directly with world-leading specialists

The easiest and most commonly used method of making gels is mixing gelling agents with water to form a weakly cohesive internal structure. The gel production process is pretty linear and straightforward, from mixing hydrocolloids and water to labeling and sealing containers.

Select your gels process

Tell us about your production challenge

Do you need a gel making machine for gel production?

To manufacture gel, you simply need to mix gelling agents with appropriate proportions of water to form a semi-solid aerosol. Thickening (or gelling) agents help increase the viscosity of liquids without substantially altering their other properties. On their part, hydrocolloids used in making gels are usually in powder form but are derived from various sources and origins, including plants, marine, biotechnological, cellulose, and synthetic.

You need different equipment to manufacture gel depending on your intended product’s type and applications. For starters, a small-scale dispersion machine is an important tool, since homogenization is a game-changer. Further, in the carefully-controlled arena of pharmaceutical production, GMP (Good Manufacturing Practice) washing solutions are essential. It cleans production equipment in regulated pharmaceutical-manufacturing facilities. Moreover, if you’re planning on large-scale production, you must have filling and labeling machines.

How gels are useful

Gels have a wide range of uses and can be pharmaceutical and cosmetic. Cosmetic gels feature prominently in the manufacturing of personal care products such as hair styling gels. Likewise, pharmaceutical gels help in the making of painkillers and ointments. The production process for manufacturing both types of gel is largely similar, but zero cross-contamination between production batches is significantly more important in the production of pharmaceutical products.

What you should know about regulations for gel production

Regulations for the production of cosmetic and pharmaceutical gels differ in specification and enforcement. Cosmetic GMPs guide the production and sale of cosmetic gels. These are a set of guidelines highly encouraged by health regulatory bodies in several countries. On the other hand, several countries have enacted legislation guiding the production of pharmaceutical gels, in addition to pharmaceutical products regulation. The World Health Organization (WHO) also has standards promoting and regulating the production of pharmaceutical products.

The FDA highlights differences in regulations between cosmetic and pharmaceutical products, which can apply to gel production as well. For instance, cosmetic products do not require FDA approval before they can go on sale whereas pharmaceutical products must receive premarket approval. Also, failure to follow GMP requirements adulterates pharmaceutical products, while no regulations stipulate specific GMP requirements for cosmetic products.

Gel making machines and the homogenization process

Homogenization can make or mar your efforts. It serves several purposes such as reduction of particle size, dispersion, dissolution, mixing, emulsification, and encapsulation. The homogenization process involves the use of pressure to mix two items (in this case, powder and water) to create a uniform emulsion. While it’s certainly possible, it’s not advisable for you to homogenize your gel by hand. Since the homogenization process is so exacting, there are industrial, high-pressure homogenization equipment to help make the process smoother.

Processing steps involved in gels making

Which gels technology do you need?

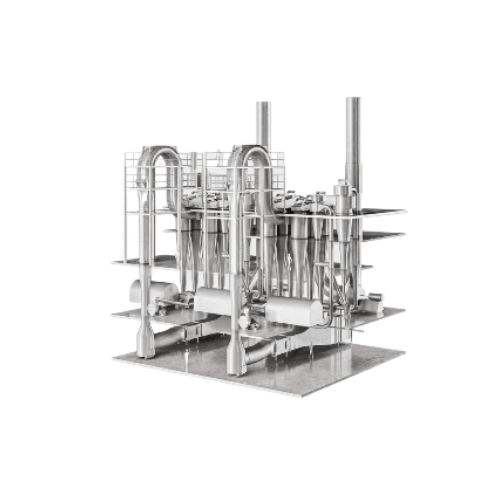

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

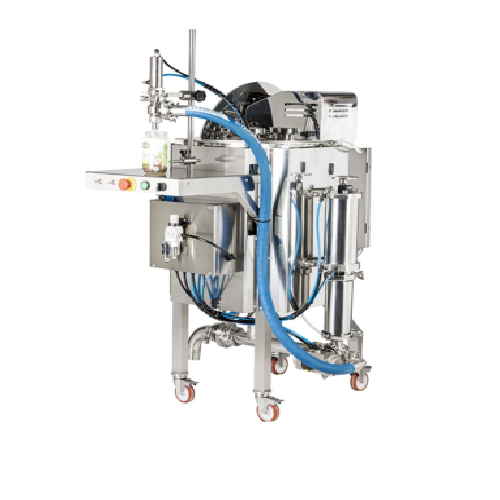

Vacuum turboemulsifier for small-scale production

Optimize your product development with versatile vacuum turboemulsifier...

Automatic rotary jar filling and capping system

Optimize your personal care product line by efficiently filling and cappin...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

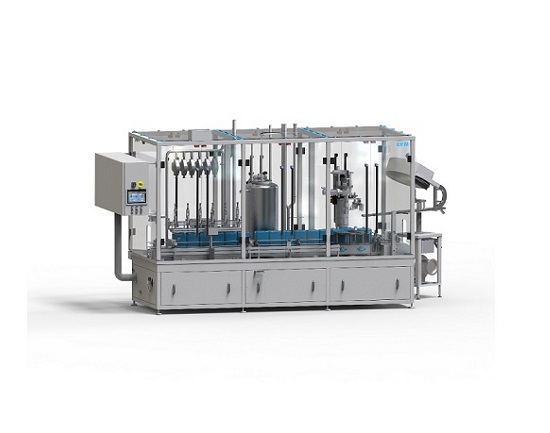

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

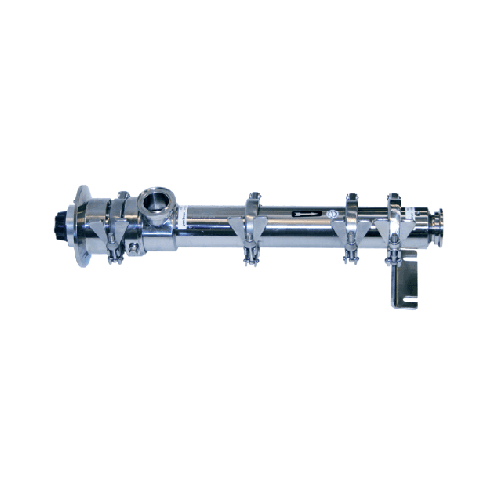

Hygienic pipeline product recovery system

Efficiently recover valuable residuals from pipelines while streamlining your cl...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

Hydroalcoholic gel mixing system

Ensure seamless production of hydroalcoholic gels with an advanced mixing system designed f...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Small batch mixer granulator blender

Effortlessly manage small batch mixing, blending, and granulation with a compact solut...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

Undervacuum homogenizer for cosmetic and pharmaceutical creams

Optimizing the production of creams and lotions, this und...

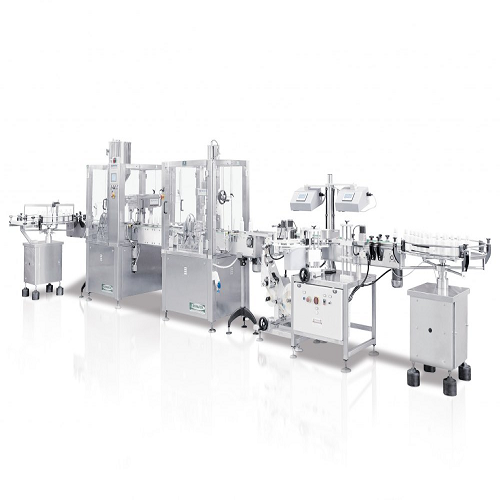

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

High viscosity product mixer

Struggling with mixing high viscosity products like creams and gels? This co-axial mixer enhanc...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed f...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Single-chamber freeze dryer for liquid products

When precision drying of sensitive liquids is crucial, this single-chamber...

Vacuum homogenizers for cosmeto-pharma and fine chemistry

Bring precision and efficiency to your formulation processes w...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

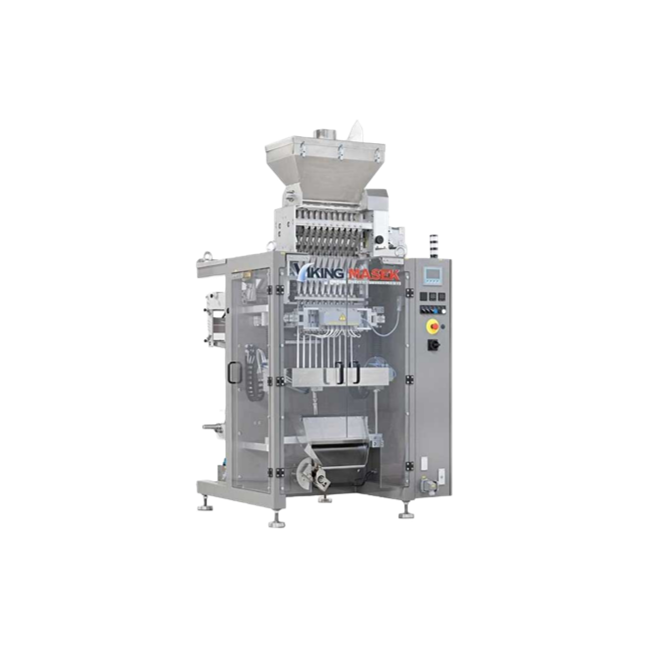

High-capacity stick pack packaging solution

Enhance your production efficiency by packaging diverse products like powders ...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Automatic tube filler for multi-color coextruded products

Achieve precise dual- or tri-color product designs with except...

Automatic tube filling solution for high-volume production

Effortlessly streamline your production with this high-speed ...

Turbo emulsifier for creams, gels, toothpastes

Achieve perfect emulsification and homogenization for your creams, gels, an...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Feed hopper for volumetric feeders

Optimize product consistency while handling a variety of viscosities with this feed hopp...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

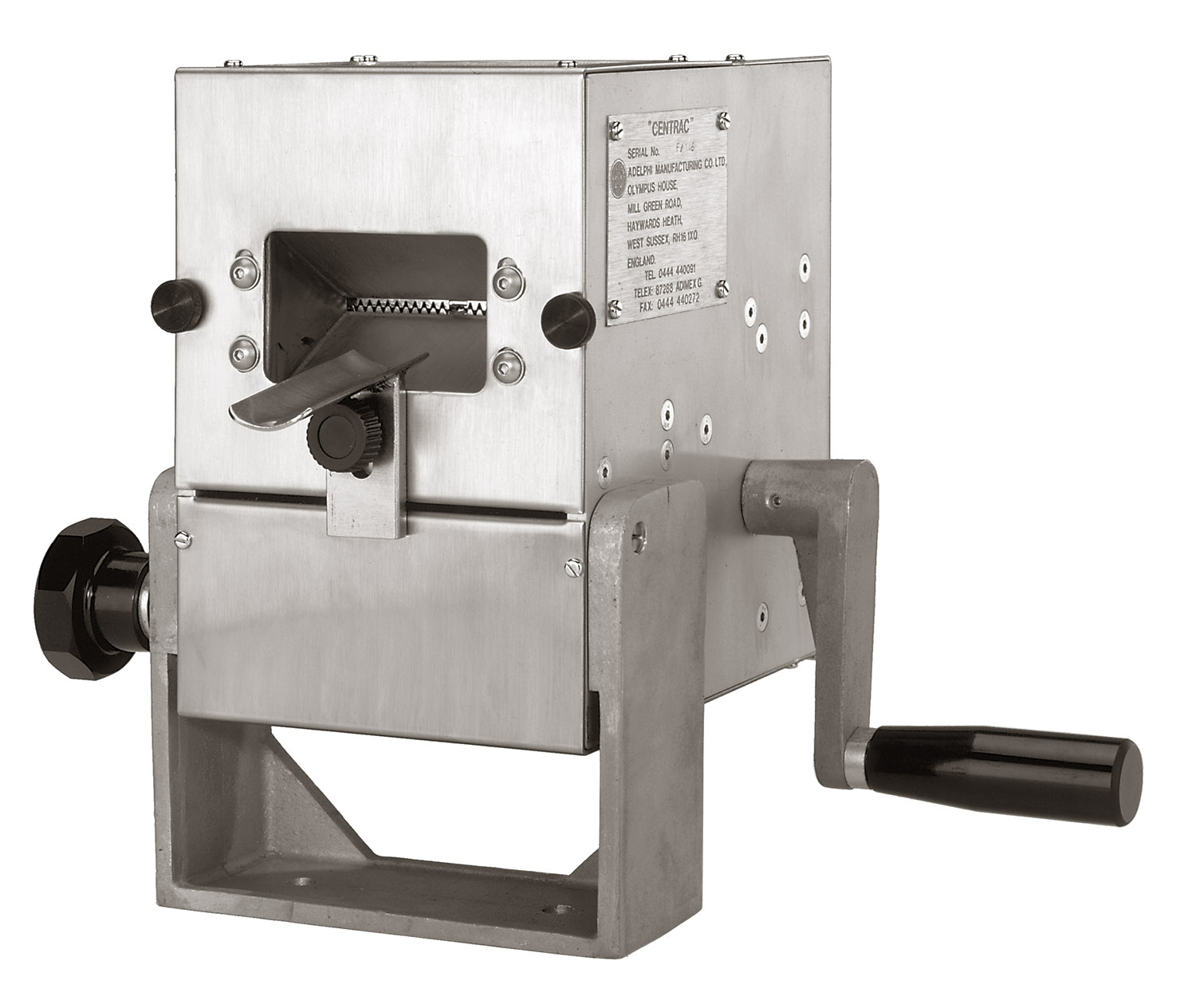

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Colloid mill for particle size reduction and emulsification

Achieve precise particle size reduction and stable emulsions...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

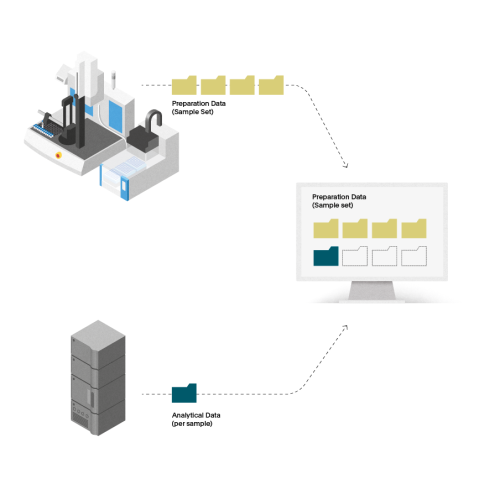

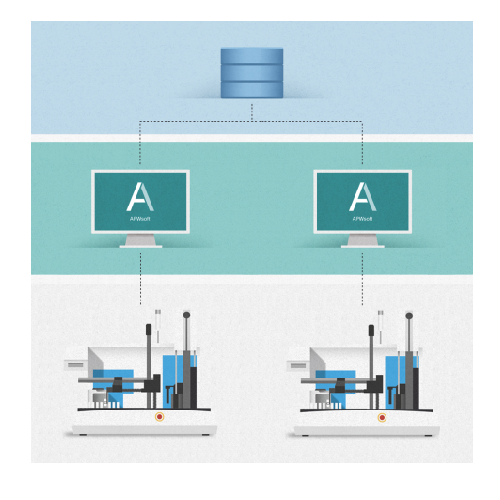

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell ...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Powder flow tester for pharmaceutical powder flowability

Quickly assess powder flow characteristics to ensure consistent ...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

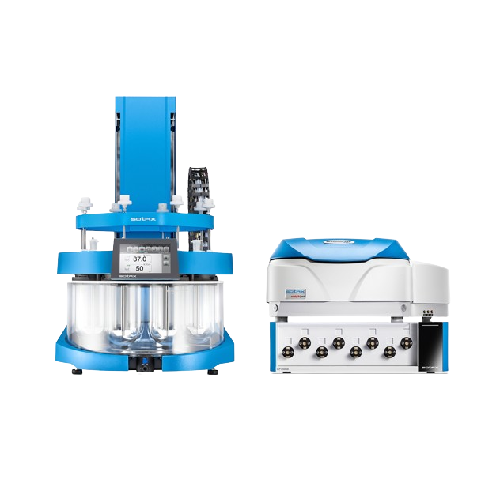

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

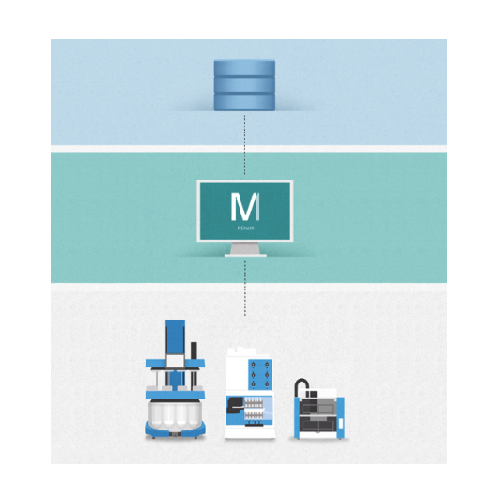

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

High shear batch mixer for industrial mixing

Optimize your production cycle with this high shear batch mixer, designed to ...

Filling and sealing multi-well cassettes for molecular diagnostics

Streamline your small to medium-scale diagnostic pro...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Vacuum mixer for suspensions

The production of high quality pharmaceuticals often requires mixing of suspensions and similar...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

A two-component filling application tube filler

A wide variety of pharmaceutical, cosmetic and food products require tube-...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

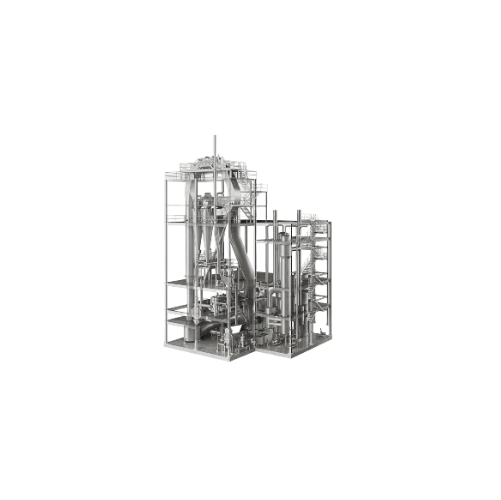

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

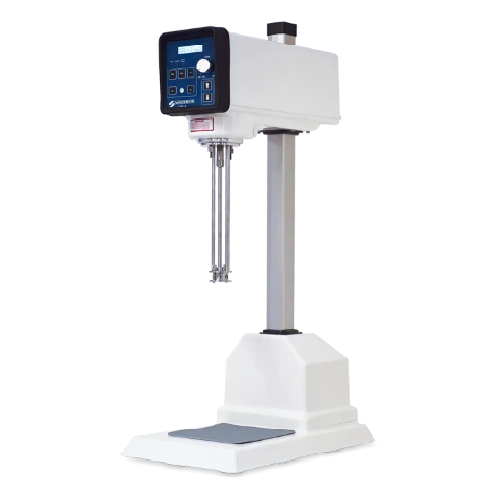

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...